According to EN 1993-1-3 [1], 3.2.2 (1), the average yield strength fya may be used in cases where the yield strength is indicated by the symbol fy if [1], 3.2.2 (4 ) to (8) applies.

The average yield strength fya can be determined by tests on the cold-formed steel cross-section or a simplified calculation method according to [1], Equation (3.1). The increased yield strength fya is calculated according to [1], Equation (3.1) as follows:

|

Ag |

Bruttoquerschnittsfläche |

|

k |

verformungsabhängiger Zahlenwert, k = 7 bei Rollprofilierung, k = 5 bei anderen Profilierverfahren |

|

n |

Anzahl der Umbiegungen um 90° im Querschnitt mit einem Innenradius von r ≤ 5 ⋅ t (Umbiegungen unter 90° sind als Bruchteile von n einzubeziehen) |

|

t |

Bemessungskerndicke des Stahlwerkstoffs vor der Kaltumformung abzüglich aller metallischen Überzüge und organischen Beschichtungen |

Example

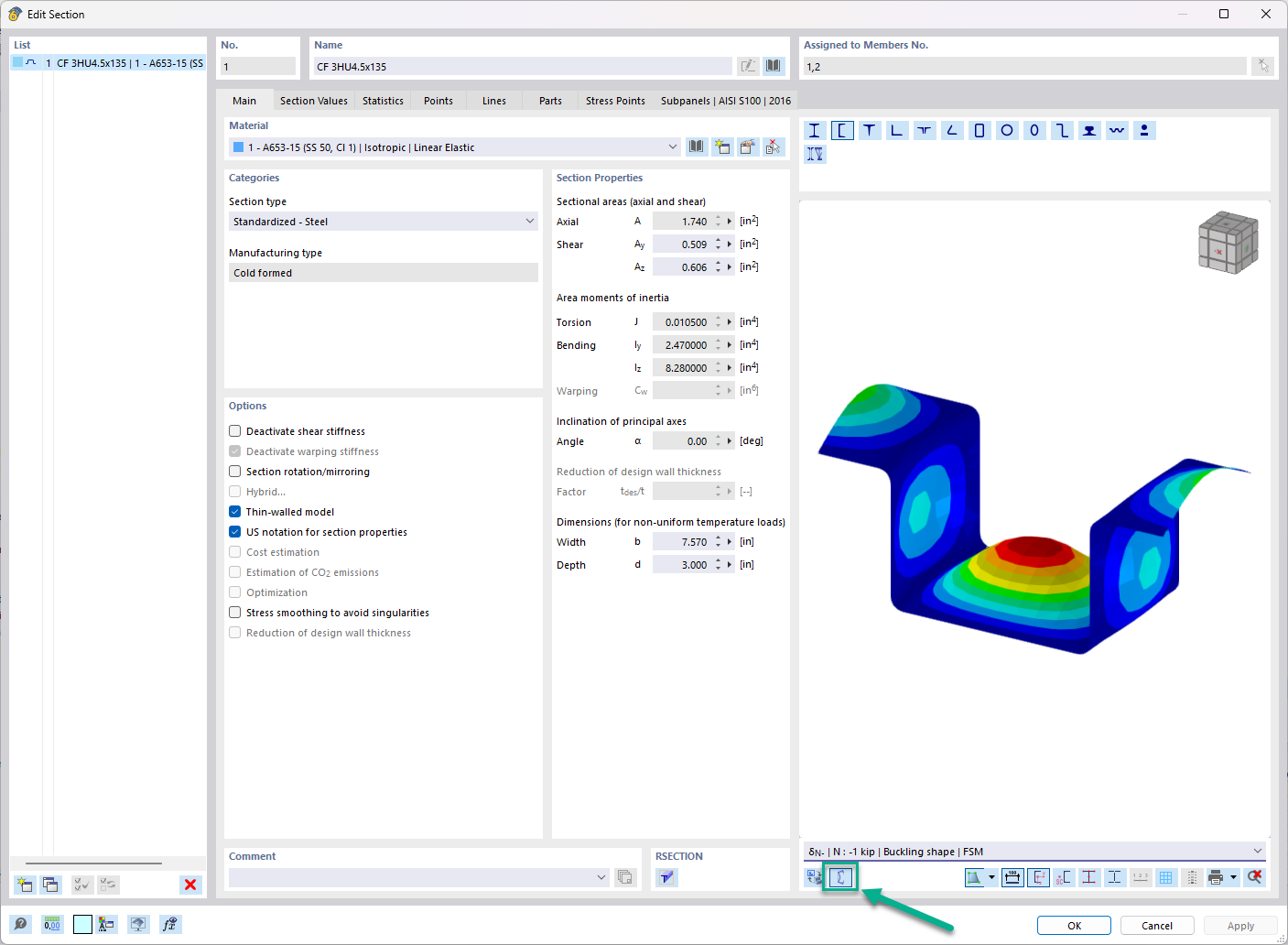

The increased yield strength fya is determined for the sigma section shown in Figure 01 from S 355 EN 10025-2.

fyb = 35.5 kN/cm²

fu = 51.0 kN/cm²

Ag = 7.06 cm²

k = 7 for roll profiling

r = 2 mm ≤ 5 ⋅ 2.5 = 12.5 mm → all deflections may be applied

RF-STEEL Cold-Formed Sections

Cold-formed sections can be designed according to [1] and EN 1993-1-5 [2] with the RF-/STEEL Cold-Formed Sections module extension. The increased yield strength fya is considered in RF-/STEEL Cold-Formed Sections according to [1], Equation (3.1). It is assumed that the cross-section was created by roll profiling (for example, the deformation-dependent numerical value is applied with k = 7).

The increased yield strength fya is displayed in the result tables of RF-/STEEL Cold-Formed Sections. Image 02 shows the increased yield strength fya for the sigma section of this example.

.png?mw=350&hash=c6c25b135ffd26af9cd48d77813d2ba5853f936c)

.png?mw=512&hash=4a84cbc5b1eacf1afb4217e8e43c5cb50ed8d827)

_1.jpg?mw=350&hash=ab2086621f4e50c8c8fb8f3c211a22bc246e0552)

-querkraft-hertha-hurnaus.jpg?mw=350&hash=3306957537863c7a7dc17160e2ced5806b35a7fb)

.png?mw=600&hash=49b6a289915d28aa461360f7308b092631b1446e)