Modeling Base Plate Connection

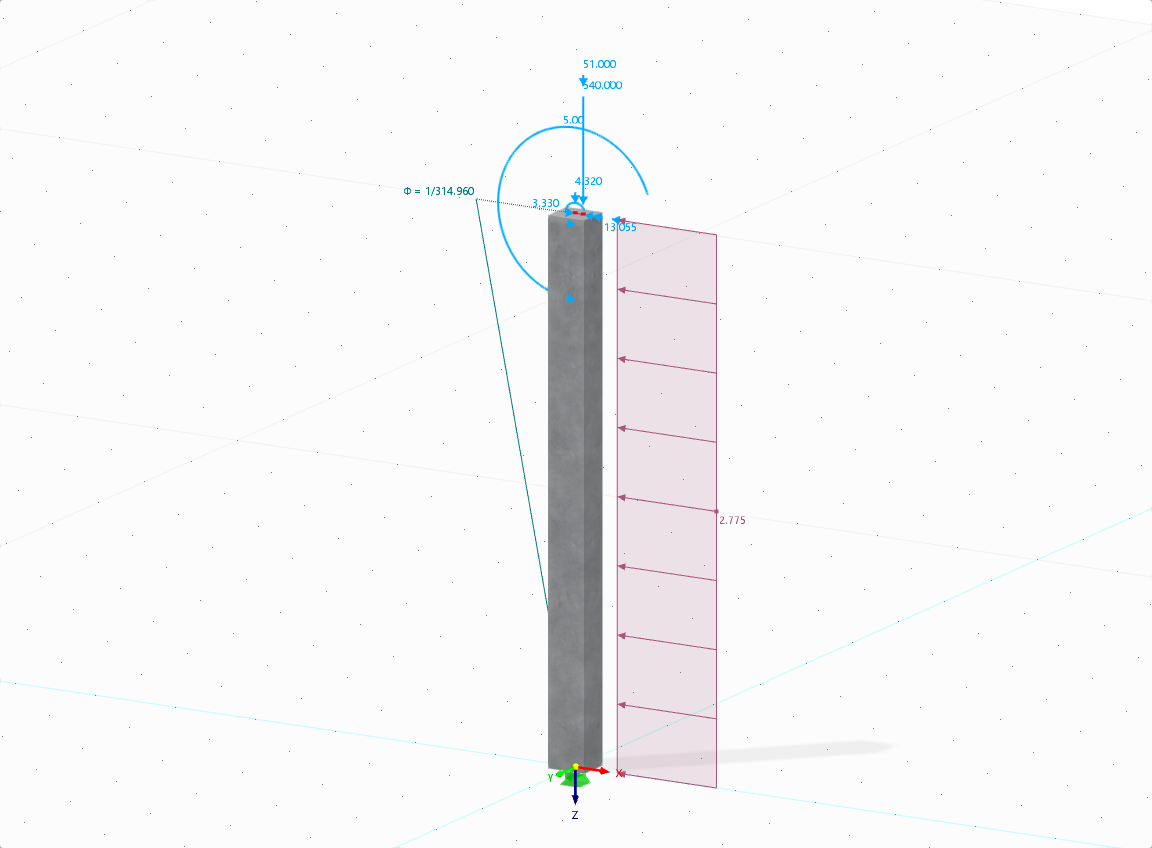

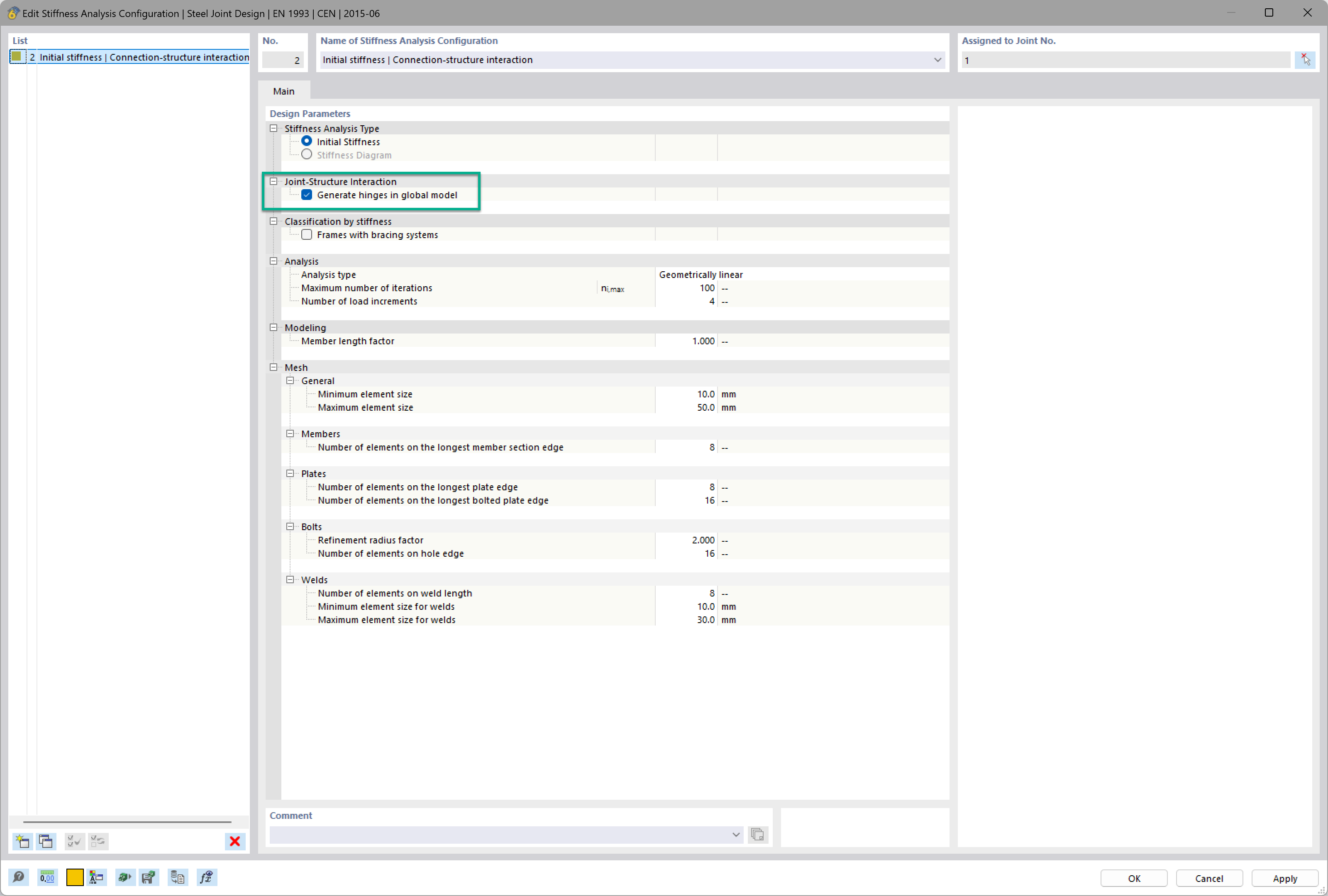

1) In the Main tab, assign the new steel joint to the relevant node. Review the ‘Strength configuration’ to confirm that the default settings are appropriate, making any adjustments as needed (Image 01).

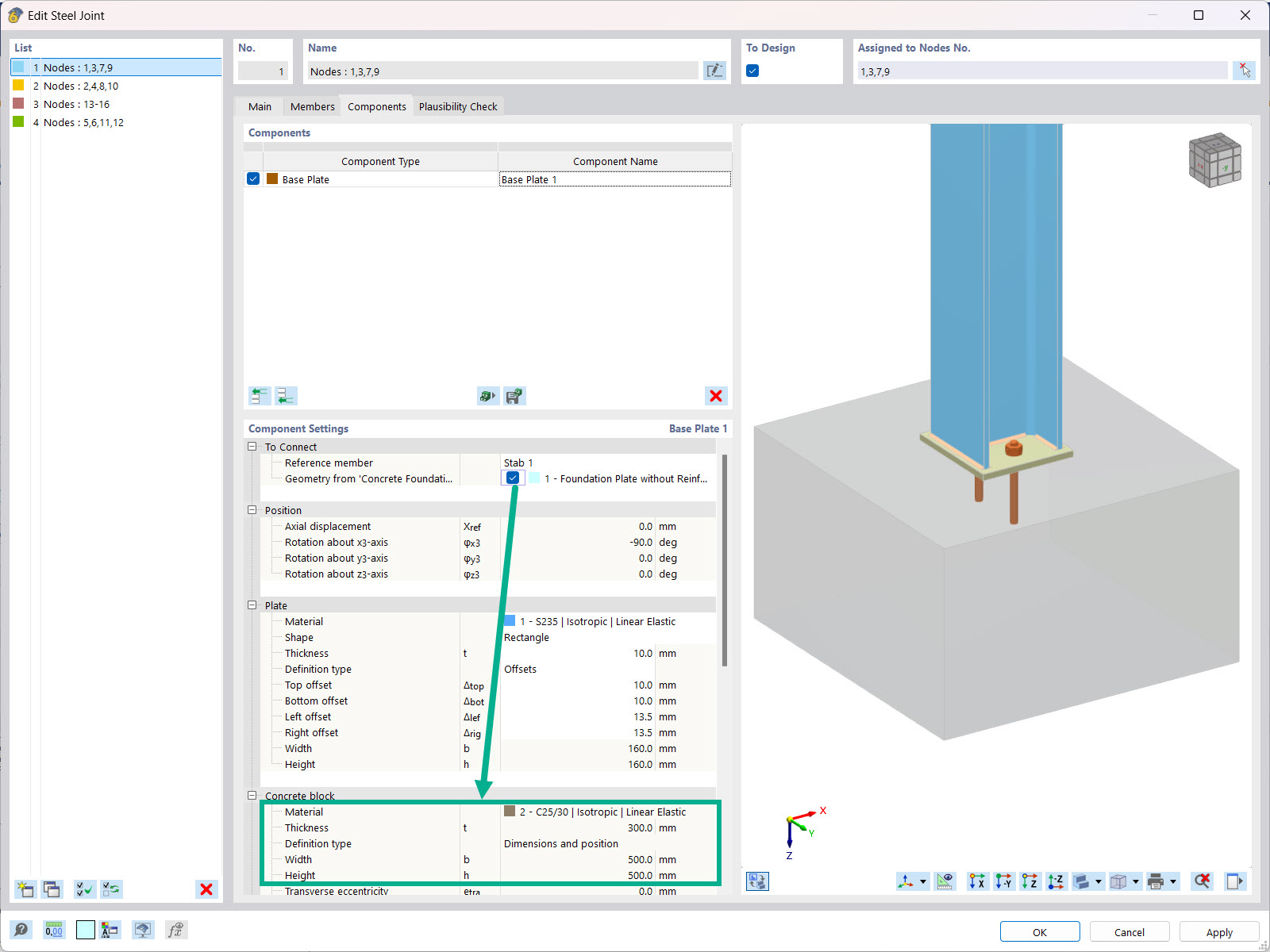

2) In the Components tab, select ‘Insert component at beginning’ and pick ‘Base Plate’ (Image 02).

3) Under ‘Component Settings’, specify the materials, dimensions, and placements for the base plate, concrete block, grout, anchors, and welds. Options to consider cracked concrete and shear transfer through friction are also available (Image 03).

Design Checks According to AISC 360 & ACI 318

The forces in the anchor rods are based on finite element analysis (FEA), which accounts for the stiffnesses of the connecting elements (anchor rods, base plates, concrete block, etc.). Prying action can occur when the flexibility of the base plate causes deformation that increases the tension in the anchor rods. These prying forces are also considered in the FEA calculation.

The following design checks for cast-in anchor rods are provided:

- Bearing resistance of base plate at bolt holes, ϕbRnb

- Steel tension resistance of anchor, ϕatNsa

- Concrete breakout tension resistance, ϕcbtNcbg

- Steel shear resistance of anchor, ϕavVsa

- Concrete breakout shear resistance, ϕcbvVcbg

- Concrete pry-out shear resistance, ϕcpvVcpg

The following design checks will be added in the future:

- Concrete breakout tension resistance for anchors with 11 in ≤ hef ≤ 25 in

- Pullout tension resistance

- Concrete side-face blowout resistance

Other design checks, including concrete bearing compression resistance, weld resistance, and plastic strain of base plates and members are also provided.

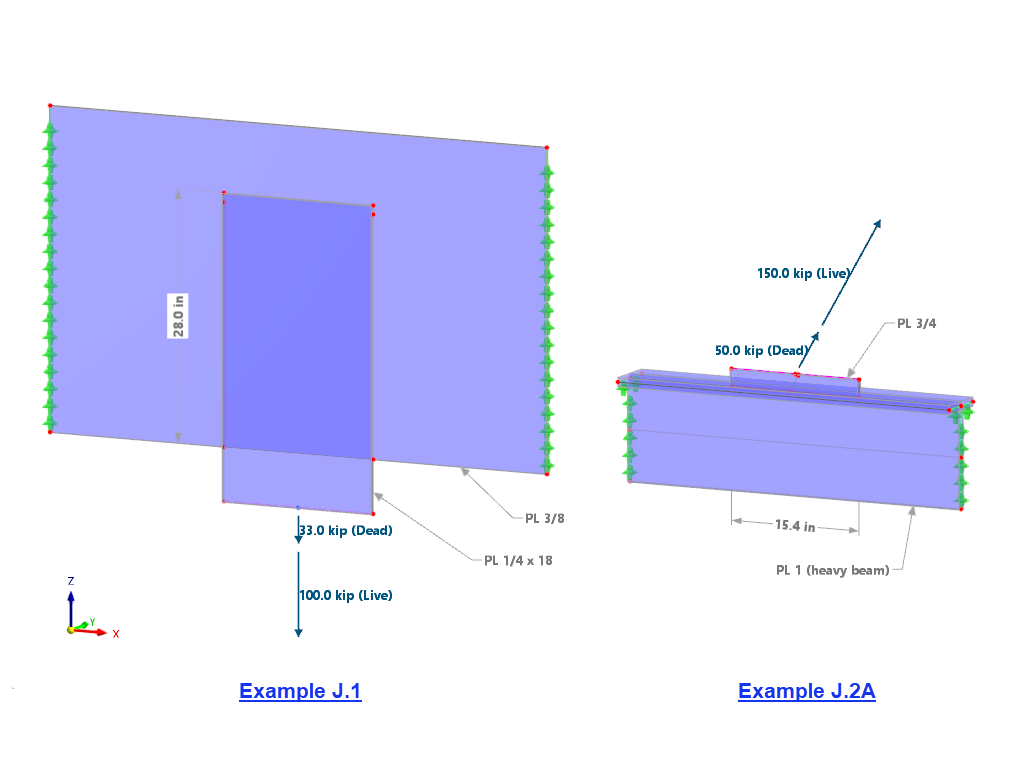

Example

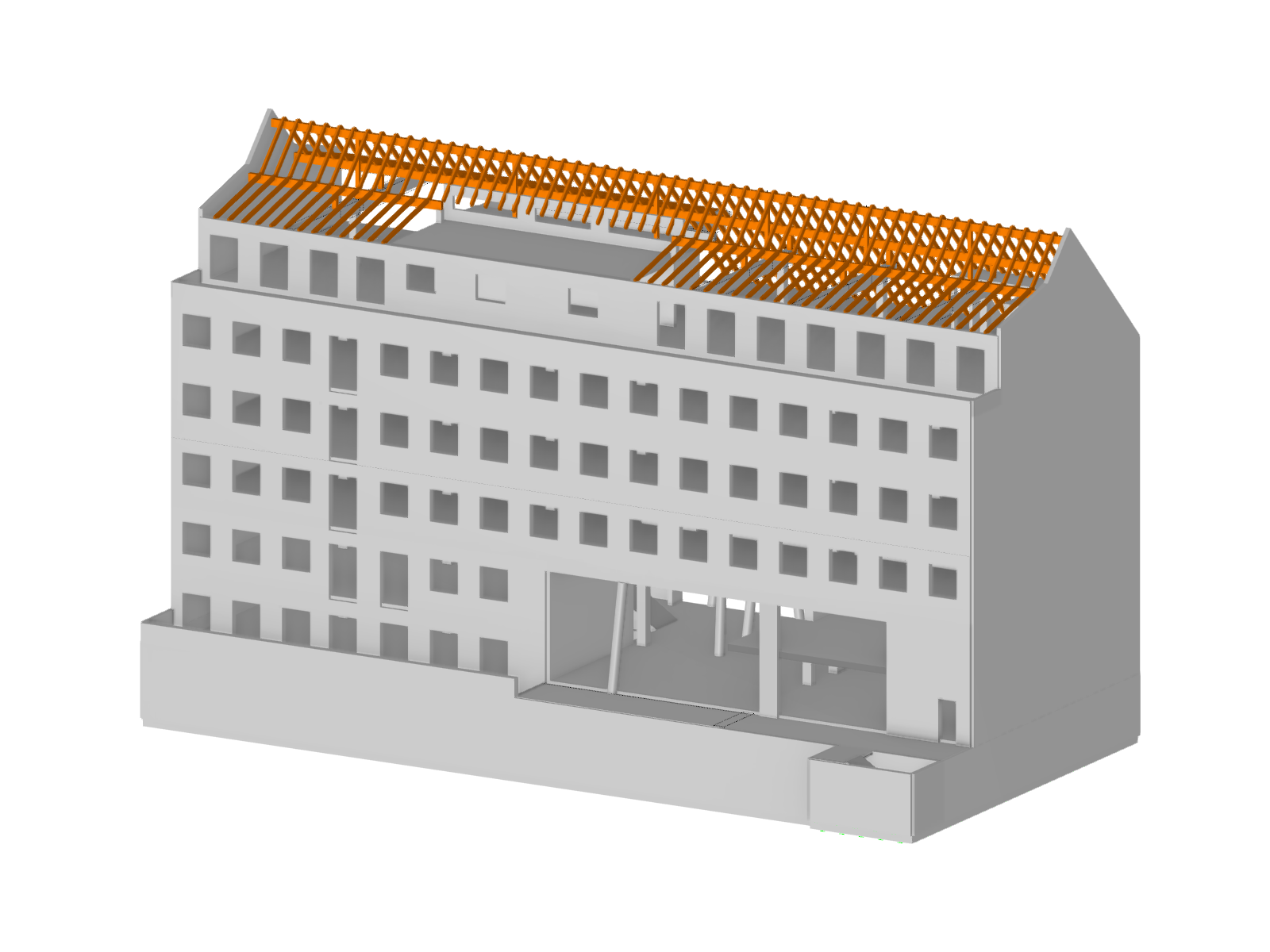

Example 4.7-11 of AISC Design Guide 1 is presented to verify the results from the RFEM model. A base plate connection for a W12x96 column subject to compression and moment is designed in this example. The column is attached to a concrete foundation with a specified compressive strength, ƒ'c = 4,000 psi. The base plate is 2.0 in thick with assumed grout thickness of 1.0 in. The effective embedment length, hef is equal to 18.0 in. The loads and material properties are shown in Image 04.

In the example, the actual extents of the concrete are not given, and it is assumed that there is sufficient area for the anchor rod tension breakout cones to form with respect to the edge distance. To satisfy this assumption, concrete block dimensions equal to 1.5hef + rod spacing +1.5hef are used (66.0 in x 72.5 in).

The complete input for the Steel Joint is shown above in Image 03.

Results

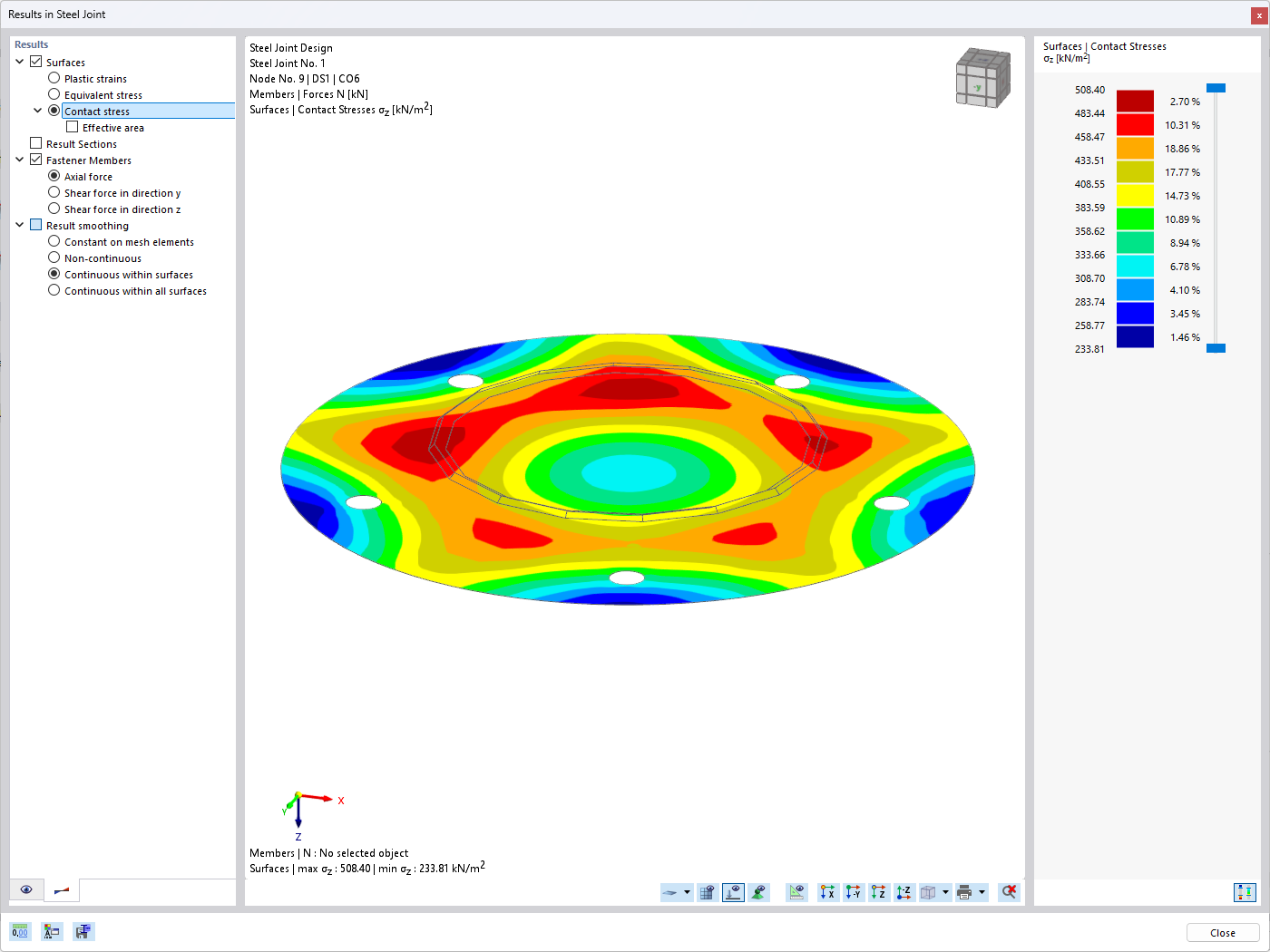

After running the Steel Joint calculation, the result for each component is presented in the Design Ratios by Component tab. Next, select Anchor 1,1 to view the design check details (Image 05).

The design check details provide all of the formulas and references to AISC 360 and ACI 318 standards (Image 06). A note on excluded design checks is also given for clarifications.

Next, select ‘Results in Steel Joint’ to view the internal forces of anchors graphically (Image 07).

The results from AISC and Steel Joints are summarized below, including the reasons for discrepancies.

Anchors

Concrete (Bearing Strength)

The bearing stress of 2.21 ksi is taken from Example 4.7-10 with the assumption A1 = A2, providing the lowest possible strength. The base plate area is calculated as 22 in × 24 in = 528 in2, giving a concrete bearing compressive resistance, ϕPp =2.2 ksi × 528 in2 = 1166.9 kips, assuming the entire base plate area resists compression.

In the Steel Joint add-on, ϕPp is 885.7 kips. Here, it is assumed that A2 >> A1 to satisfy the breakout tension resistance. Additionally, the effective base plate area in compression = 200.438 in2 is based on FEA with a contact stress threshold set to 5% in the Strength Configuration. Lowering this threshold (to as low as 1%) increases the effective area.

Base Plate

The design of the base plate thickness is governed by either the bearing or tension interface. Per the AISC calculations, the required thickness based on bearing is 1.92 in (rounded to 2.0 in), which controls the design, while the thickness from tension is calculated as 0.755 in.

In the Steel Joints, plate design is performed using plastic analysis by comparing the actual plastic strain with the allowable limit of 5% specified in the Strength Configuration. The 2.0-in-thick base plate has a maximum equivalent plastic strain of 0.09%, indicating that a thinner plate may be sufficient. However, reducing the plate thickness may increase tension forces in the anchors.

In most cases, the Steel Joints add-on results in a significantly thinner base plate because it accounts for the base plate's flexibility, unlike the approach in AISC Design Guide 1, Chapter 4.3.1, which assumes a rigid base plate.

AISC Design Guide 1 Appendix B.3 [3] explains how accounting for the flexibility of the base plate can significantly reduce the required thickness. The plate yielding limit state corresponds to upward bending of the base plate at the assumed locations of the yield lines under the upward bearing pressure. This pressure, in turn, is assumed to be constant, which implicitly suggests that the base plate is rigid.

However, for larger base plates with a large footprint, this assumption can lead to excessively large moments at the yield lines, resulting in overly thick base plates.

This is a conservative assumption because a large base plate is also flexible, such that the bearing stresses concentrate under the column flanges and webs. In reality, this type of stress distribution results in significantly lower moments in the base plate, reducing the required thickness.

Conclusion

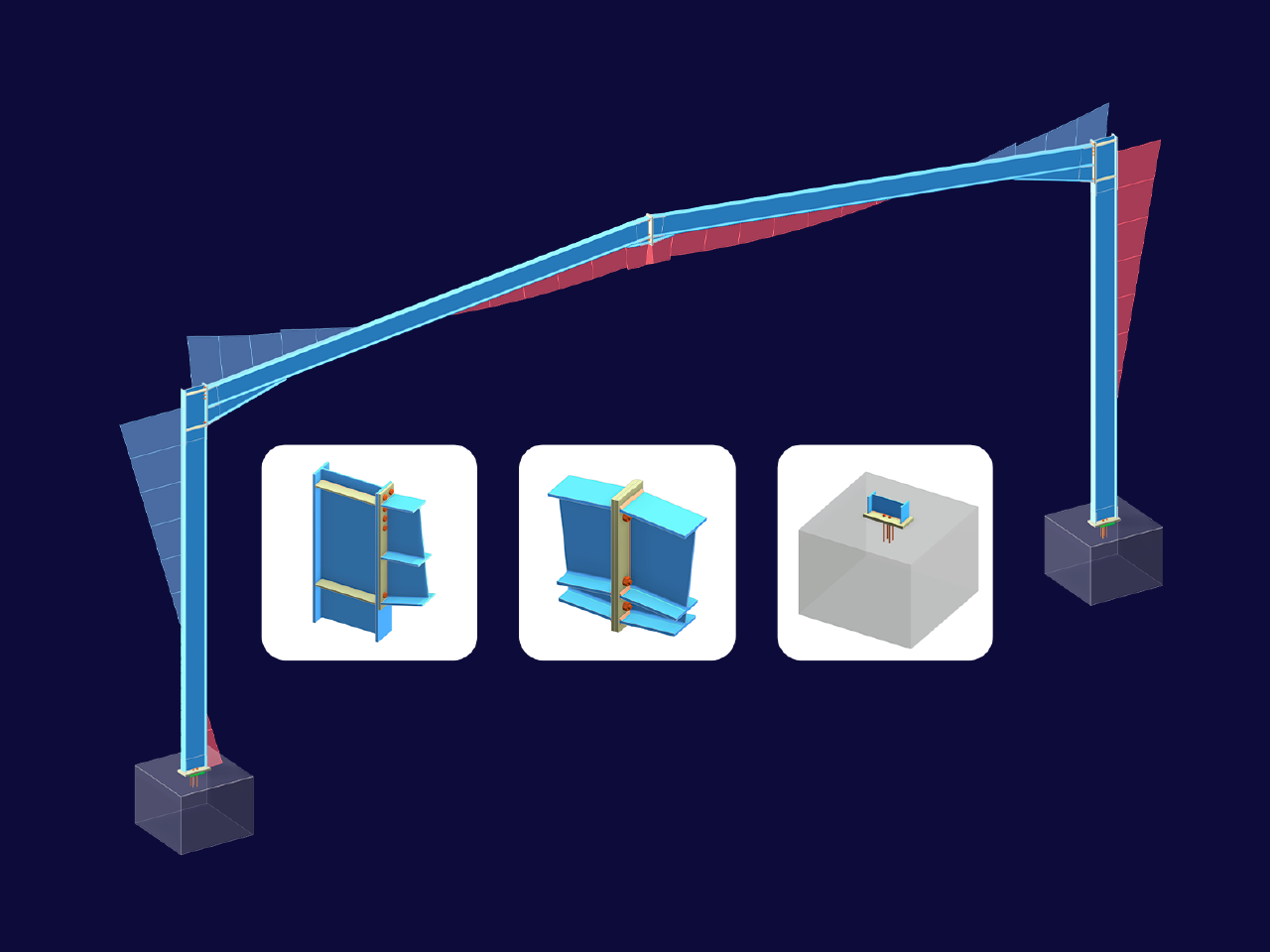

The Steel Joints add-on in RFEM 6 offers an advanced approach to base plate design by considering the flexibility of the base plate and prying actions that may occur. Compared to traditional methods outlined in AISC Design Guide 1, this approach often results in optimized designs with thinner base plates.

By comparing the results with the AISC example, the add-on demonstrates its ability to provide precise and economical solutions for base plate connections.

.png?mw=600&hash=49b6a289915d28aa461360f7308b092631b1446e)