The End Plate to Plate component allows you to connect a member to another one using an end plate, a reference plate, a stiffener, a bolt group, and welds.

To Connect

The first category of the component settings manages the definition of a connected member and a reference member.

End Plate

The second category controls the definition of the end plate. Select the plate material from the defined materials or create a new material. Then, enter the thickness of the plate.

You can define the dimensions of the plate either by "'Offsets" or by "Dimensions and position". Select the relevant option from the list.

If you define the end plate by "Offsets", the plate dimensions—using four offsets in the cross-section plane—are derived from the cross-section dimensions of the connected member. That is, how far the end plate overhangs the bounding box of the cross-section. You can check the total plate dimensions in the last rows, but you cannot change them.

If you select the Dimensions and position option, you can directly enter the size of the plate. The position of the end plate is related to the connected member: The vertical position is measured from the upper edge of the section (positive values upwards), while the horizontal eccentricity is measured from the center of gravity of the member section.

Switching between the definition types will not change the position or dimensions of the plate. The values are recalculated to reflect the current definition.

Reference Plate

The next category controls the definition of the reference plate—the plate that is welded to the reference member. Select the plate material from the defined materials or create a new material. Then, enter the thickness of the plate.

Again, you can define the dimensions of the plate either by Offsets or by Dimensions and position.

If you define the plate by Offsets, the width—using the left and the right offset—is derived from the cross-section dimensions of the reference member. That is, how far the end plate overhangs the bounding box of the cross-section. You can check the total plate dimensions in the last rows, but you cannot change them.

If you select the Dimensions and position option, you can directly enter the size of the plate. The eccentricities define the position of the reference plate in the plane of the bounding box. The vertical eccentricity moves the plate along its local y-axis, while the horizontal eccentricity may be used for moving the reference plate along its local x-axis.

Switching between the definition types will not change the position or dimensions of the plate. The values are recalculated to reflect the current definition.

The Stiffened check box specifies whether the reference plate is stiffened or not. If you select this option, the Stiffener category is added where you can define the parameters.

Stiffener

This category is only shown if you have selected the "Stiffened" option for the reference plate. Here, you can define the material and thickness of the stiffening plate(s), as well as their position and shape.

Use the Position options to move the stiffener along the reference member: Upper, Lower, Center, or Both. The Member plate option allows you to align the stiffener with the connected element plates.

The Direction options allow you to select whether the stiffener should be entered as parallel to the connected member or as perpendicular to the reference member. If you want to move the stiffener in the direction parallel to the center line of the reference member, you can specify the corresponding Offset.

Use the Side options to define whether the reference member should be stiffened on both sides or on the side of the reference plate only. The Chamfer options allow you to modify the corners of the stiffener(s).

Bolts

This category manages the properties of the bolts.

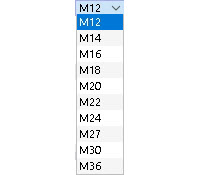

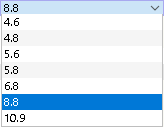

Define the bolt diameter and bolt class in the first row by selecting the respective entries from the lists.

In the next two rows, you can define the spacing of the bolts in the horizontal and vertical directions. The edge and center distances are entered in the line separated by spaces. Missing entries are automatically completed in a way that is consistent with the geometry of the end plate.

Activate the Preloaded bolts function to consider prestress. The preloading force factor and the friction coefficient under the end plate are defined in the Ultimate Configuration.

If you activate the Shear plane in thread option, the lower strength (reduced area) according to the selected design standard is considered for the shear design.

Welds

The last category controls the welds for the individual parts of the end plate. If you clear a check box, this weld will not be applied.

If you select the area to the right of the check box, you will find a list from which you can select the weld type. There are different types of fillet welds and butt welds available.