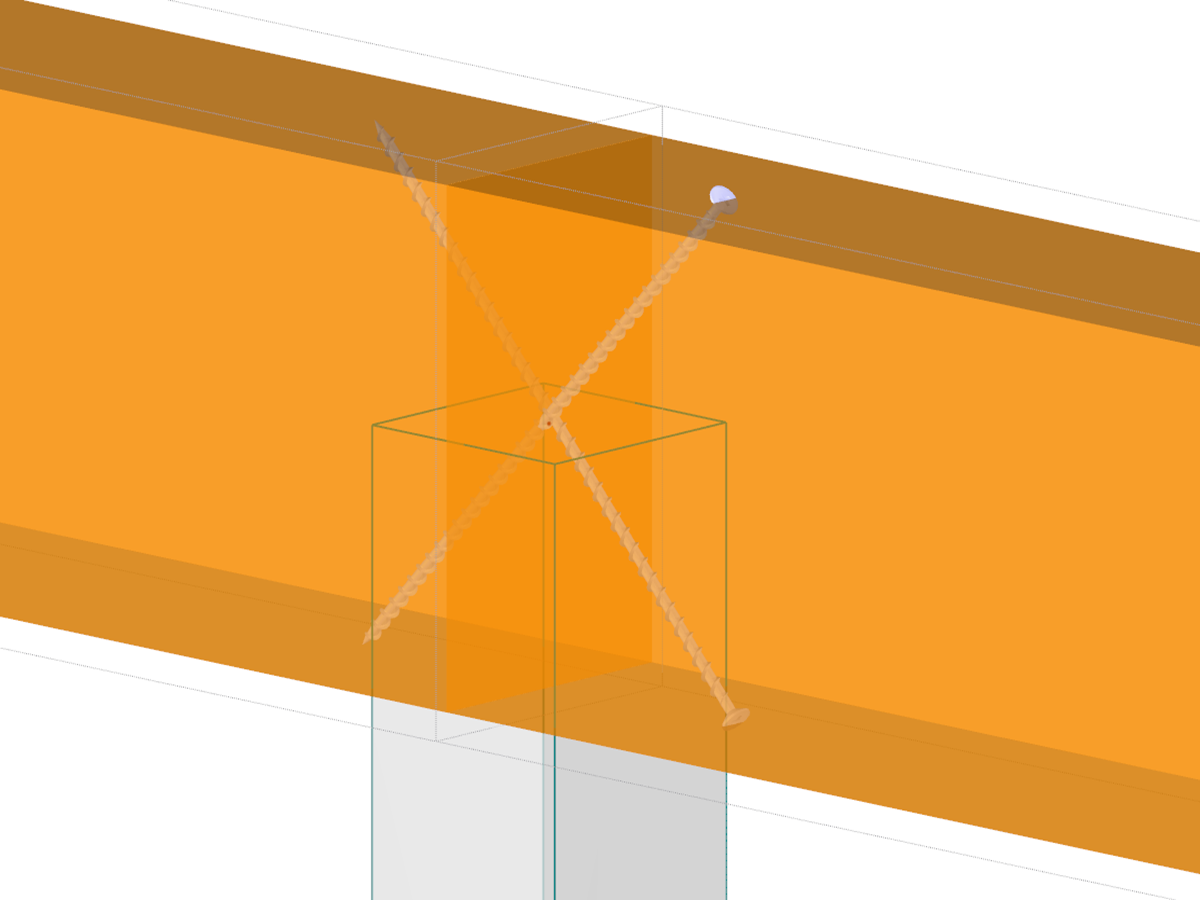

- Design of hinged connections

- Biaxial inclination of the connected member (for example, a jack rafter joint)

- Connection of any number of members on one node for the "Main member only" type

- Screw diameter 6 mm – 12 mm

- Automatic check of the minimum distance between screws

- Optional free definition of screw distances

- Transfer of eccentricity from RFEM/RSTAB

- Crosswise or parallel screw alignment

- Definition of up to 16 screws in a row

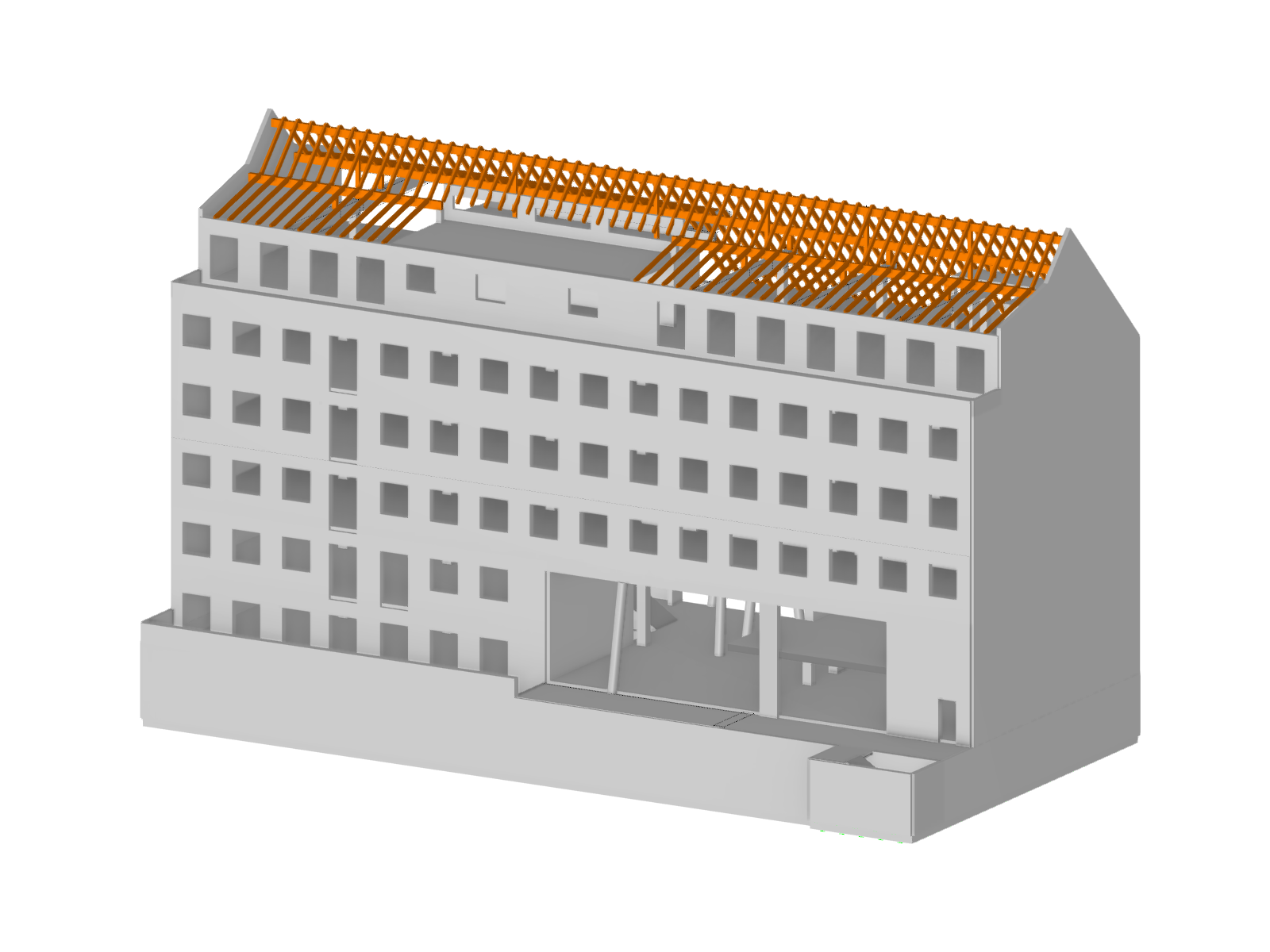

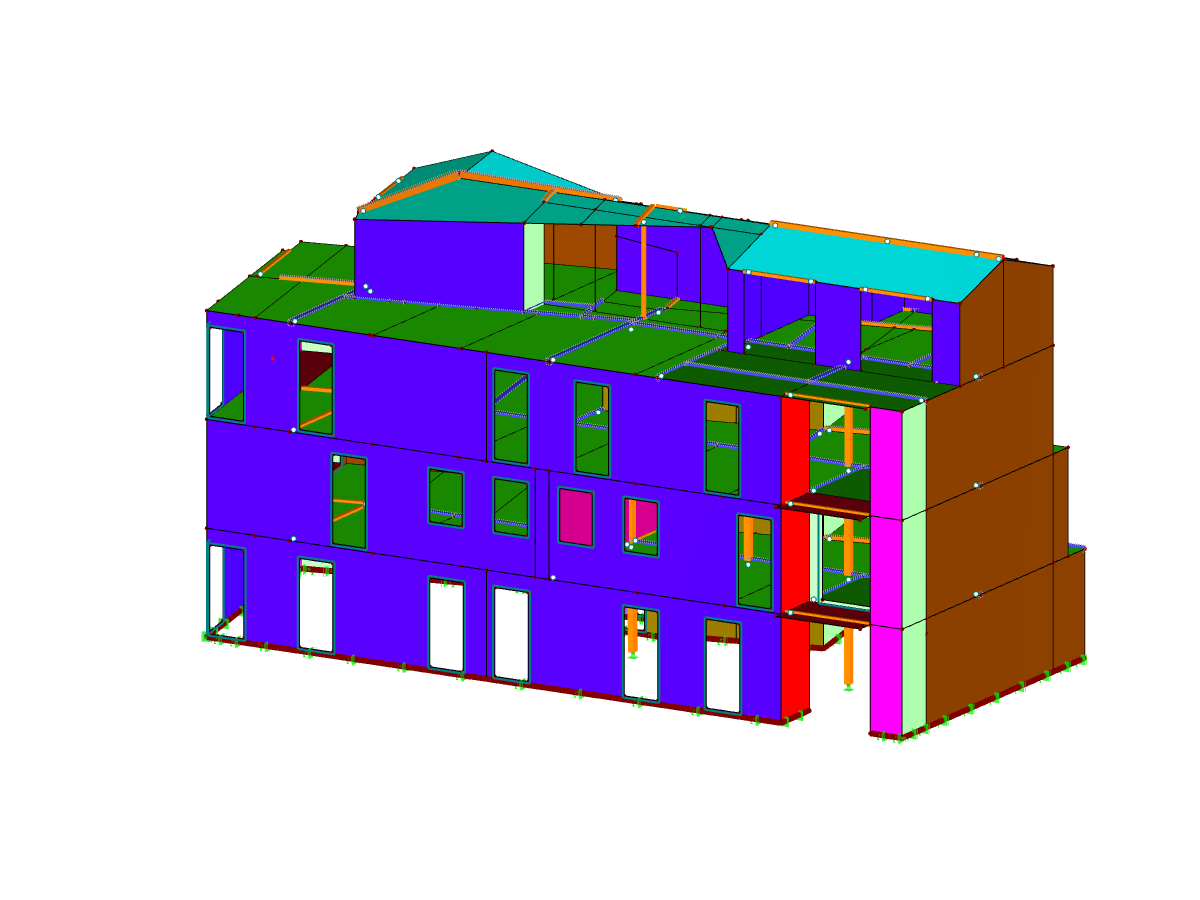

- Graphical visualization of joints in the add-on module and in RFEM/RSTAB

- Performing all required designs

RF-/JOINTS TIMBER - Timber to Timber | Features

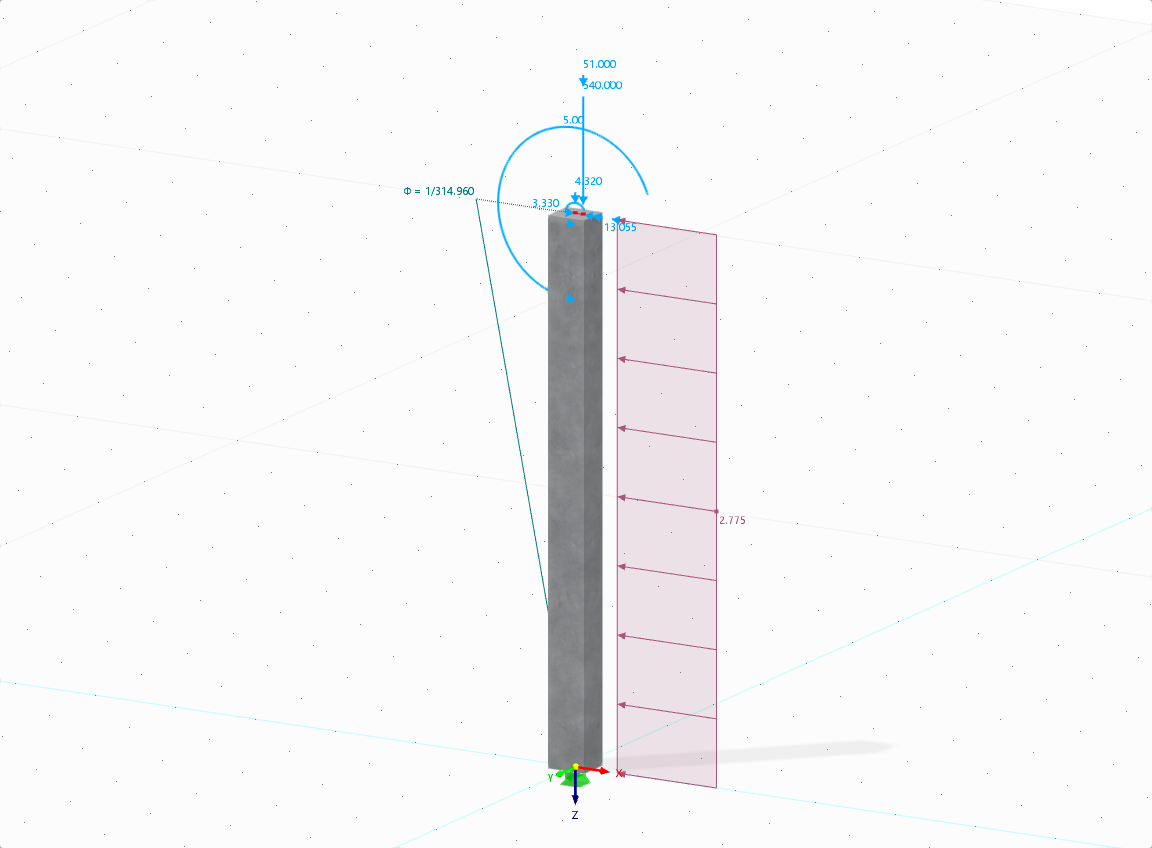

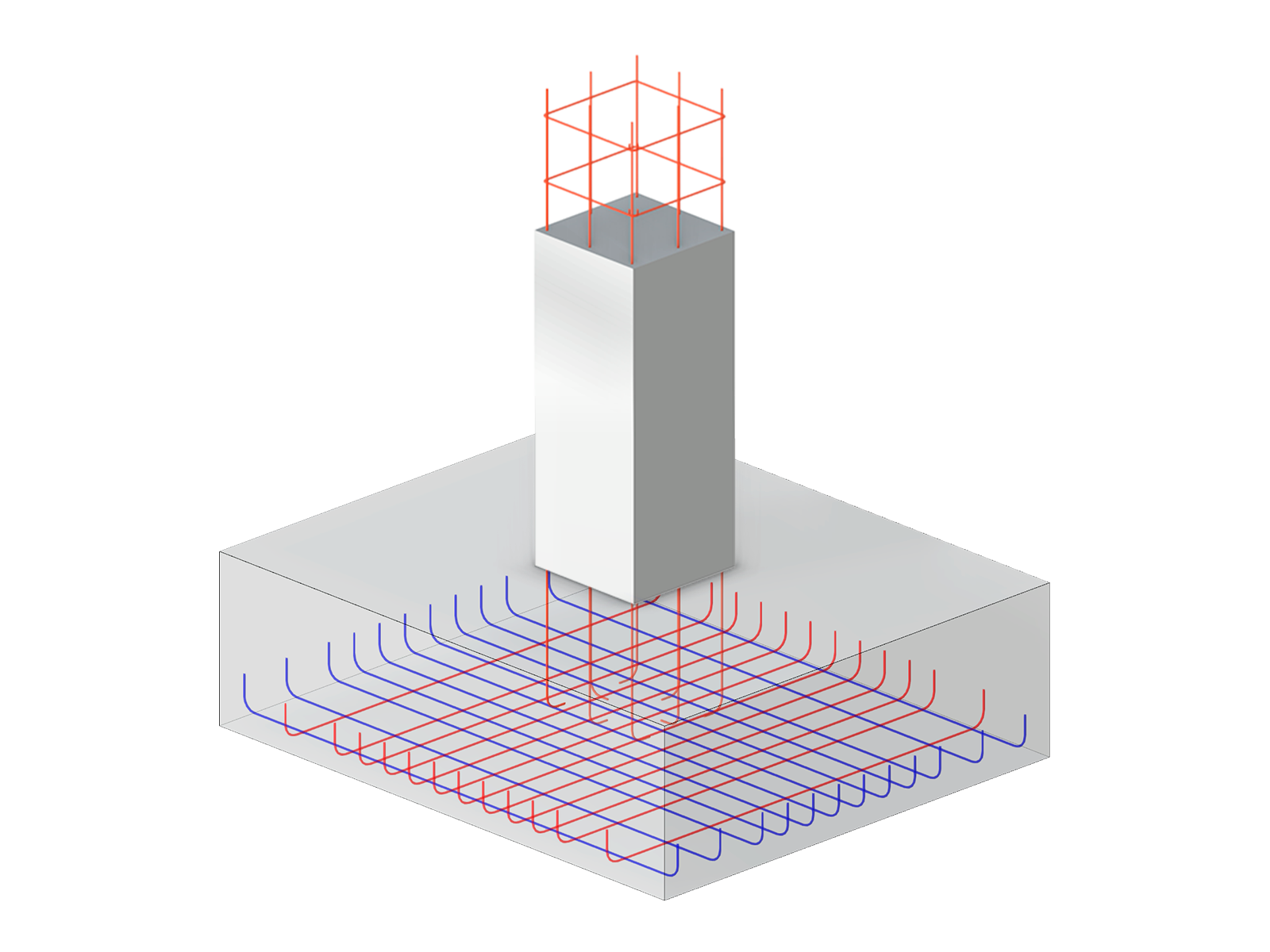

The aim of this technical article is to perform a design according to the general design method of Eurocode 2, using the example of a slender reinforced concrete column.

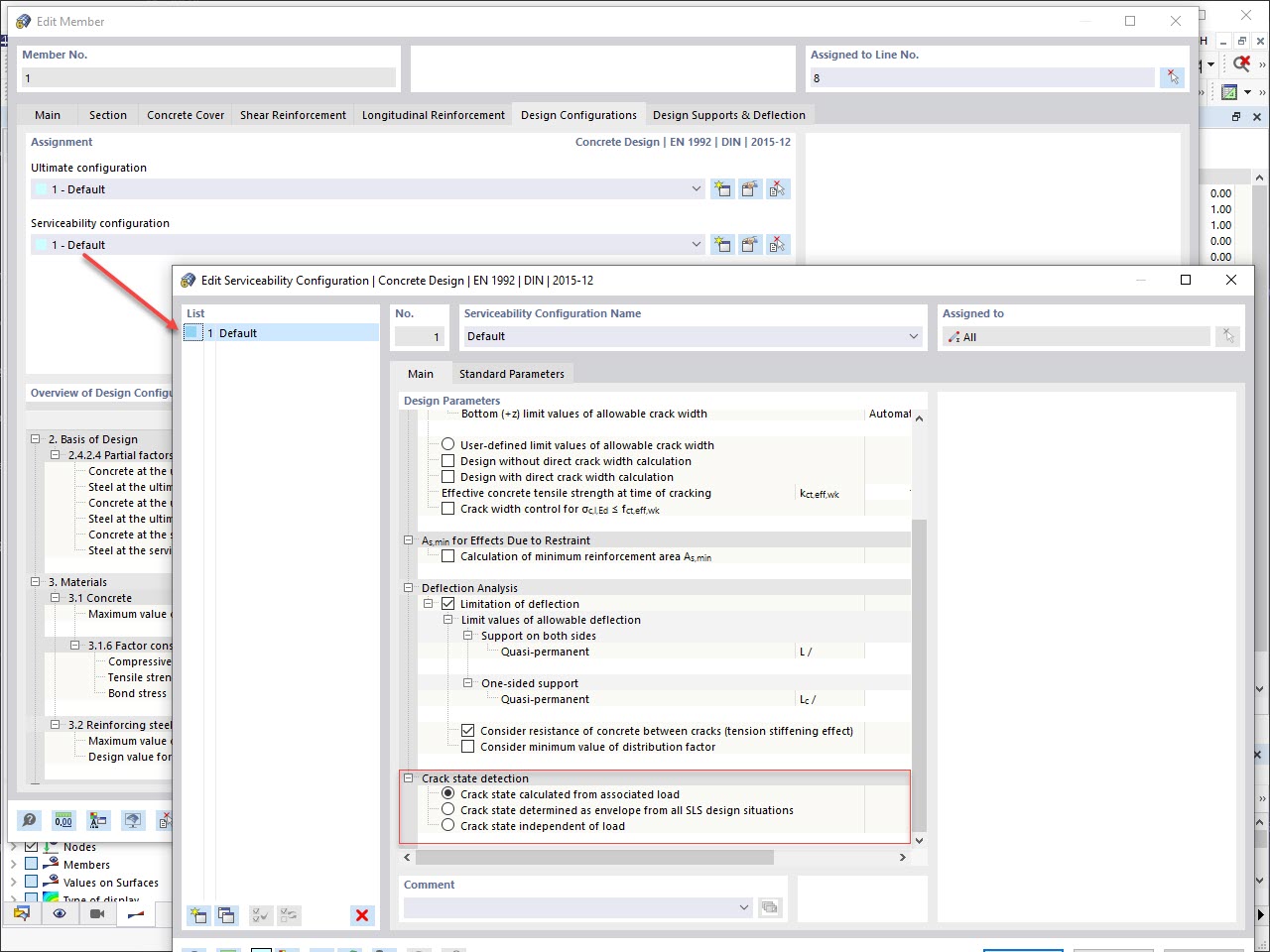

Various design parameters of the cross-sections can be adjusted in the serviceability limit state configuration. The applied cross-section condition for the deformation and crack width analysis can be controlled there.

For this, the following settings can be activated:

- Crack state calculated from associated load

- Crack state determined as an envelope from all SLS design situations

- Cracked state of cross-section - independent of load

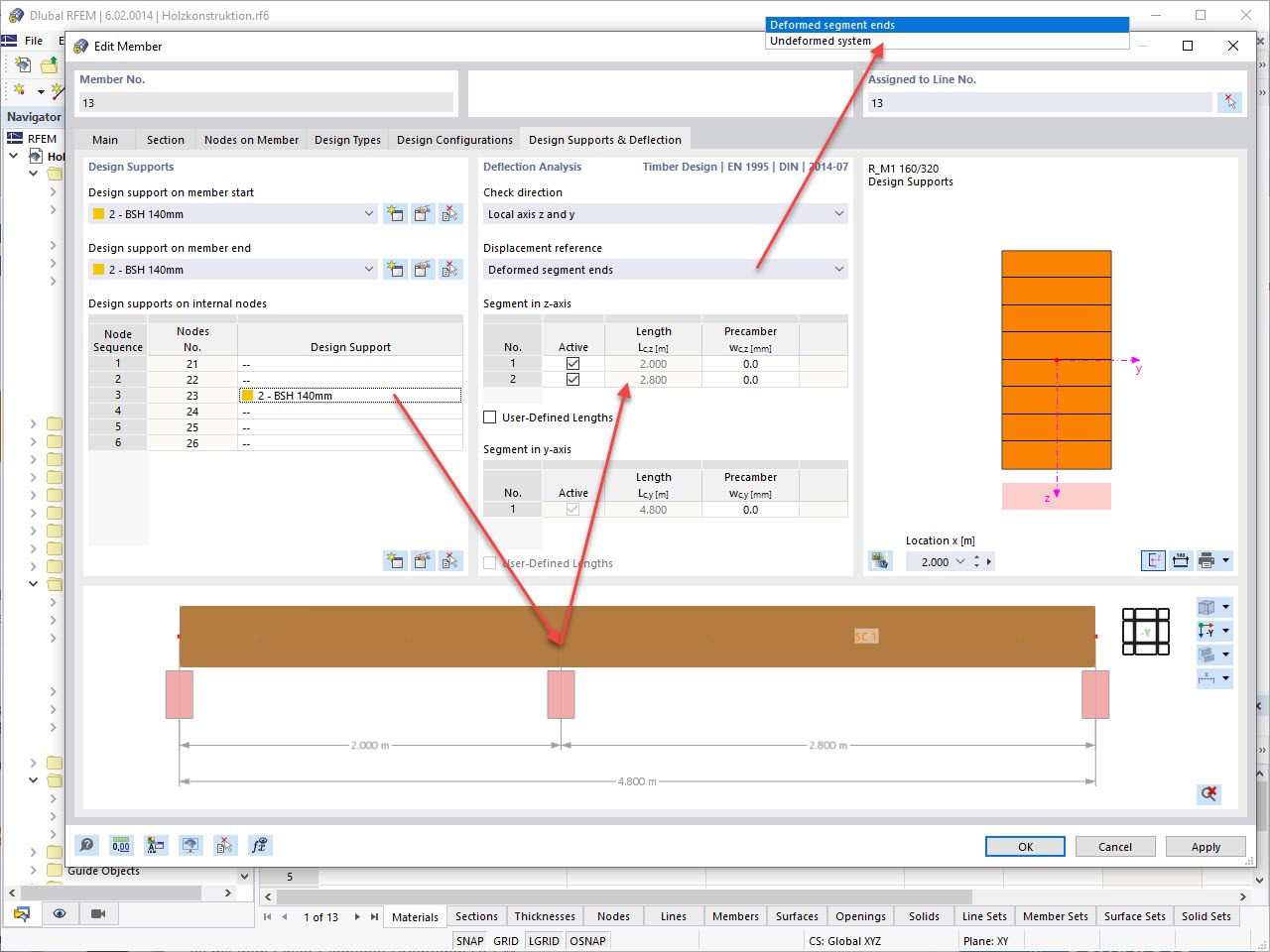

In the "Deflection and Design Support" tab under "Edit Member", the members can be clearly segmented using optimized input windows. Depending on the supports, the deformation limits for cantilever beams or single-span beams are used automatically.

By defining the design support in the corresponding direction at the member start, member end, and intermediate nodes, the program automatically recognizes the segments and segment lengths to which the allowable deformation is related. It also automatically detects whether it is a beam or a cantilever due to the defined design supports. The manual assignment, as in the previous versions (RFEM 5), is no longer necessary.

The "User-Defined Lengths" option allows you to modify the reference lengths in the table. The corresponding segment length is always used by default. If the reference length deviates from the segment length (for example, in the case of curved members), it can be adjusted.

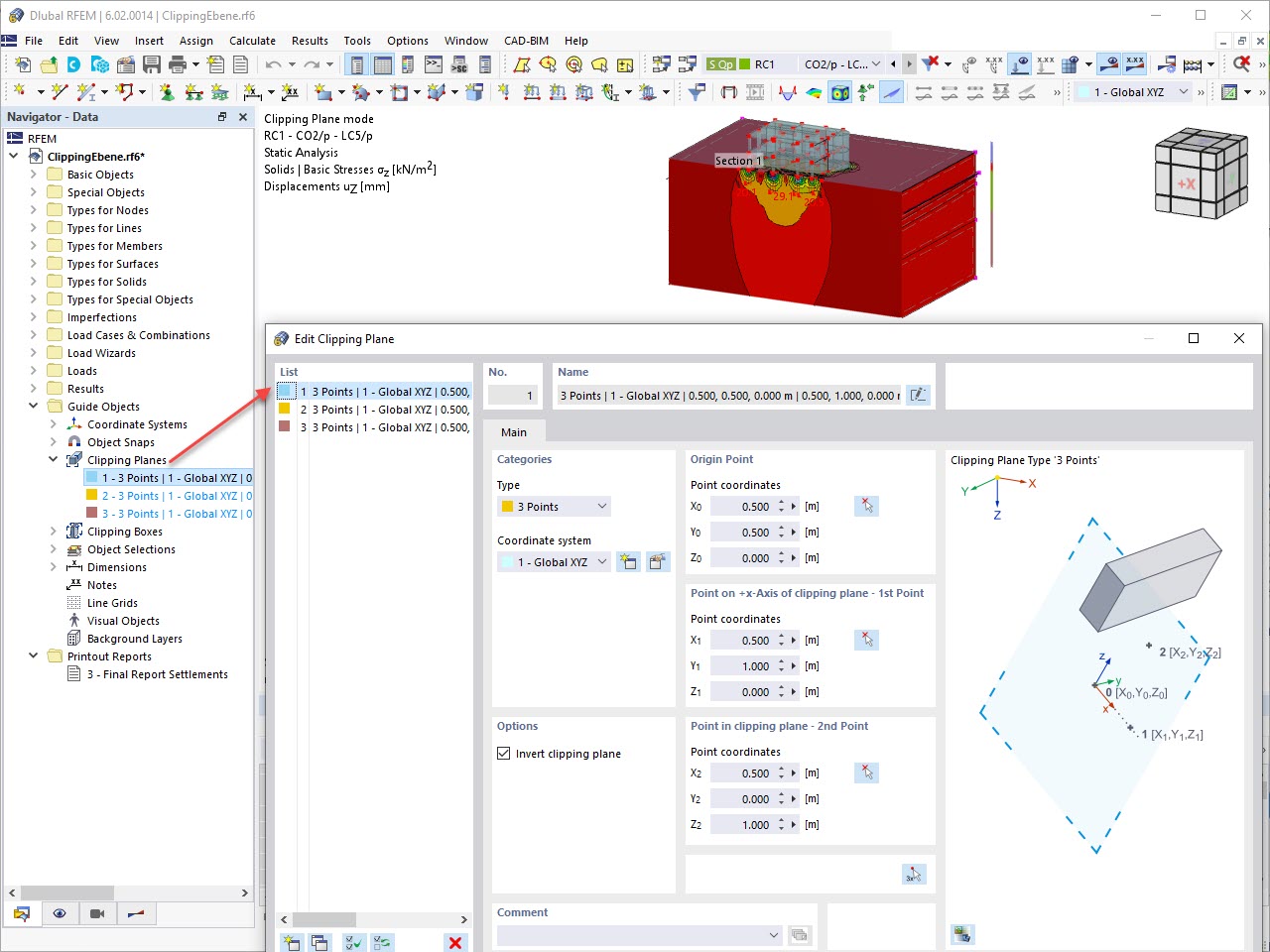

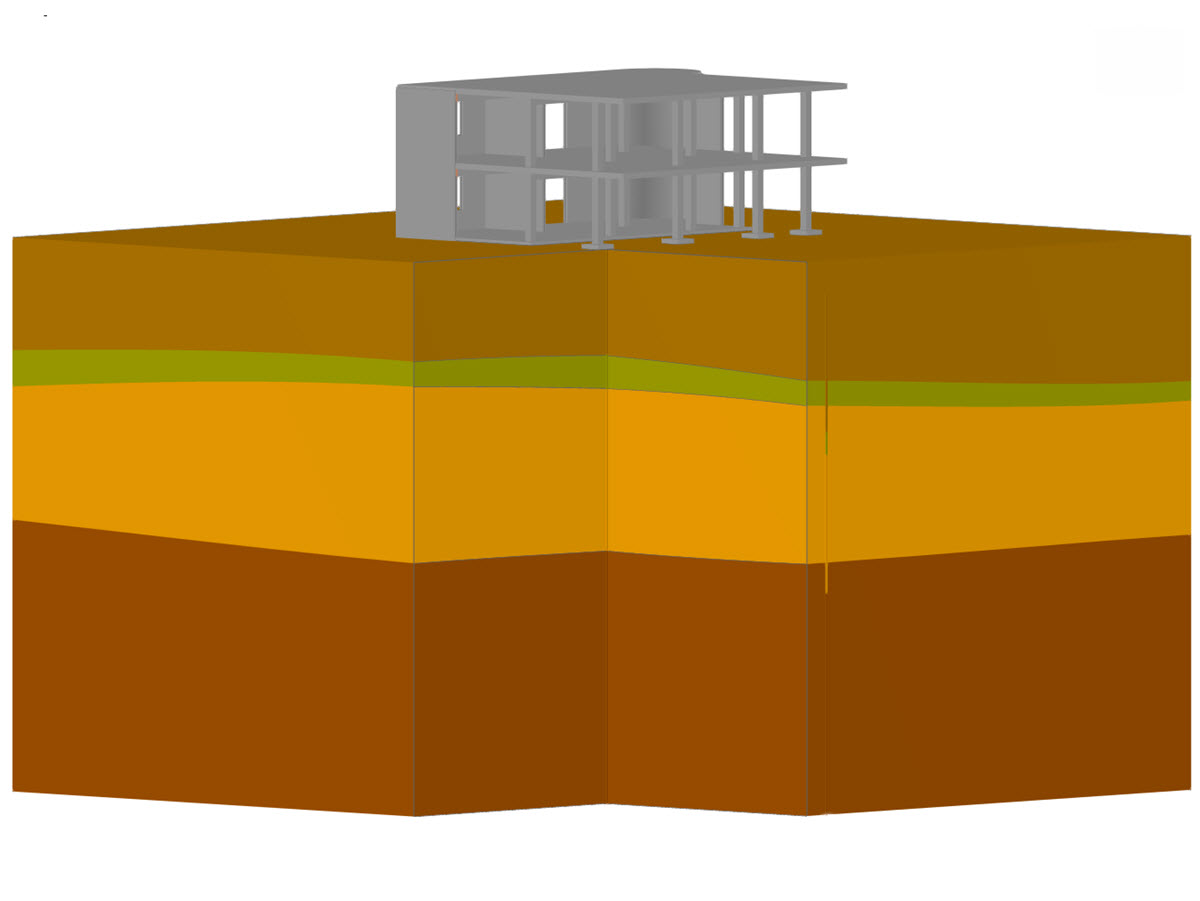

This feature also contributes to the clearly-arranged display of your results. Clipping planes are intersecting planes that you can place freely throughout the model. The zone in front of or behind the plane is consequently hidden in the display. This way, you can clearly and simply show the results in an intersection or a solid, for example.

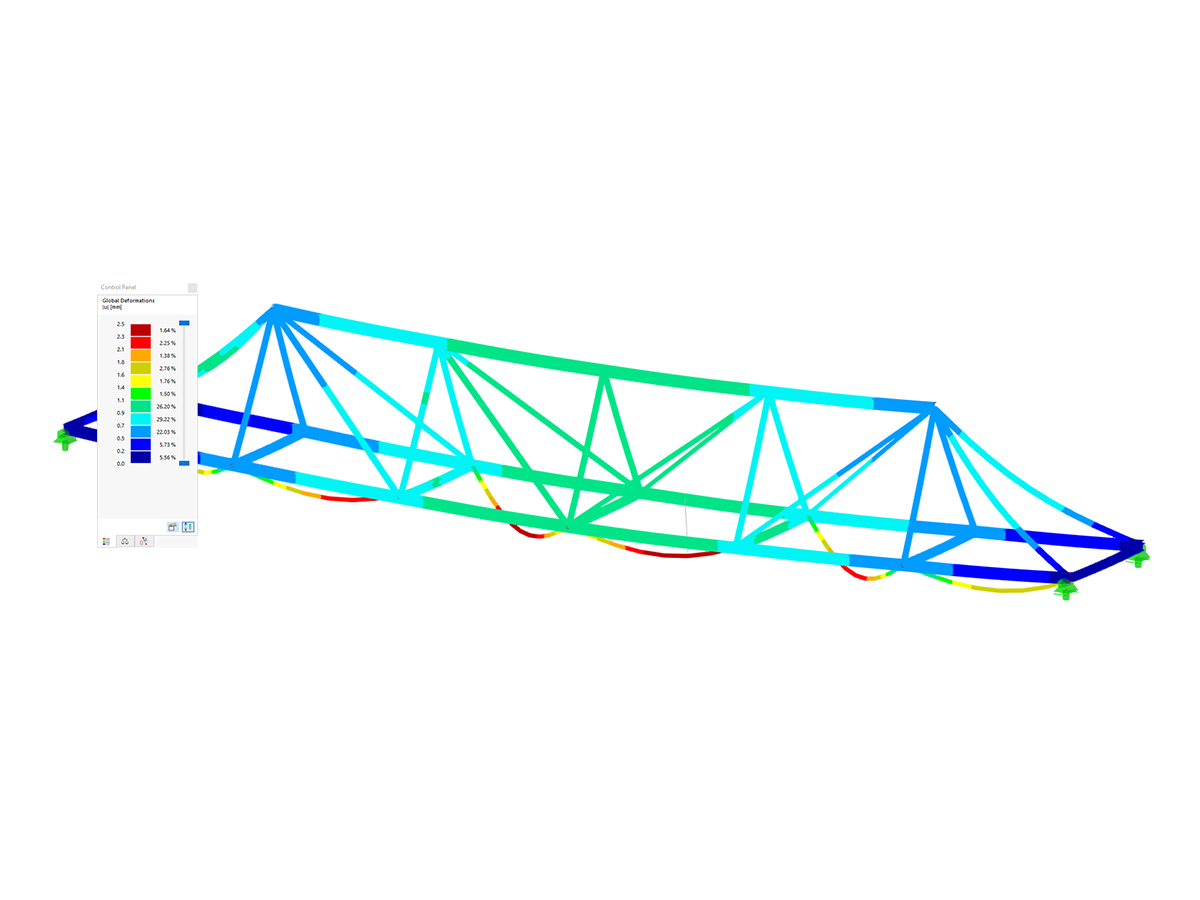

The deformation process of the global deformation components can be represented as a movement sequence.

Why is the effective depth different with the effective depth used in shear checks?

.png?mw=1024&hash=7c424b9b75f951cc6b40e414ba09ed21ca789737)

Dlubal_KohlA_]_LI.jpg?mw=350&hash=21d94ec9a723c608496e9e95a21bb1309ab5067a)

.png?mw=600&hash=49b6a289915d28aa461360f7308b092631b1446e)