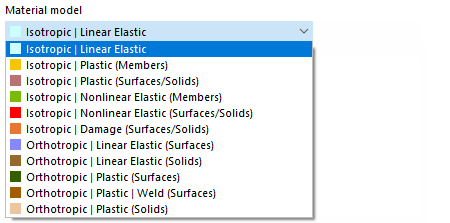

Material Models

If the Nonlinear Material Behavior analysis add-on (requires a license) is activated in the Model Base Data, further options are available in the list of material models in addition to the "Isotropic | Linear Elastic" and "Orthotropic | Linear Elastic" material models.

Calculation Method

If you use a nonlinear material model, an iterative calculation is always performed. Depending on the material model, a different relation between the stresses and strains is defined.

The stiffness of the finite elements is repeatedly adjusted in the course of the iterations until the stress-strain relation is complied with. The adjustment is always carried out for an entire surface or solid element. The Constant on mesh elements smoothing type should, therefore, always be used when evaluating stresses.

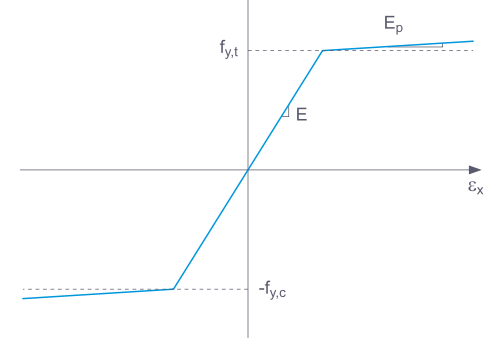

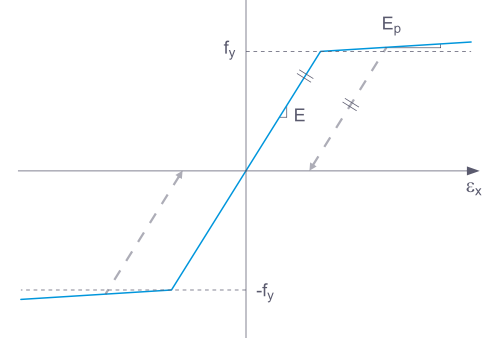

Some material models in RFEM are labeled as "Plastic", others as "Nonlinear Elastic". If a structural component with a nonlinear elastic material is relieved of loads again, the strain decreases along the same path. When the load is completely removed, no strain remains.

When a component is relieved of loads with a plastic material model, a strain remains after complete unloading.

Loading and unloading can be simulated using the Construction Stages Analysis add-on.

Background information about nonlinear material models can be found in the technical article Yield Laws in Isotropic Nonlinear Elastic Material Model.

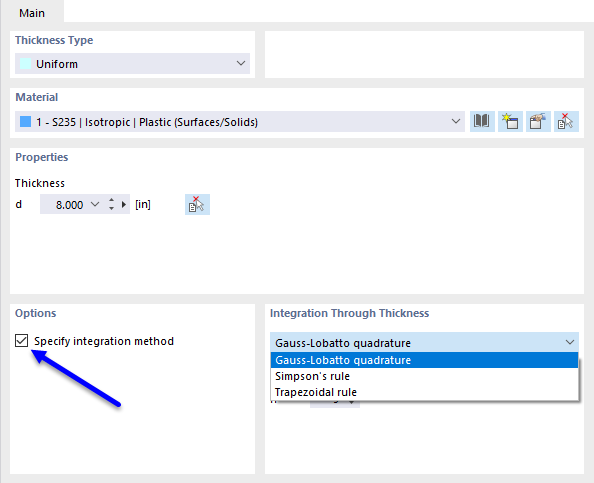

The internal forces in plates with nonlinear material result from the numerical integration of the stresses over the plate thickness. To define the integration method for the thickness, select the Specify integration method option in the "Edit Thickness" dialog box. The following integration methods are available:

- Gauss-Lobatto quadrature

- Simpson's rule

- Trapezoidal rule

You can also specify the "Number of integration points" from 3 to 99 via the plate thickness.

Isotropic Plastic (Members)

If you select Isotropic | Plastic (Members) from the "Material model" drop-down list, the tab for entering the nonlinear material parameters is activated.

In this tab, you define the stress-strain diagram. The following options are available:

- Basic

- Bilinear

- Diagram

If you select Basic, RFEM uses a bilinear material model. The values from the material library are used for the modulus of elasticity E and the yield strength fy. For numerical reasons, the diagram branch is not exactly horizontal, but has a small slope Ep.

If you want to change the values for the yield strength and the modulus of elasticity, activate the User-defined material check box in the "Main" tab.

For a bilinear definition, you can also enter a value for Ep.

More complex relations between stress and strain can be defined by means of the Stress-strain diagram. If you select this option, the "Stress-Strain Diagram" tab is displayed.

Define a point for the stress-strain relation in each table row. You can select how the diagram continues after the last definition point in the "Diagram end" list below the diagram:

In the case of "Tearing", stress after the last definition point jumps back to zero. "Yielding" means that stress remains constant when strain increases. "Continuous" means that the graph continues with the slope of the last section.

Isotropic Plastic (Surfaces/Solids)

If you select Isotropic | Plastic (Surfaces/Solids) from the "Material model" drop-down list, the tab for entering the nonlinear material parameters is activated.

First, select the "Stress failure hypothesis". The following hypotheses are available for selection:

- von Mises (von Mises yield criterion)

- Tresca (Tresca yield criterion)

- Drucker-Prager

- Mohr-Coulomb

If you select von Mises, the following stresses are used in the stress-strain diagram:

- Surfaces

- Solids

According to the Tresca hypothesis, these stresses are used:

- Surfaces

- Solids

According to the Drucker-Prager hypothesis, the following stress is used for surfaces and solids:

|

σc |

Limit stress for compression |

|

σt |

Limit stress for tension |

According to the Mohr-Coulomb hypothesis, the following stress is used for surfaces and solids:

Isotropic Nonlinear Elastic (Members)

The functionality largely corresponds to that of the Isotropic Plastic (Members) material model. But in contrast to it, no plastic strain remains after the load is removed.

Isotropic Nonlinear Elastic (Surfaces/Solids)

The functionality largely corresponds to that of the Isotropic Plastic (Surfaces/Solids) material model. But in contrast to it, no plastic strain remains after the load is removed.

Isotropic Damage (Surfaces/Solids)

In contrast to other material models, the stress-strain diagram for this material model is not antimetric to the origin. This material model can, therefore, be used to model the behavior of steel fiber-reinforced concrete, for example. Detailed information on modeling steel fiber-reinforced concrete can be found in this technical article on the Material Properties of Steel-Fiber-Reinforced Concrete.

The isotropic stiffness is reduced with a scalar damage parameter. This damage parameter is determined from the stress curve defined in the Diagram. This does not take the direction of the principal stresses into account; rather, the damage occurs in the direction of the equivalent strain, which also covers the third direction perpendicular to the plane. The tension and compression areas of the stress tensor are treated separately. Different damage parameters apply in each case.

The "Reference element size" controls how the strain in the crack area is scaled to the length of the element. With the default value zero, no scaling is performed. Thus, the material behavior of the steel fiber-reinforced concrete is modeled realistically.

You can find theoretical background information on the material model "Isotropic Damage" in the technical article Nonlinear Material Model Damage.

Orthotropic Plastic (Surfaces) / Orthotropic Plastic (Solids)

The material model according to "Tsai-Wu" unifies plastic with orthotropic properties. This allows for special modeling of materials with anisotropic characteristics, such as fiber-reinforced plastics or timber.

If the material is plastified, the stresses remain constant. A redistribution takes place depending on the stiffnesses that are present in the individual directions.

The elastic area corresponds to the material model Orthotropic Linear Elastic (Solids). The following yielding condition according to Tsai-Wu applies to the plastic zone:

- Surfaces

- Solids

All strengths are to be defined as positive.

The yield condition can be imagined as an elliptical surface in the six-dimensional stress space. If one of the three stress components is applied as a constant value, the surface can be projected onto a three-dimensional stress space.

If the value for fy(σ) according to the Tsai-Wu, plane stress state equation is less than 1, the stresses are in the elastic range. The plastic range is reached as soon as fy(σ) = 1. Values greater than 1 are not allowed. The model behavior is ideal-plastic, which means there is no stiffening.

Orthotropic Plastic Weld (Surfaces)

This material model is used in analyses with the Steel Joints add-on to represent the behavior of welds in accordance with standards. Only stresses that correspond to the stress components σ⊥, τ⊥, and τ|| of the weld occur in the equivalent surface. In the other stress directions, the stiffness of the equivalent surface approaches zero.

In the "Orthotropic | Plastic | Weld (Surfaces)" tab, you can define the parameters for taking plastic strain hardening for welds into account, such as the limit values fekv and fx for the stress analysis according to the "Directional Method" as per EN 1993-1-8 [1] for welds, modified by a plastic component (see also the technical article Design of Fillet Welds).

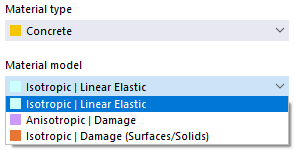

Concrete

The nonlinear material models "Anisotropic | Damage" and "Isotropic | Damage (Surfaces/Solids)" are available for the "Concrete" material type.

The two material models are described in the chapter Material Type and Material Model of the Concrete manual or above in the Isotropic Damage section.

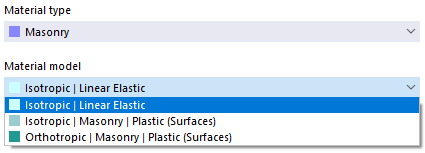

Masonry

If the Masonry Design add-on (requires a license) is activated in the Model Base Data, the nonlinear material models "Isotropic | Masonry | Plastic (Surfaces)" and "Orthotropic | Masonry | Plastic (Surfaces)" are available for selection for the "Masonry" material type.

Both material models are described in the chapter Materials of the Masonry Design manual.