You can display the results for solids graphically using the Solids navigator category. You will find the numerical results of solids in the Results by Solid table category.

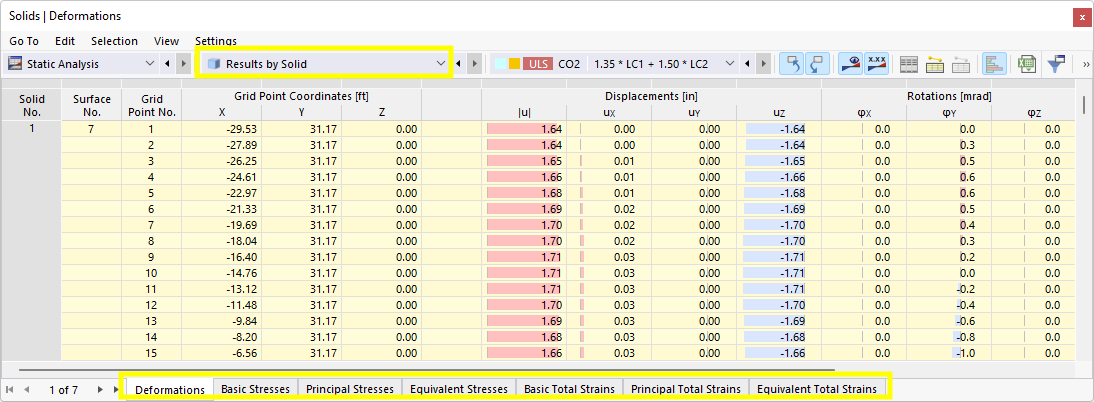

Deformations

The image Results by Solid in Table shows the table with deformations of the boundary surfaces. Displacements and rotations are displayed in the surface grid points (see the chapter Surfaces ).

The deformations have the following meaning:

| |u| | Absolute value of the total displacement |

| uX | Displacement in the direction of the global axis X |

| uY | Displacement in the direction of the global axis Y |

| uZ | Displacement in the direction of the global axis Z |

| φX | Rotation about the global axis X |

| φY | Rotation about the global axis Y |

| φZ | Rotation about the global axis Z |

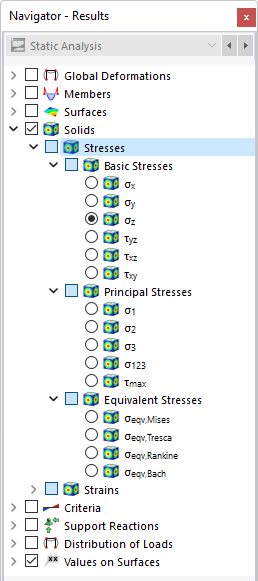

Stress

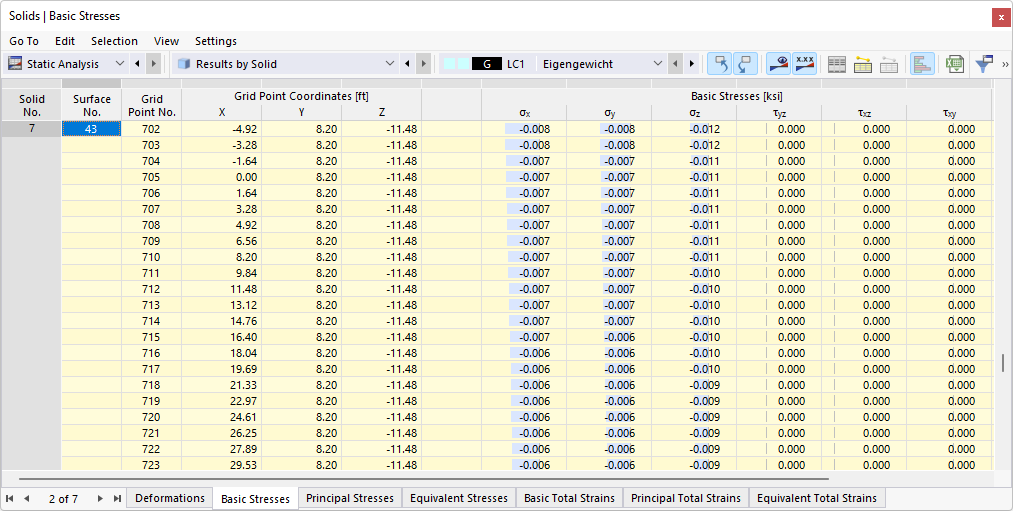

In the navigator, define the stresses to be displayed on the boundary surfaces of solids. The table lists the stresses of these surfaces according to the specifications set in the Result Table Manager .

The solid stresses are divided into the following categories:

- Basic stresses

- Principal stresses

- Equivalent stresses

Unlike surface stresses, solid stresses cannot be described by simple equations. The basic stresses σx, σy, and σz as well as the shear stresses τyz, τxz, and τxy are determined directly by the analysis core.

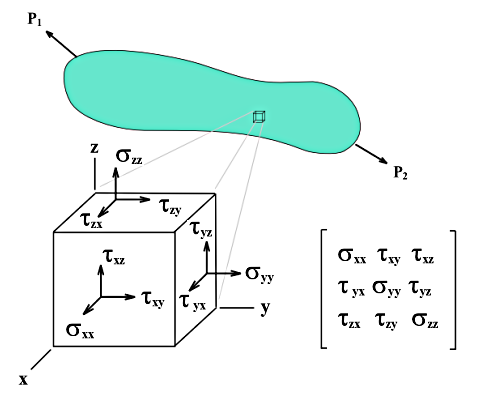

If a cube with the edge lengths dx, dy, and dz is cut from a 3D object with multiaxial loading, the stresses in each cubic surface can be split into normal and shear stresses. Neglecting the spatial force and also the stress differences on parallel surfaces, the stress state can be described by nine stress components in the cube's local coordinate system.

The matrix of the stress tensor is the following:

The principal stresses σ1, σ2, and σ3 result from the eigenvalues of the tensor as follows:

The maximum shear stress" τmax is determined according to Mohr's circle:

The equivalent stresses σv according to

von Mises

can be determined by two equivalent formulas.

To determine the equivalent stress σv according to Tresca , the differences from the principal stresses are examined in order to determine the maximum value.

The equivalent stresses σv according to Rankine is determined from the greatest absolute values of the principal stresses.

To determine the equivalent stress σv according to Bach , the principal stress differences are examined, taking into account Poisson's ratio ν, in order to determine the maximum value.

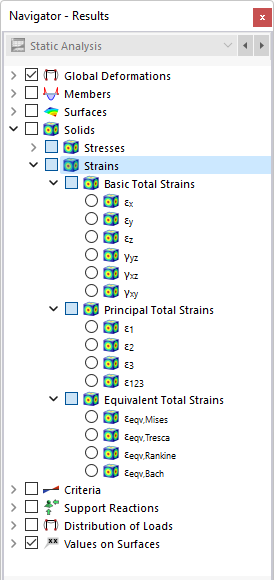

Strains

In the navigator, define the strains to be displayed on the boundary surfaces of solids. The table lists the strains of these surfaces according to the specifications set in the Result Table Manager .

The solid strains are divided into the following categories:

- Basic total strains

- Principal total strains

- Equivalent total strains

The basic total strains including shear strains are determined directly by the computation kernel. The general definition of the tensor for the spatial strain state is as follows:

The elements of the tensor are defined as follows:

The principal total strains ε1, ε2, and ε3 are determined from the basic strains.

The equivalent total strains εv are determined according to four different stress hypotheses as follows.

|

R |

Matrix (see below) |

|

R |

Matrix (siehe unten) |

|

R |

Matrix (see below) |

.png?mw=760&hash=71627fe33fddc42ab64faca4d036ceecb28da92c)

.png?mw=760&hash=b95435bbf9c07c7f89896b47d2be8a7f2444ee35)