A stub is a special structural component used to connect two objects; for example, to connect a beam to a column using another cross-section. This virtual member is only considered for the connection design, not in the model. The connection to the other members is carried out by welds and fasteners.

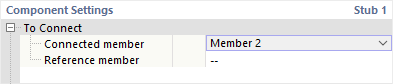

To Connect

The first category of the component settings manages the details of the members.

Specify which of the members connected to the node is relevant for the stub as the 'Connected Member'. This is usually a beam. The "Reference member" is optional. However, this is useful if a beam is connected at an angle: The slope angle is then automatically applied to chamfer the stub.

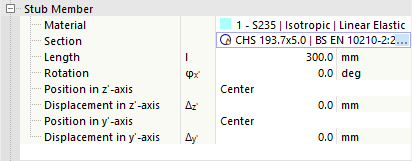

Stub Member

In this category, you can define the properties of the stub member. Select the relevant material from the defined materials or define a new material using the

![]() button. Then, define the cross-section. You can also use the button here

button. Then, define the cross-section. You can also use the button here

![]() in the text box to select the cross-section from the library of RFEM.

in the text box to select the cross-section from the library of RFEM.

In the text box of the 'Length', enter the length of the stub. If you want the member arrangement to be rotated or staggered, define the 'Rotation' or define the 'Position' using the selection lists and displacement vectors. In the graphics area, you can switch to the symbol display using the

![]() switch to the symbol view, where the parameters are illustrated.

switch to the symbol view, where the parameters are illustrated.

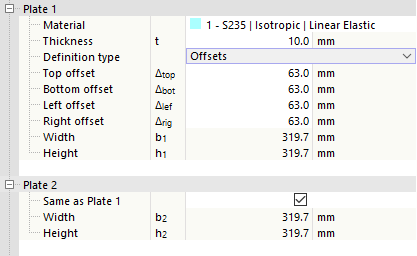

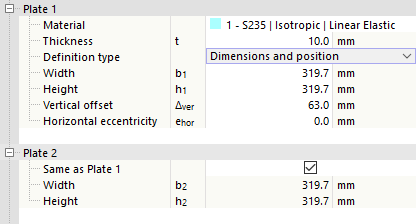

Plate 1/Plate 2

The connection of the two sections can be established by means of the plates in the transition zone between the connected member and the stub. 'Plate 1' is arranged on the connected member, 'Plate 2' on the stub.

Select the relevant material from the defined materials or define a new material using the

![]() button. Then, specify the thickness of the sheet.

button. Then, specify the thickness of the sheet.

You can define the plate geometry by 'Offsets' or 'Dimensions and Position'. Select the corresponding option in the list.

Offsets

The plate size results from the cross-section dimensions of the connected member. By defining the 'Offset' in the four directions, you can respectively define how far the plate protrudes beyond the bounding box of the cross-section. The resulting width and height are indicated in the last rows; these values cannot be modified.

Dimensions and Position

You can specify the plate size directly. The Position is related to the cross-section of the connected member or stub, whereas the vertical offset is measured from the top edge (cross-section side of the negative z-axis) and the horizontal eccentricity is measured from the centroid of the member cross-section.

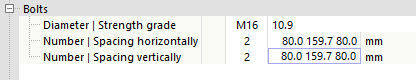

Bolts

If you do not define the bolts separately as Fasteners, you can define the properties in this category.

Select the 'Diameter' and the 'Class' of the bolts from the lists.

Then, enter the 'count' as well as the 'horizontal spacing' and 'vertical spacing' of the bolts. The button here is also disabled

![]() in the graphics area to switch to the symbol display of the parameters.

in the graphics area to switch to the symbol display of the parameters.

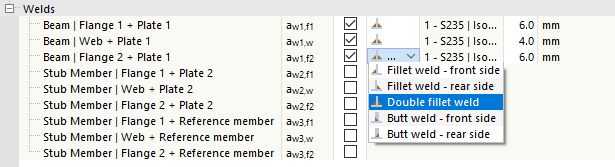

Welds

The last category controls the welds with which the plates are connected to the member or stub end. If you deactivate one of the check boxes, no weld is arranged on the corresponding object.

You can open a list of weld types by clicking in the column to the right of the check box. Various types of fillet and butt welds are available for selection. For fillet welds, you have to specify the thickness of the weld.