Float glass is a basic glass product, and its name describes the production process. This glass type has no self-equilibrating stresses and can, therefore, also be called annealed glass. This glass is used, for example, in window construction, facade construction, interior design, and furniture construction.

Partly tempered glass and toughened safety glass are products that are manufactured by refining float glass. By subsequently heating the glass and then using a defined cooling process, products with a residual stress state are created. This process creates a parabolic prestressing profile across the cross-section, which leads to higher strengths of the glass, and greater flexural tensile stresses can be absorbed.

A distinction is made here between partial and full prestressing of the cross-section. Of course, different bending rigidities are achieved, but other properties, such as the fracture pattern, also change. Toughened safety glass has a small crumbled fracture pattern, which significantly reduces the risk of cuts. In contrast to float glass, however, partly tempered glass shows a rough fracture pattern, which may be decisive for the residual capacity of overhead glazing, for example.

Laminated Glass and Laminated Safety Glass

Laminated glass is a combination of several glass pieces that are connected by an intermediate layer. Different properties can be displayed depending on the requirements for the glass pane.

Laminated safety glass also places even greater demands on the intermediate layer. In this case, the required safety should be fulfilled in case of breakage, and thus the risk of injury should be reduced.

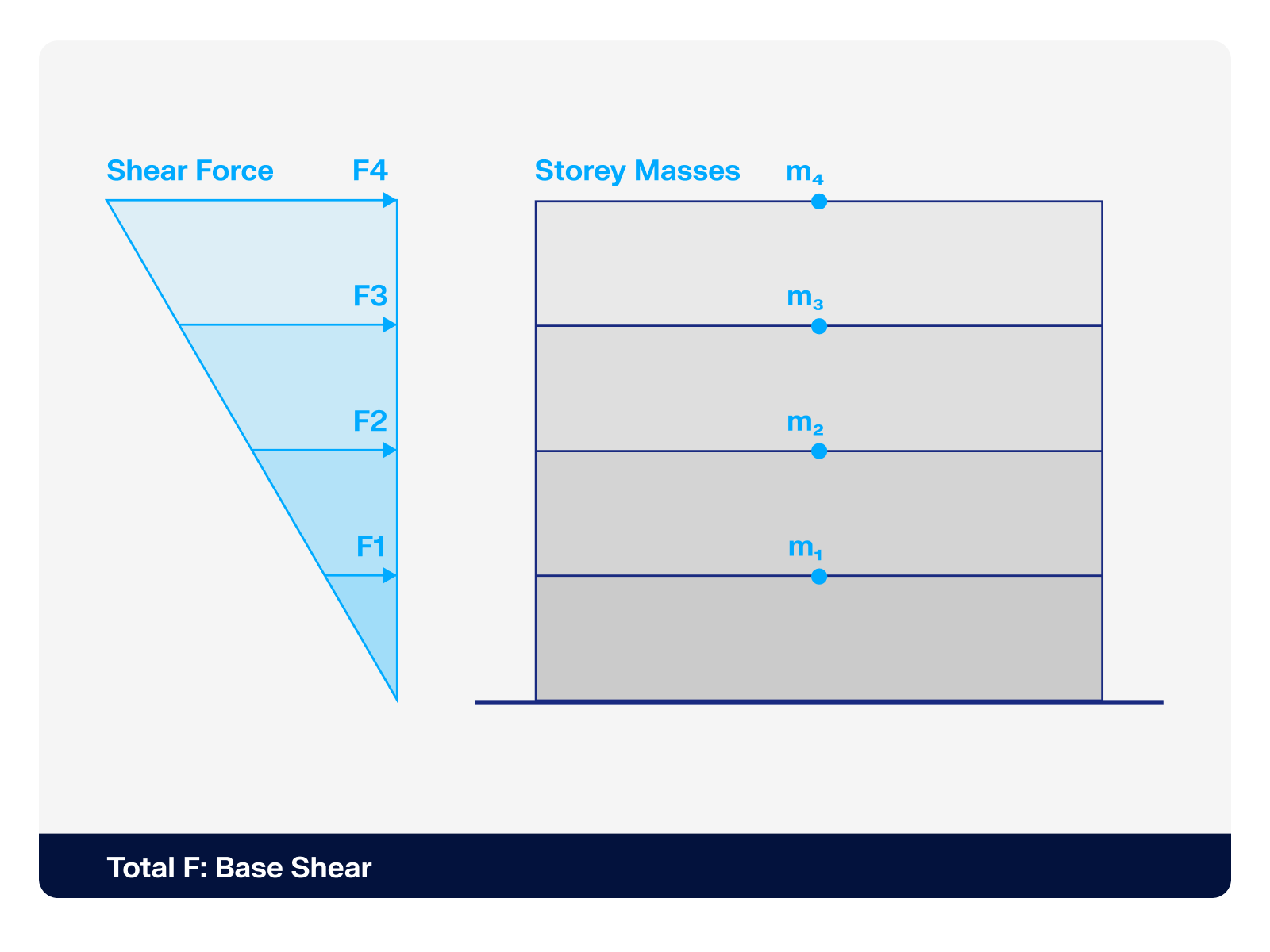

When calculating stresses and deformations, a shear coupling must not be considered according to DIN 18008‑1 if it is favorable for the structure, but must be taken into account if it results in larger stresses or deformations.

Consideration in Calculation

The simplest procedures for applying the standard for the case without shear coupling are as follows:

- Calculating a single pane with a half load

- Calculating the equivalent cross-section thickness

and the case with shear coupling:

- Calculating the double-thickness pane (rigid composite)

For computer-aided calculations, as in RFEM, more convenient solutions are available.

In RF-GLASS in particular, the layer structure can be selected via a database and constructed according to the real specifications.

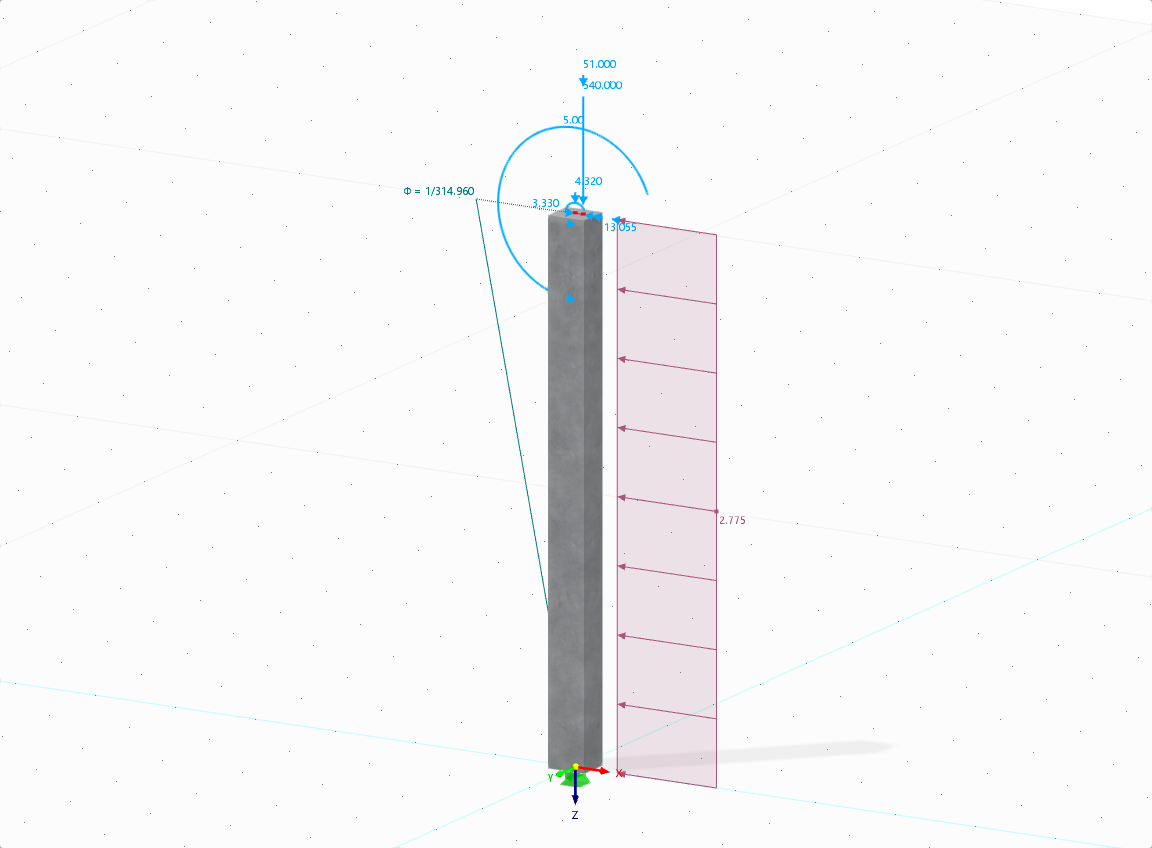

The option to consider the shear coupling between the panes can be selected in the "Details" check box. Additionally, the option of a 2D or 3D calculation is available when you activate the shear coupling. The background of these two options is that in a 2D calculation, an equivalent cross-section is automatically created and the system is calculated with the plate theory.

In the 3D calculation, solid elements are created by the individual layers, whereby the effect of the shear coupling is represented exactly on the basis of the defined stiffness. This option has the most realistic results, but also requires the most computing time.

Conclusion

The computer-assisted calculation with its available options helps to display systems that might be too complex for, or even impossible to edit by, manual calculation.

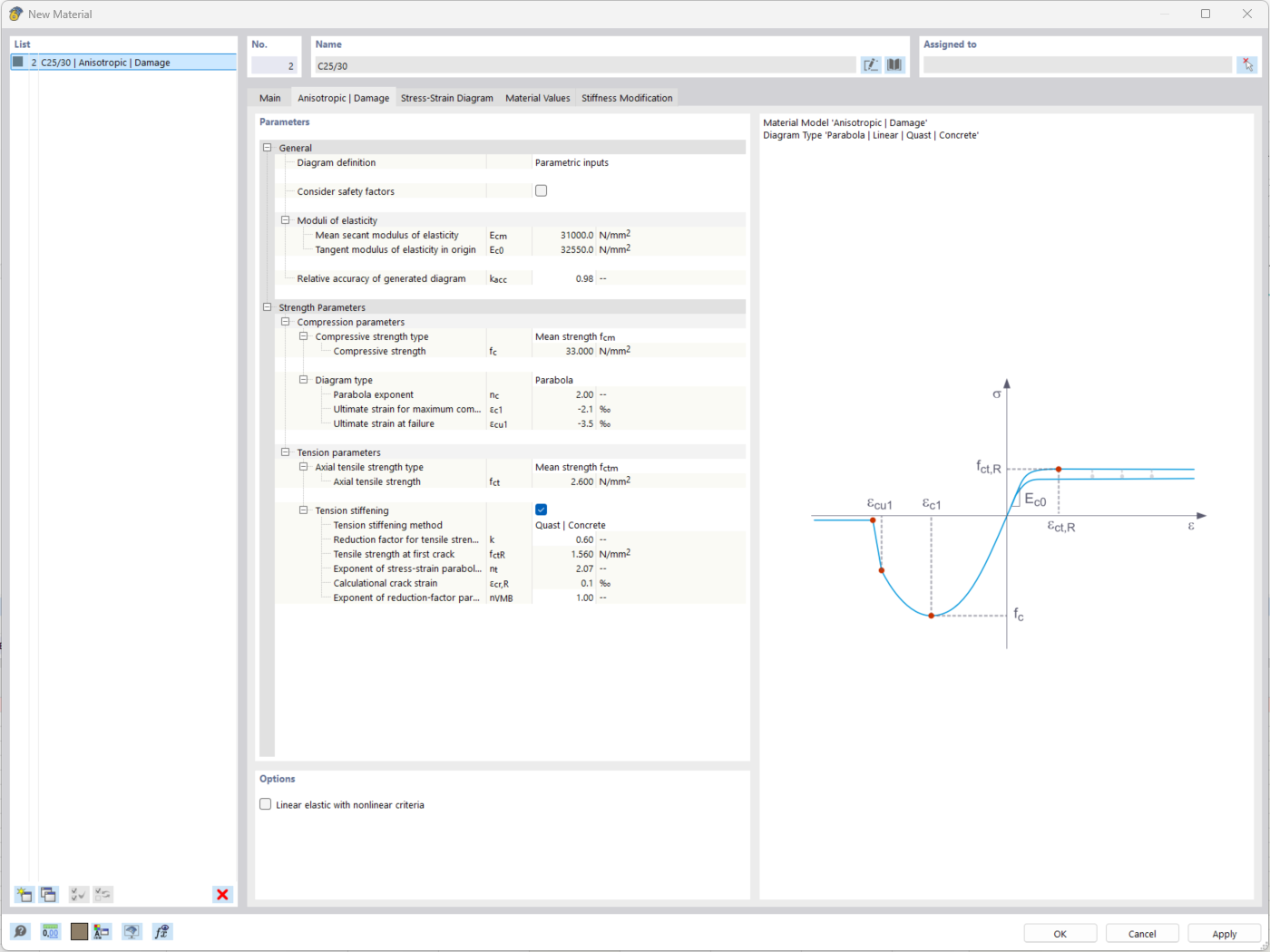

.png?mw=350&hash=c6c25b135ffd26af9cd48d77813d2ba5853f936c)

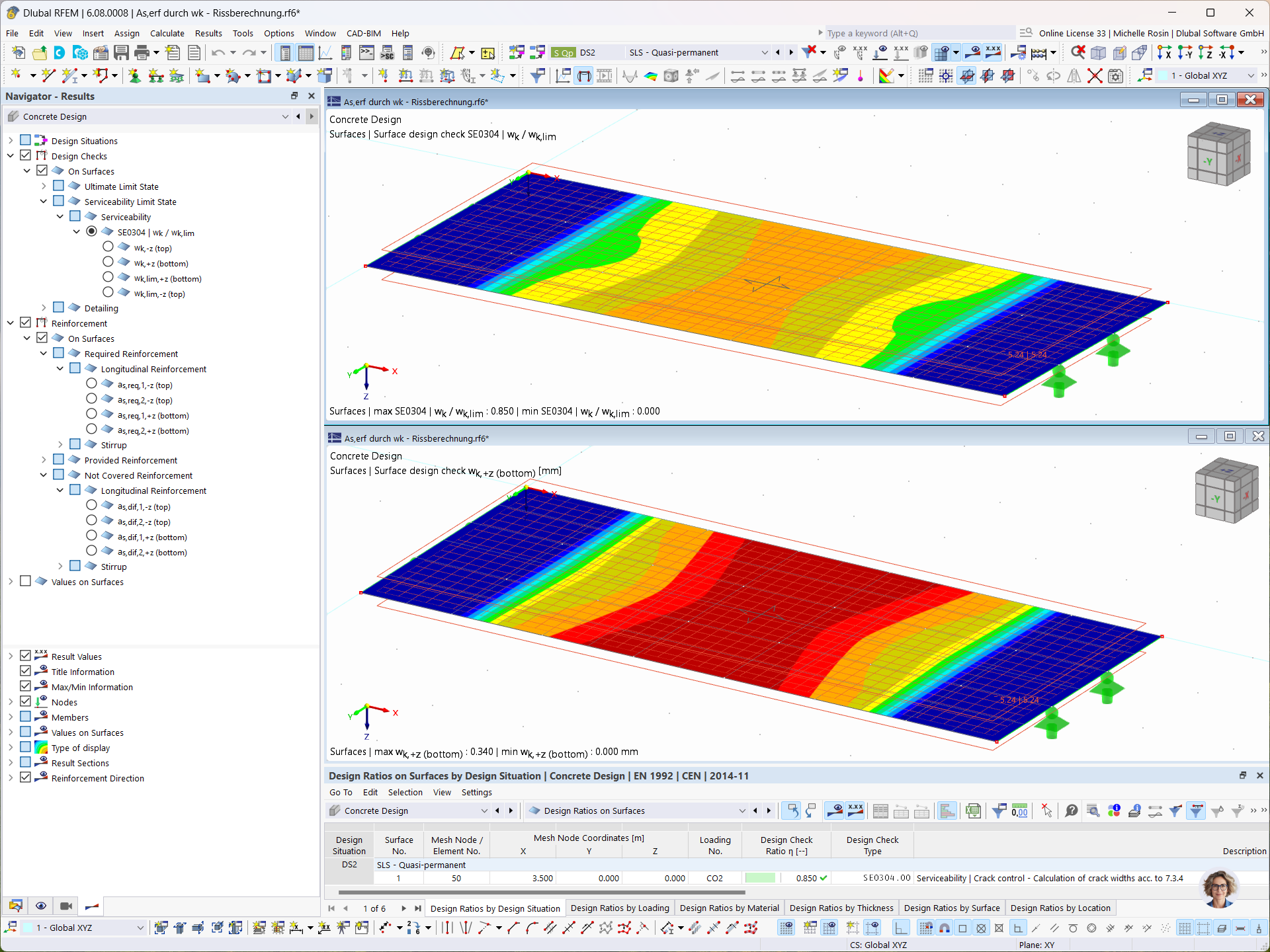

.png?mw=512&hash=4a84cbc5b1eacf1afb4217e8e43c5cb50ed8d827)

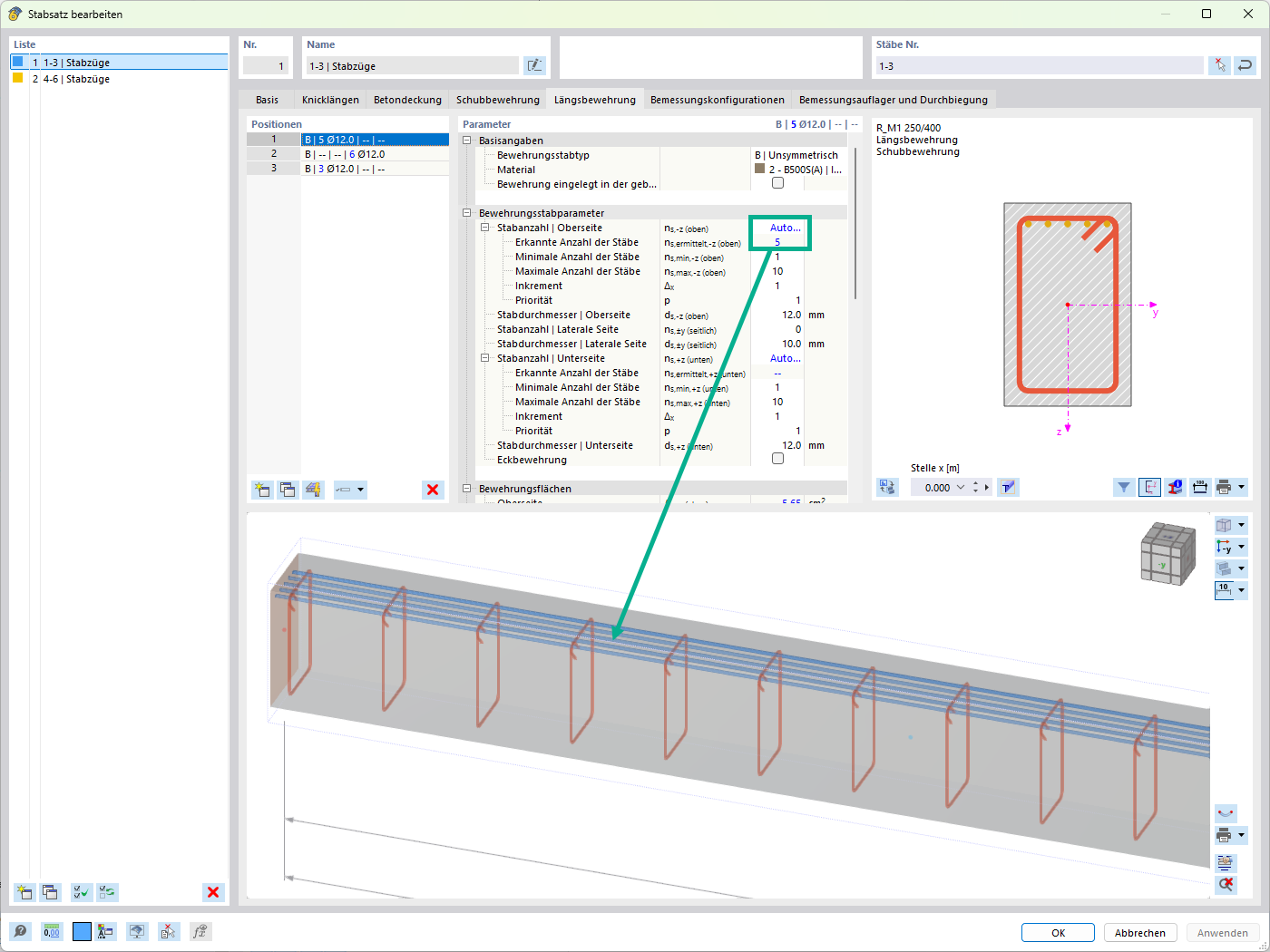

_1.jpg?mw=350&hash=ab2086621f4e50c8c8fb8f3c211a22bc246e0552)

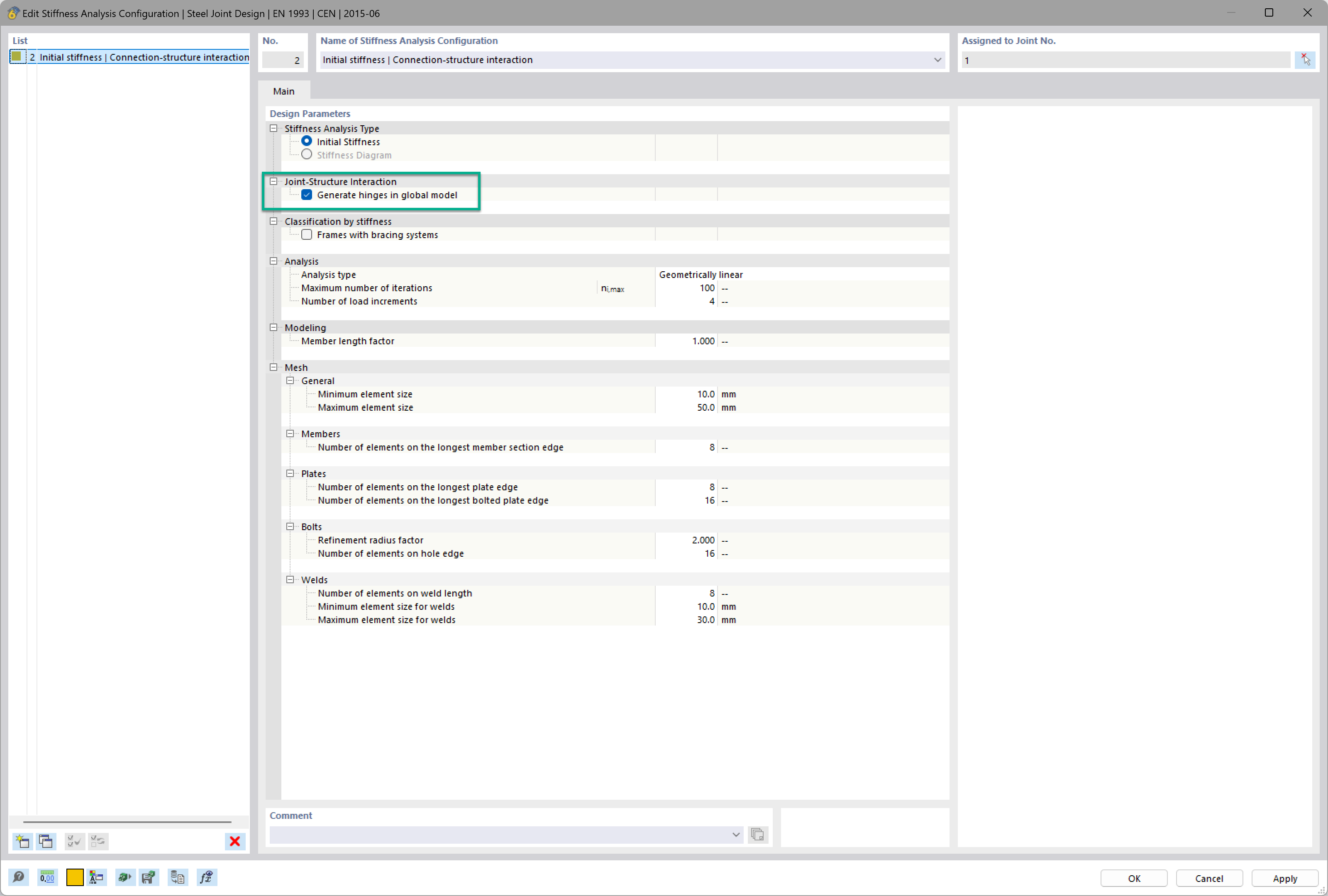

.png?mw=600&hash=49b6a289915d28aa461360f7308b092631b1446e)