The design rules according to EC5 are explained for the timber panel wall already presented in the article Design of Timber Panel Wall with Beam Panel Thickness Type. Material and geometry properties are taken from this article and are therefore not determined here again.

The timber panel wall has one-side sheathing. The design is carried out for the horizontal deflection of 12 kN in Load Combination 1.

The plate width is applied with a length of 2.56 m. Usually, no large-format plates are used. For normal plates, the width would have to be set to 1.25 m!

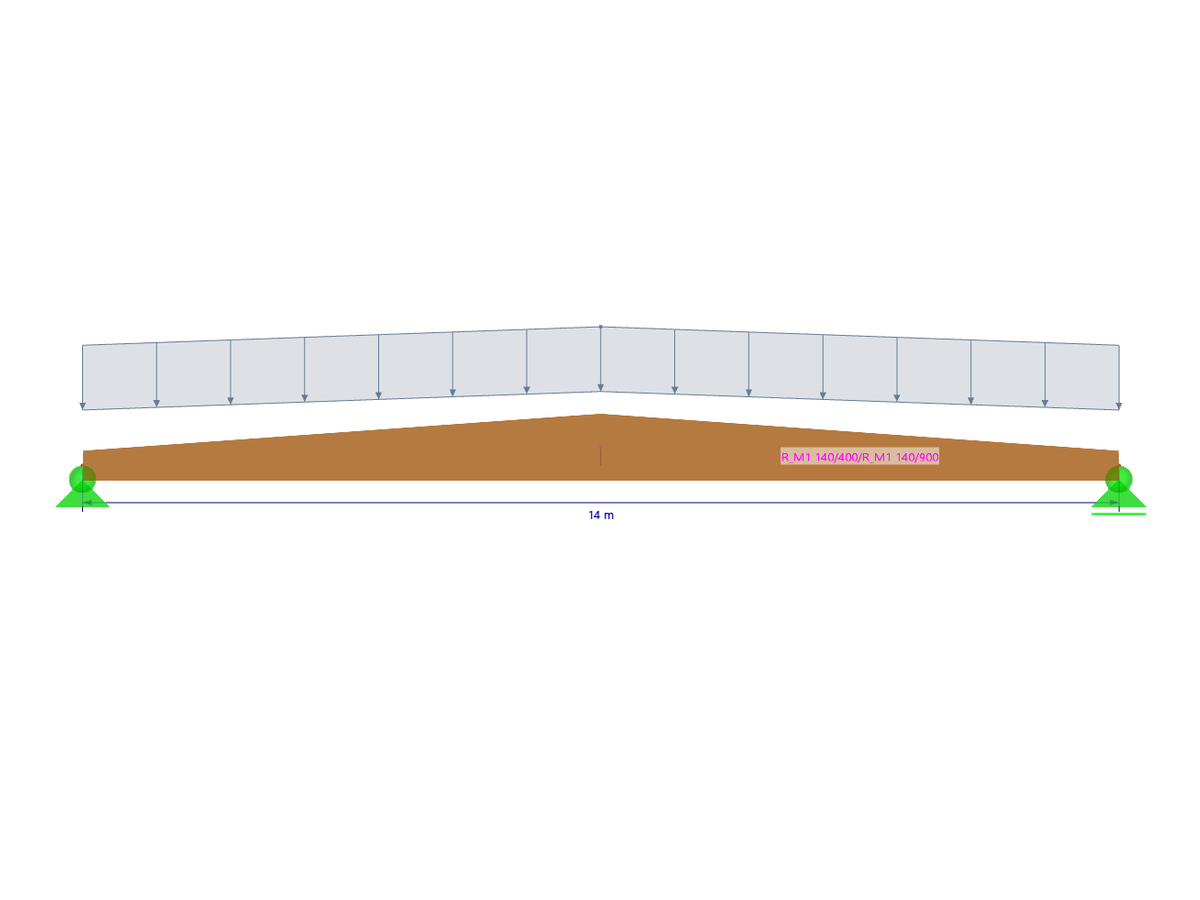

The vertical loads are introduced by the 3D model at the upper frame. Due to the continuity effect, the resulting axial force of 6.75 kN/m × 0.625 m = 4.22 kN determined in the manual calculation does not result.

In the calculation with the Beam Panel thickness type, the maximum axial force of -4.72 kN results from a purely vertical load of 6.75 kN/m. The image shows axial forces with the continuity effects and without them.

Together with the horizontal force, the load combination results in a compressive force of -12.66 kN.

Ribs are considered as laterally restrained against rotation and buckling. The design according to 6.3.2 of [1] is therefore performed about the major axis.

Design of Supports

Inclinations (imperfections) and wind loads will be discussed in a future article on spatial calculation.

Design of Sheathing

In the sheathing design, there are three failure modes to be analyzed.

- Design of Fasteners

- Shear resistance of the OSB/3 board

- Buckling of the sheathing

Design of Fasteners

Buckling resistance (according to 8.30 [1])

The tensile strength is assumed to be fu,k = 900 N/mm².

Hole bearing strength of the OSB board (8.22 [1])

Buckling resistance (NA.116 [1])

- Factor A = 0.8 from Table NA.13[1]

Load capacity of the plate (9.21 [1])

- Shear wall width bi = 256 cm

- Factor ci = 1 (9.21 [1])

- Fastener distance s = 7.5 cm

Shear Flow

This value is calculated the same way in the result diagrams using the correct smoothing.

As an alternative to the result diagrams, the forces are also displayed graphically in the forces of the line hinges. For this example, the stiffnesses are only calculated in the longitudinal direction of the line hinge. Therefore, it is sufficient to analyze the forces, as shown in the following image for n. If the stiffness in Cu,z is also taken into account, it is also necessary to analyze the force vz here.

Design of fasteners:

Shear Buckling of Plate (According to 9.2.4.2[1])

- bnet = 565 mm (clear distance of ribs)

- bnet/t = 565 mm/15 mm = 37.7 less than 100

--> The buckling design is fulfilled.

Since the distance is larger than 35, the factor ksb is considered in the plate design according to German NA.

Plate Check

- Shear strength OSB fv,k = 6.8 N/mm²

- Partial safety factor yM = 1.2

- Modification factor kmod = 1.0

- Shear for the slab ksb = 35 * t/br = 0.84

- Factor according to NCI 9.2.4.2 kda = 1.0 (due to the sheathing on one side)

- Distance of ribs br = 62.5 cm

.png?mw=512&hash=4a84cbc5b1eacf1afb4217e8e43c5cb50ed8d827)