You need a section to describe the properties of a member: The section properties and the assigned material properties affect the stiffness of the member.

Not every section that has been defined needs to be used in the model. This way, you can model variants quickly, without deleting cross-sections. However, it is not possible to renumber the sections.

Name

You can define any name for the section and specify its cross-section properties. If the description matches an entry in the library, RSTAB imports the stored properties. To select the cross-section from the library, click the

![]() button at the end of the input line. The import of sections is described in the chapter Section Library.

button at the end of the input line. The import of sections is described in the chapter Section Library.

For cross-sections from the library, the section properties are set by default and cannot be changed. The shear areas and the dimensions for non-uniform temperature loads are exceptions.

For a user-defined section name, you have to define all section properties manually. You can then use the cross-section to determine the internal forces and moments. However, the design of this cross-section is impossible, because no stress points can be defined.

Main

The Main tab manages the basic section parameters.

Material

It is necessary to assign a material to each cross-section. You can select it from the list of already defined materials. The buttons next to the input text box allow you to select a material from the library or to define a new one (see the chapter Materials).

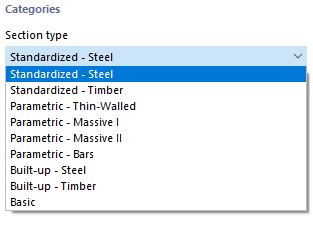

Categories

Section type

For cross-sections from the library, the "cross-section type" is preset according to the usual classifications there (see the chapter Section Library). User-defined cross-sections are assigned to the "Basic" type.

Manufacturing type

The production method of a cross-section is displayed for the cross-sections from the library. It controls certain design specifications; for example, the buckling curves of cold-formed hollow sections.

Options

Deactivate shear stiffness

Taking shear stiffness into account leads to an increase in deformation due to shear forces. Shear deformation plays a minor role in rolled and welded cross-sections. For solid and timber cross-sections, however, we recommend considering the shear stiffnesses for the deformation analysis.

Deactivate warping stiffness

The check box for taking the warping stiffness into account is available if the Torsional Warping add-on is activated in the Base Data. In this case, you can control whether the warping stiffness of the cross-section is applied in the calculation with seven degrees of freedom.

Section rotation

The section rotation describes the angle by which the cross-section is rotated. You can define the rotation angle α' in the Section Rotation tab.

For unsymmetric cross-sections, this tab also provides options to "Mirror" the cross-section. This way, you can put an L-section in the correct position, for example.

When importing a cross-section from the library or RSECTION, you do not need to take care of the section rotation angle α'. RSTAB imports the angle automatically. For user-defined cross-sections, however, you have to determine the principal axis angle manually and adjust the position using the section rotation.

Hybrid

The "Hybrid" option is available for cross-sections of the "Parametric – Massive II" type as well as for RSECTION cross-sections consisting of several materials. In the Hybrid tab, you can assign material properties to the components of built-up timber cross-sections.

Thin-walled model

The "Thin-walled model" check box allows you to control the analysis according to which the cross-section properties are determined for cross-sections of the "Standardized – Steel" and "Parametric – Thin-Walled" type. For a massive section, for example, the shear areas and the torsional moment of inertia are determined according to a different method, since the analytical solution only applies to thin-walled sections.

US notation for section properties

The symbols of the cross-section properties differ according to European and American conventions. You can use the check box to control whether the statical moments are designated as S or Q, for example.

Stress smoothing to avoid singularities

Stress smoothing is primarily suitable for composite timber sections in order to avoid singularities in the connection areas. In these areas, shear stresses often lead to stress peaks, which have an unfavorable effect on the design. This function allows you to achieve a better distribution of stresses.

Section Properties

The most important cross-section properties are listed in this section. Further parameters can be found in the Section Values tab.

Sectional areas

The cross-sectional areas are subdivided into the total area "Axial A", and the areas for "Shear Ay" and "Shear Az". The shear area Ay is related to the moment of inertia Iz; the shear area Az is related to Iy accordingly.

The following technical article provides information on determining shear areas:

https://www.dlubal.com/en/support-and-learning/support/knowledge-base/000966

The shear areas affect the shear deformation, which should be taken into account especially for short, massive members. If you change the shear areas, you should avoid extremely small values: The shear areas are included in the denominator of equations, so numerical problems may arise.

Area moments of inertia

The second moments of area define the section stiffness with regard to loading by moments: The torsional constant IT describes the stiffness against rotation about the longitudinal axis. The second moments of area Iy and Iz describe the stiffnesses against bending about the local axes y and z. Axis y is considered to be the "major" axis. The warping moment of inertia Iω is used to describe the resistance to warping.

For unsymmetric cross-sections, the second moments of area are displayed around the principal axes u and v of the cross-section. The local section axes are shown in the cross-section graphic.

You can adjust the section areas and moments of inertia using factors that you define as a section-specific "structure modification" (see chapter Structure Modifications).

Inclination of principal axes

The inclination of principal axes describes the position of the principal axes in relation to the standard principal axis system of symmetrical cross-sections. For unsymmetrical sections, this is the angle α between the axis y and the axis u (positive in clockwise direction). The principal axes are called y and z for symmetric cross-sections, and u and v for unsymmetric cross-sections (see the image Section Properties and Axes).

The principal axis inclination is determined according to the following equation:

|

α |

Hauptachsenwinkel |

|

Iyz |

Biaxiales Flächenträgheitsmoment |

|

Iz |

Trägheitsmoment um die z-Achse |

|

Iy |

Trägheitsmoment um die y-Achse |

The inclination of principal axes for sections from the library cannot be edited. However, you can rotate the section around a user-defined angle: Select the "Section rotation" check box in the "Options" section (see Section Rotation).

Dimensions (for non-uniform temperature loads)

The dimensions with regard to the width b and height h of the cross-section are required for the calculation of temperature loads.

Section Values

In the Section Values tab, the properties of the cross-section are listed in detail.

The section properties of parametric cross-sections are determined using RSECTION.

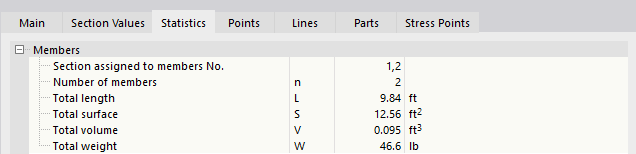

Statistics

The Statistics tab provides an overview of the members available in the model that use that cross-section. For example, you can use the "Total weight" indication for steel schedules or cost estimation.

Points

The geometry of the section is defined by points. They also form the basis for lines.

The coordinates of the definition points are listed in a table. When you select a row, that point is shown in red in the cross-section graphic. For thin-walled sections, the definition points on the center lines are marked with a + symbol. Generated control points for arcs are indicated by a lock symbol with +. The points on the cross-section edges result from the element thicknesses.

For arcs, you can view the arc parameters in the "Parameters" section next to the point coordinates.

Lines

The points of the cross-section are connected by lines, so the geometry of the section is defined by its outline. The lines also form the basis for parts.

The definition points of the lines, as well as the line types and lengths, are listed in a table. When you select a row, that line is shown in red in the cross-section graphic.

Parts

One or more parts are created from the contour lines of the section.

For each cross-section part, the table shows the definition lines, material, cross-section area, and mass per unit length.

Stress Points

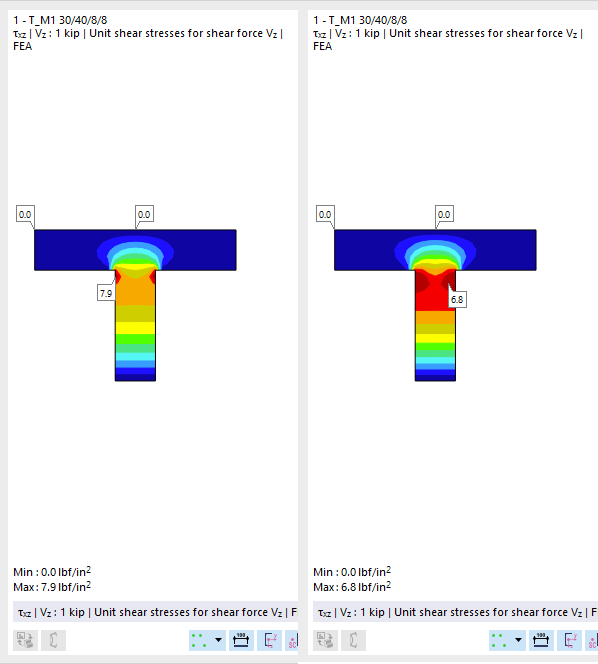

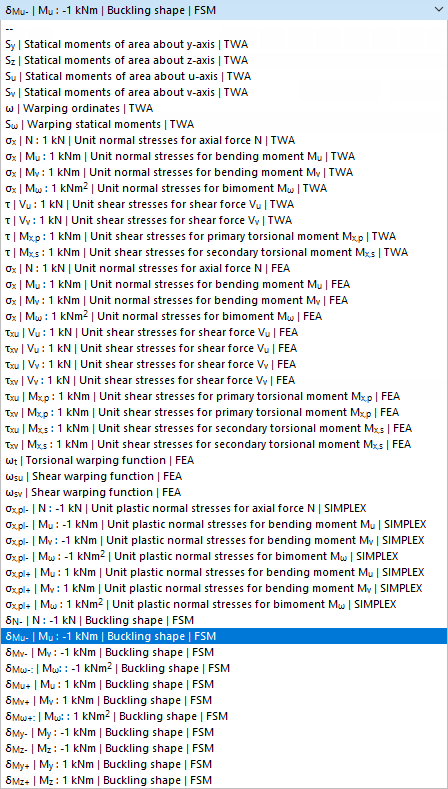

The Stress Points tab consists of up to four sub-tabs. There you can view the coordinates of the stress points, the statical moments and warping coordinates with the associated thicknesses (for thin-walled cross-sections), as well as the unit stresses calculated with the thin-walled analysis TWA (for thin-walled cross-sections) and with the finite element method FEM.

You can check the cross-section distribution and stress curves in the cross-section graphic: Click in the column of the value or select the type from the list below the graphic.

FE Mesh

The last tab manages the settings for the FE mesh, on the basis of which the cross-section values and unit stresses are determined.

The two text boxes allow you to influence the discretization. With a factor smaller than 1, a finer mesh is generated; with a factor greater than 1, a coarser mesh is generated. Generally, no adjustments are required here.