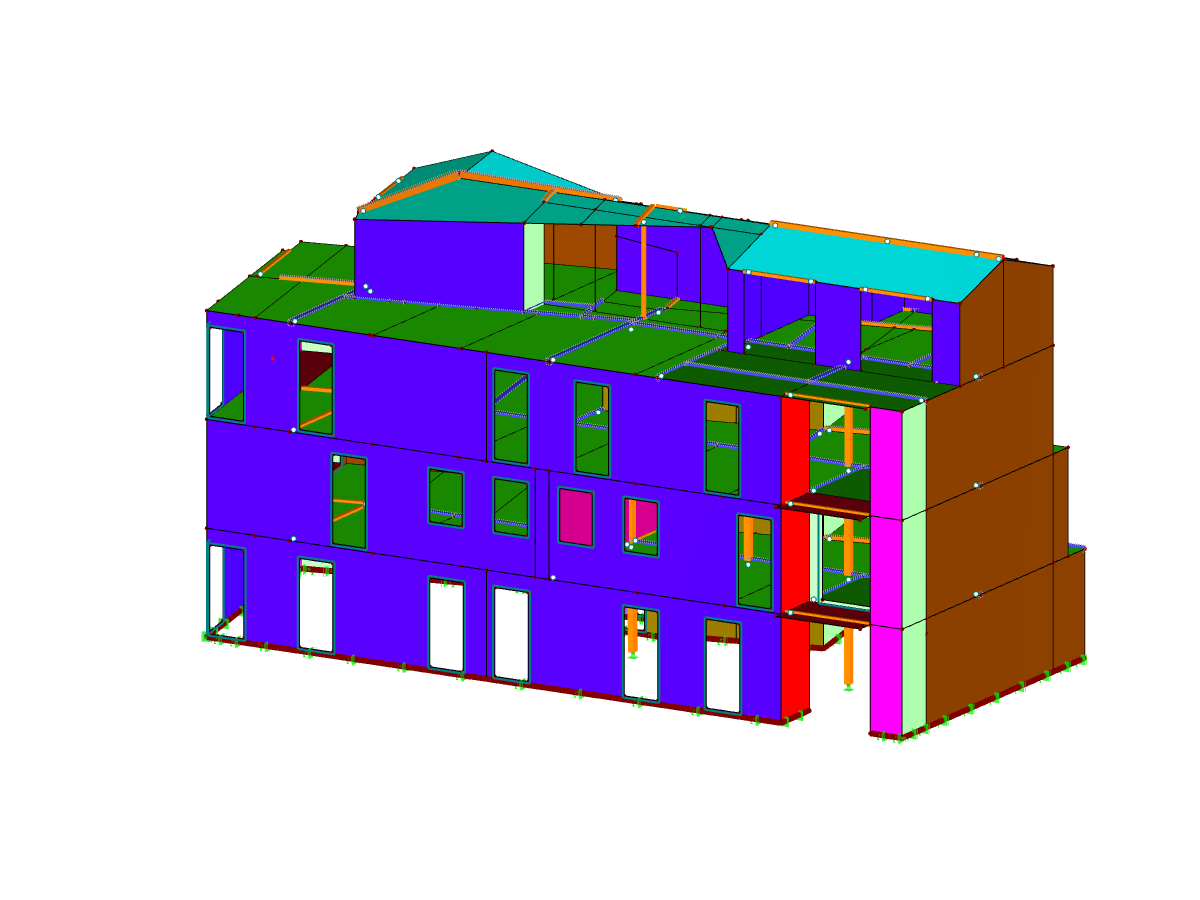

The Construction Stages Analysis (CSA) add-on allows for the design of member, surface, and solid structures in RFEM 6 considering the specific construction stages associated with the construction process. This video shows you how to define the construction stages on the model side.

KB 001737 | Defining Construction Stages in Terms of Modeling

.png?mw=512&hash=4a84cbc5b1eacf1afb4217e8e43c5cb50ed8d827)

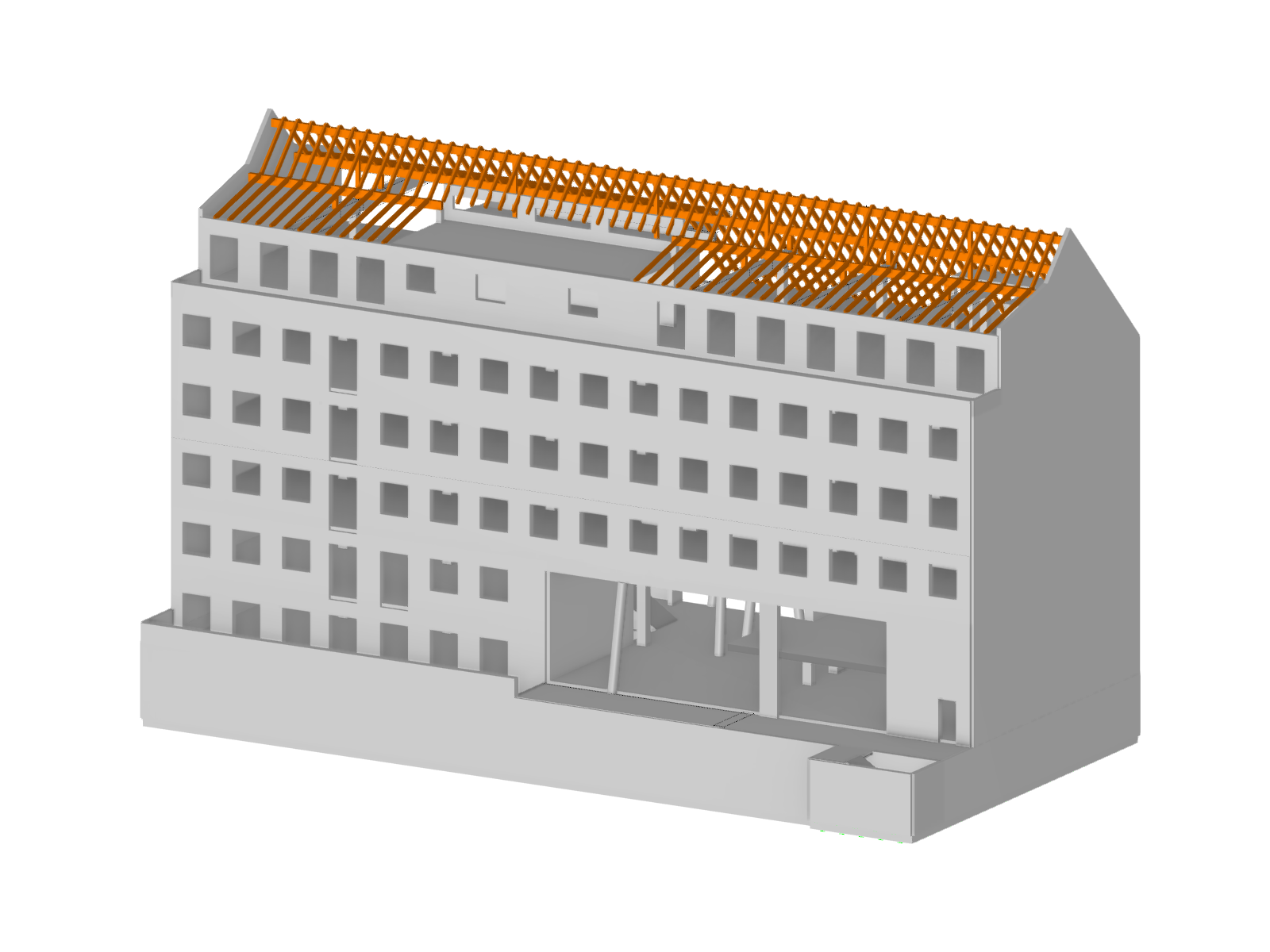

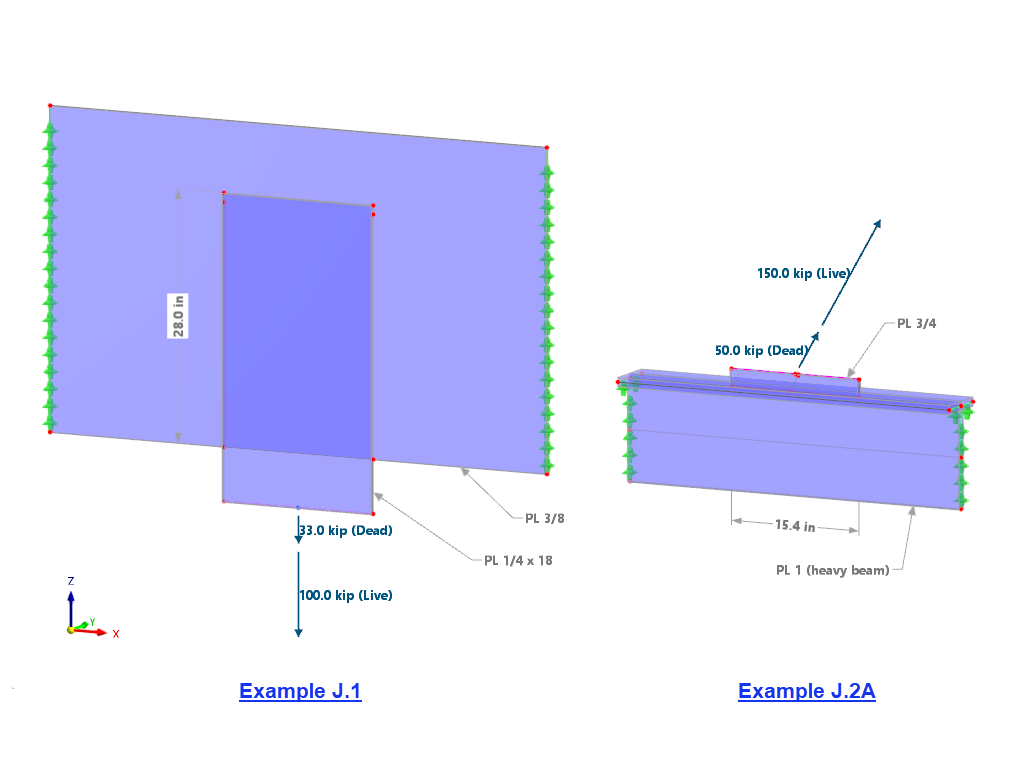

In RFEM 6, it is possible to define line welds between surfaces and to calculate the weld stresses by using the Stress-Strain Analysis add-on.

The following joint types are available:

- Butt Joint

- Corner Joint

- Lap Joint

- Tee Joint

Depending on the selected joint type, you can select the following weld types:

- Single Square

- Double Square

- Double Bevel

- Single V

- Double V

- Single U

- Double U

- Single J

- Double J

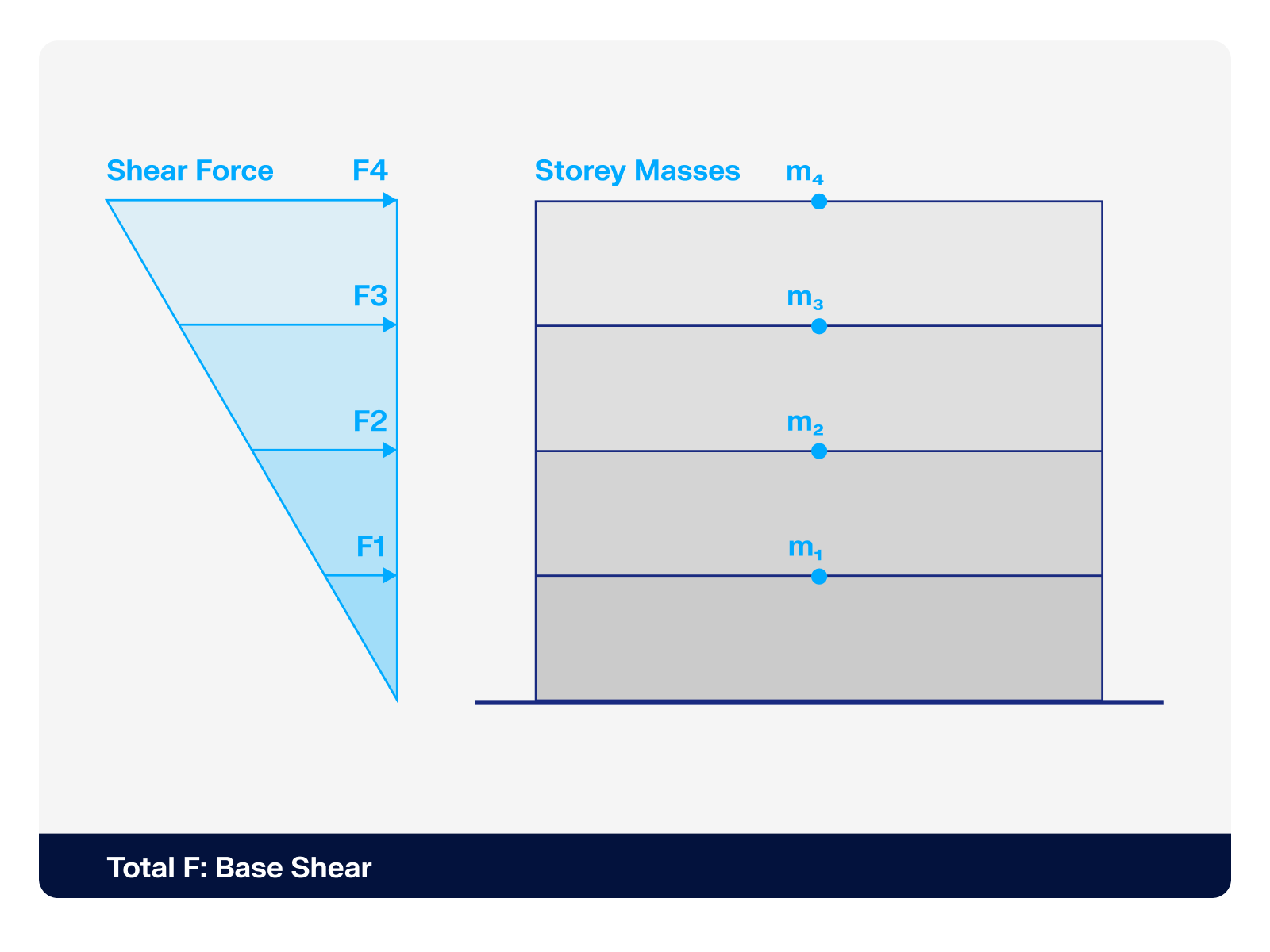

Did you use the eigenvalue solver of the add-on to determine the critical load factor for the stability analysis? Verz well, you can then display the governing mode shape of the object to be designed as a result. The eigenvalue solver is available for the lateral-torsional buckling analysis, depending on the design standard used. You can also use the internal eigenvalue solver for the general method according to EN 1993‑1‑1, 6.3.4.

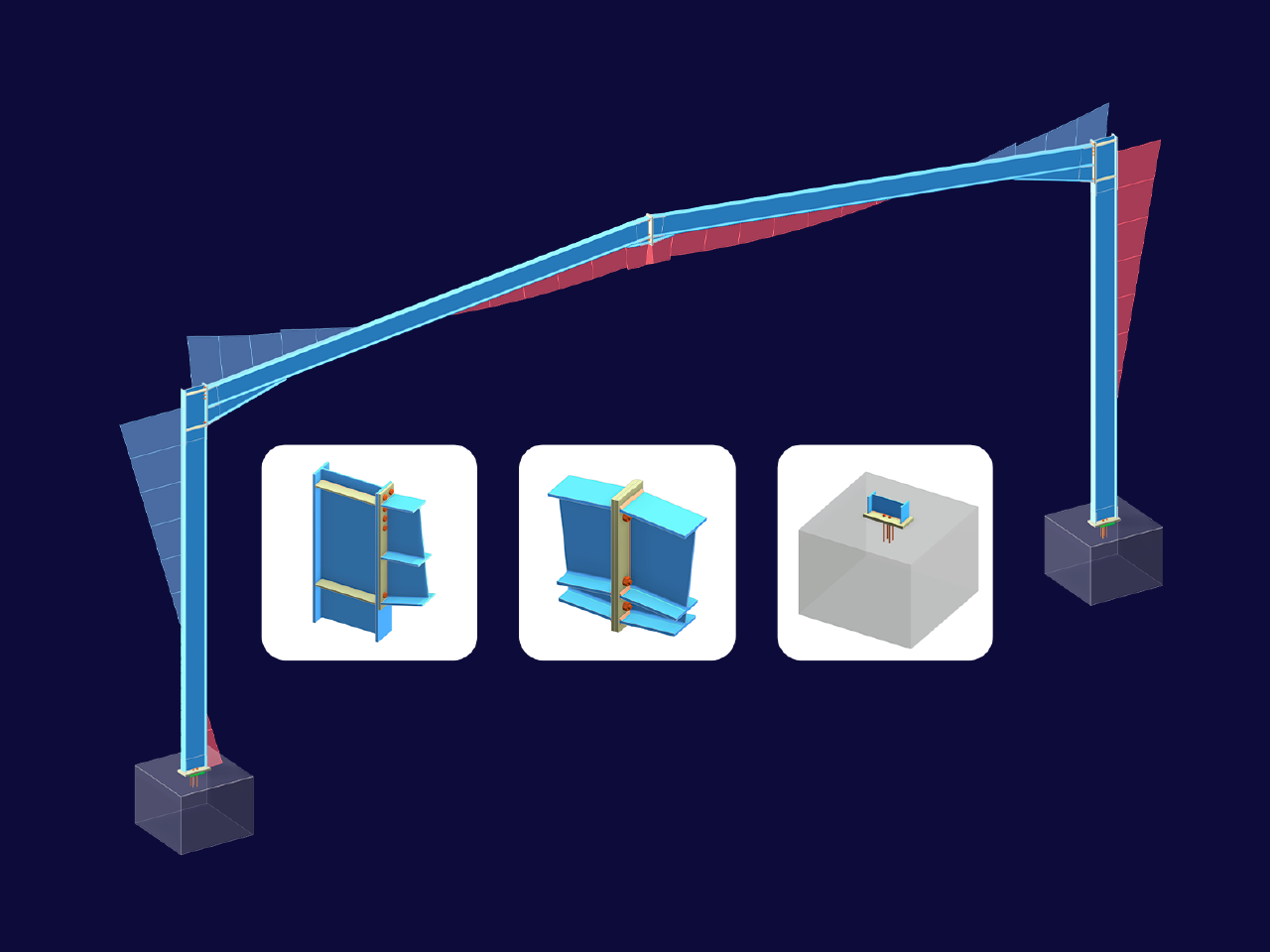

Do you want to perform a stability analysis in the Steel Design add-on? Then it is absolutely necessary to define the effective lengths. To do this, define the nodal supports and effective length factors in the input dialog box. For easy documentation and a comprehensible check of the entries, you can also graphically display the nodal supports and the resulting segments with the corresponding effective length factor in the work window of RFEM/RSTAB.

The Steel Design add-on helps you, among other things, to design general cross-sections that are not predefined in the cross-section library. To do this, create a cross-section in the RSECTION program and then import it into RFEM/RSTAB. Depending on the design standard that you have used, you can select from various design formats. One of them is, for example, the equivalent stress analysis. Do you have a license for RSECTION and Effective Cross-Sections? Then you can also perform the design checks that take into account the effective cross-section properties according to EN 1993‑1‑5.

In the Steel Joints add-on, I get high utilization ratios for preloaded bolts in the tension design. Where do these high utilization ratios come from and how can I evaluate the load-bearing reserves of the bolt?

How can treating a connection as fully rigid result in an uneconomical design?

Is it possible to consider shear panels and rotational restraints in the global calculation?

I am calculating a support that is clamped at the base, held in the X direction at the head, and can buckle in the Y direction. I have set the bar shear lengths using node carriers. In the verification, the buckling length values for the calculation are the same, L_(cr,z) = L_(cr,y) = 2.41 m. What am I doing wrong?

Dlubal_KohlA_]_LI.jpg?mw=350&hash=21d94ec9a723c608496e9e95a21bb1309ab5067a)

Dlubal_KohlA_Rev1.png?mw=350&hash=f8d2ccd6ebb5a4c58d1c98f433e9f5171a41f581)

_1.jpg?mw=350&hash=ab2086621f4e50c8c8fb8f3c211a22bc246e0552)

.png?mw=600&hash=49b6a289915d28aa461360f7308b092631b1446e)