Materials are required to define cross-sections. The material properties affect the stiffnesses of members.

Name

You can define any name for the material. If the description matches an entry in the library, RSTAB imports the stored material properties. To select a material from the library, click the

![]() button at the end of the input line. The import of materials is described in the chapter Material Library.

button at the end of the input line. The import of materials is described in the chapter Material Library.

For materials from the library, the "Basic Material Properties" are set by default and cannot be changed. If you want to use user-defined properties of the material, select the User-defined material check box in the "Options" section (see the section User-Defined Material).

Main

The Main tab manages the basic material parameters. It also provides control options for special properties that you can define in additional tabs.

Categories

In this section, you define the material type and material model.

Material Type

The material type controls which parameters and factors are relevant for the design. This classification also defines the partial safety factors of the material, which are taken into account for the design, depending on the standard.

For a material taken from the library, one of the following material types is preset.

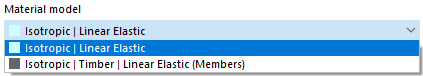

Material Model

The list contains the material models “Isotropic | Linear Elastic” and “Isotropic | Timber | Linear Elastic (Members)” (for timber materials).

Isotropic | Linear Elastic

The linear-elastic stiffness properties of the material do not depend on directions. They can be described as follows:

|

E |

Modulus of elasticity |

|

G |

Shear modulus |

|

ν |

Poisson's ratio |

The following conditions apply:

- E > 0

- G > 0

- ν > -1

Isotropic | Timber | Linear Elastic (Members)

This material model can be selected for materials of the "Timber" type. It allows you to represent, for example, the properties of an oriented strand board (OSB) in a member model, including different stiffnesses depending on the installation position. You can define the position of the board in the "Isotropic Timber | Linear Elastic (Members)" tab using the two lists.

Basic Material Properties

This section of the “Main” tab contains the most important properties of the material.

Modulus of Elasticity

The modulus of elasticity E describes the ratio between normal stress and strain.

Shear Modulus

The shear modulus G, also known as the sliding modulus, is the second parameter for describing the elastic behavior of a linear, isotropic, and homogenous material. In this case, the deformation is based on shear stress.

Poisson's Ratio

Poisson's ratio ν is required to determine the transverse strain. Generally, Poisson's ratio for isotropic materials is between 0.0 and 0.5. Therefore, for a value of 0.5 or higher (for example, rubber), it is assumed that the material is not isotropic.

The relation between the modulus of elasticity, shear modulus, and Poisson's ratio for an isotropic material is described in the equation Poisson's Ratio.

When entering a user-defined material with its isotropic properties, RSTAB determines the Poisson's ratio based on the values of the modulus of elasticity and the shear modulus. If necessary, you can change this presetting in the "Definition type" list.

Definition Type

| E | G | (ν) | The Poisson's ratio is determined from the modulus of elasticity and the shear modulus. |

| E | (G) | ν | The shear modulus is determined from the modulus of elasticity and the Poisson's ratio. |

| E | G | ν | The modulus of elasticity, shear modulus, and Poisson's ratio are independent of each other. |

Specific Weight / Mass Density

The specific weight γ describes the weight of the material per volume unit. The specification is especially important for the "Self-weight" load type. The automatic self-weight of the model is determined from the specific weight and the cross-sectional areas of the used members.

The density ρ describes the mass of the material per volume unit. This information is required for dynamic analyses.

Coefficient of Thermal Expansion

The coefficient of thermal expansion α describes the linear correlation between changes in temperature and length (elongation of material due to heating, shortening due to cooling).

The coefficient of thermal expansion is relevant for the "Temperature" and "Temperature change" load types.

Options

The check boxes in this section of the “Main” tab allow you to influence the material properties. After activating an option, new tabs are added.

User-Defined Material

For materials from the library, the material properties are preset. Therefore, they cannot be changed directly in the input boxes. To adjust the properties of a material, activate the “User-defined material” check box. This makes the input boxes for the basic material properties accessible in the “Main” tab. You can also change the design-specific properties in the “Material Properties” tab (see the image Adjusting Material Properties). In the “Stiffness Modification” tab, you can scale the E and G moduli globally by a factor (see the image Adjusting Material Stiffness).

Temperature-Dependent

To define a linear elastic material with temperature-dependent stress-strain properties, activate the “User-defined” and “Temperature-dependent” check boxes. You can then define the temperature-dependent material properties in the Temperature-Dependent tab.

Material Properties

The “Material Properties” tab contains all material properties that are relevant for structural analysis and design in the add-ons.

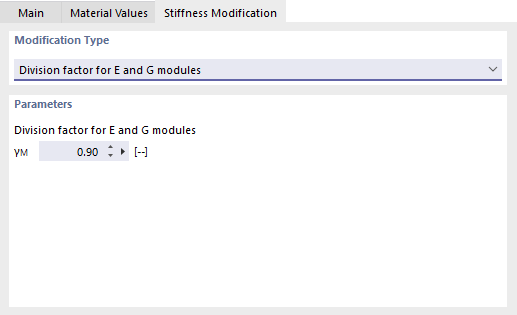

Stiffness Modification

The Stiffness modification tab is displayed if you have checked the User-defined material option in the “Main” tab. Here you can adjust the stiffness of the material globally, for example, to consider safety factors or reduced material properties.

There are two options to select from in the “Modification type” section:

- Division factor for E and G moduli

- Multiplier factor for E and G moduli

In the "Parameters" section, enter the factor by which the material stiffness is to be adjusted.

Temperature-Dependent

The Temperature-Dependent tab is displayed if you have selected the User-defined material and Temperature-dependent options in the “Main” tab. Here you can describe the temperature-dependent properties of the material. The temperature-dependent material properties are taken into account for objects that are thermally stressed by temperature or temperature change. When calculating the temperature loads, the final temperature of the respective step is used.

In the "Temperature-Dependent Property" list, select a material property; for example, the modulus of elasticity. Then, use the

![]() button to create the required table rows so that you can enter the temperatures with the corresponding values row by row. You can use the

button to create the required table rows so that you can enter the temperatures with the corresponding values row by row. You can use the

![]() button to import data from an Excel spreadsheet.

button to import data from an Excel spreadsheet.

The "Reference Temperature" defines the stiffnesses for the objects that have no temperature loads. When a reference value, for example, of 300 °C is set, the reduced modulus of elasticity of that point of the temperature curve is applied for all members.

User-Defined Material Library

You can save a user-defined material in a library as a template. This means that it is not necessary to define the material properties again in other projects.

Saving Material

To save the current material as a user-defined material, click the button at the bottom of the “Basic Material Properties” section after setting the material properties.

The “New User-Defined Material” dialog box appears.

Enter the name of the material in the “Name” text box. If necessary, you can adjust the material properties. Click OK to save the user-defined material in the library.

Importing Material

To import a user-defined material from the library, click the

![]() button in the “Basic Material Properties” section.

button in the “Basic Material Properties” section.

The “Edit User-Defined Material” dialog box appears. In this library with your saved materials (see the image Dialog Box “New User-Defined Material”), you can select the relevant entry and then click OK to apply it.

If you have imported a user-defined material and want to change its properties in general, you can adjust the material properties using the

![]() button (in the “Basic Material Properties” section) in the library.

button (in the “Basic Material Properties” section) in the library.