Two methods are available for the design of a weld according to EN 1993-1-8 [1]. The engineer can use the direction-related or the simplified method for the design.

Basically, the direction-related method is more cost effective, whereas the simplified method has identical results parallel to the axis of the weld in case of only shear stresses in the fillet weld area.

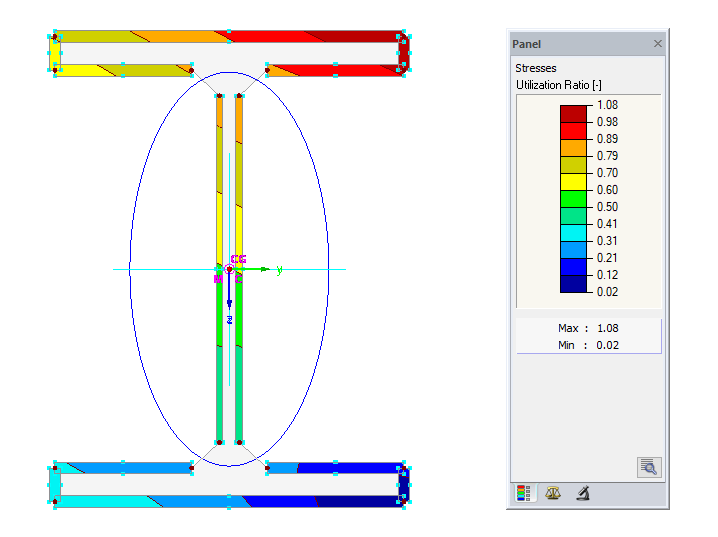

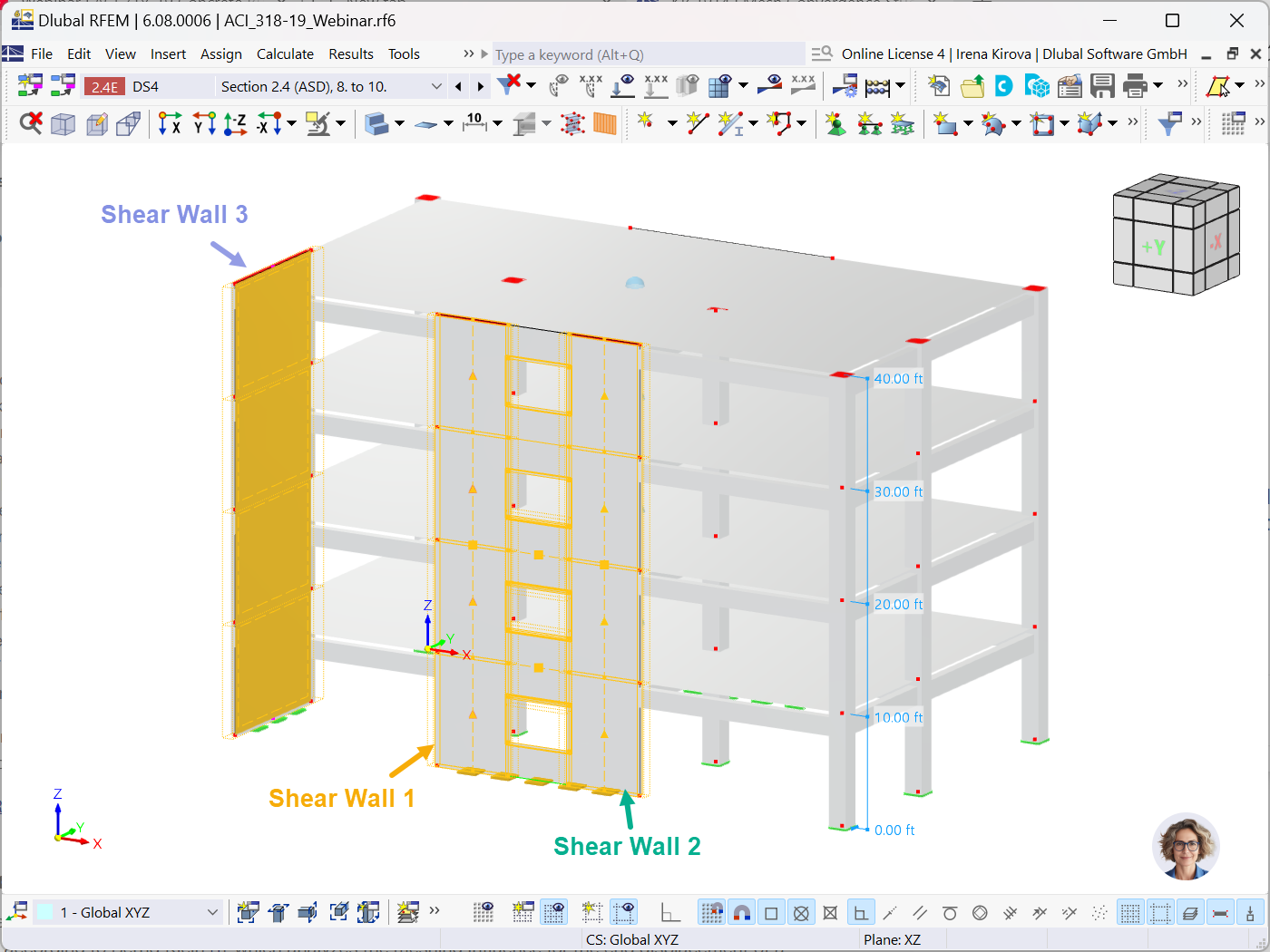

In the present example of an HEA cross-section, the design with the simplified method according to EN 1993-1-8, Section 4.5.3.3 will be carried out quickly and easily with the SHAPE-THIN stand-alone program.

The acting internal forces can be entered in Table 3.1:

N = -1,190 kN

- Vy = 180 kN

- Vz = 370 kN

- My = 225 kNm

- Mz = 26 kNm

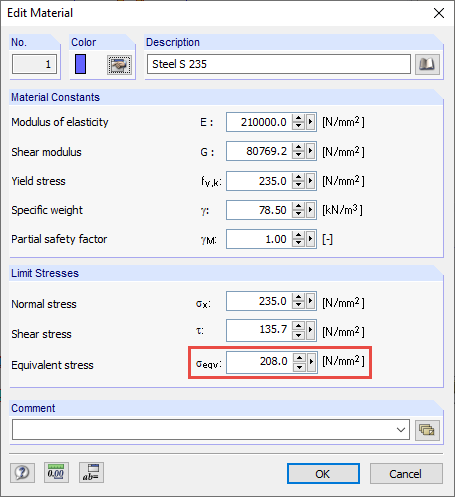

The design value of the shear strength for the weld is calculated with the formula

as

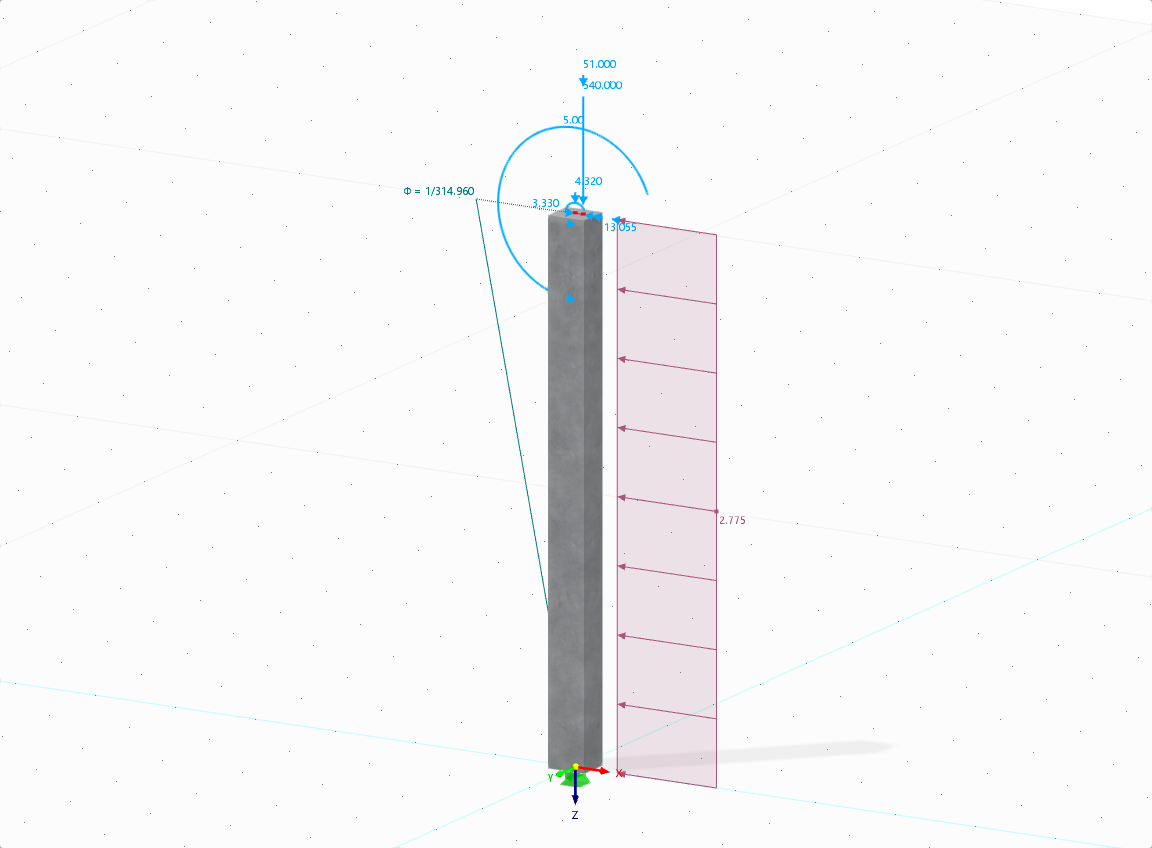

The value in SHAPE-THIN must be adjusted in the material properties, because it is different from the design yield strength for the cross-section design (see Image 02).

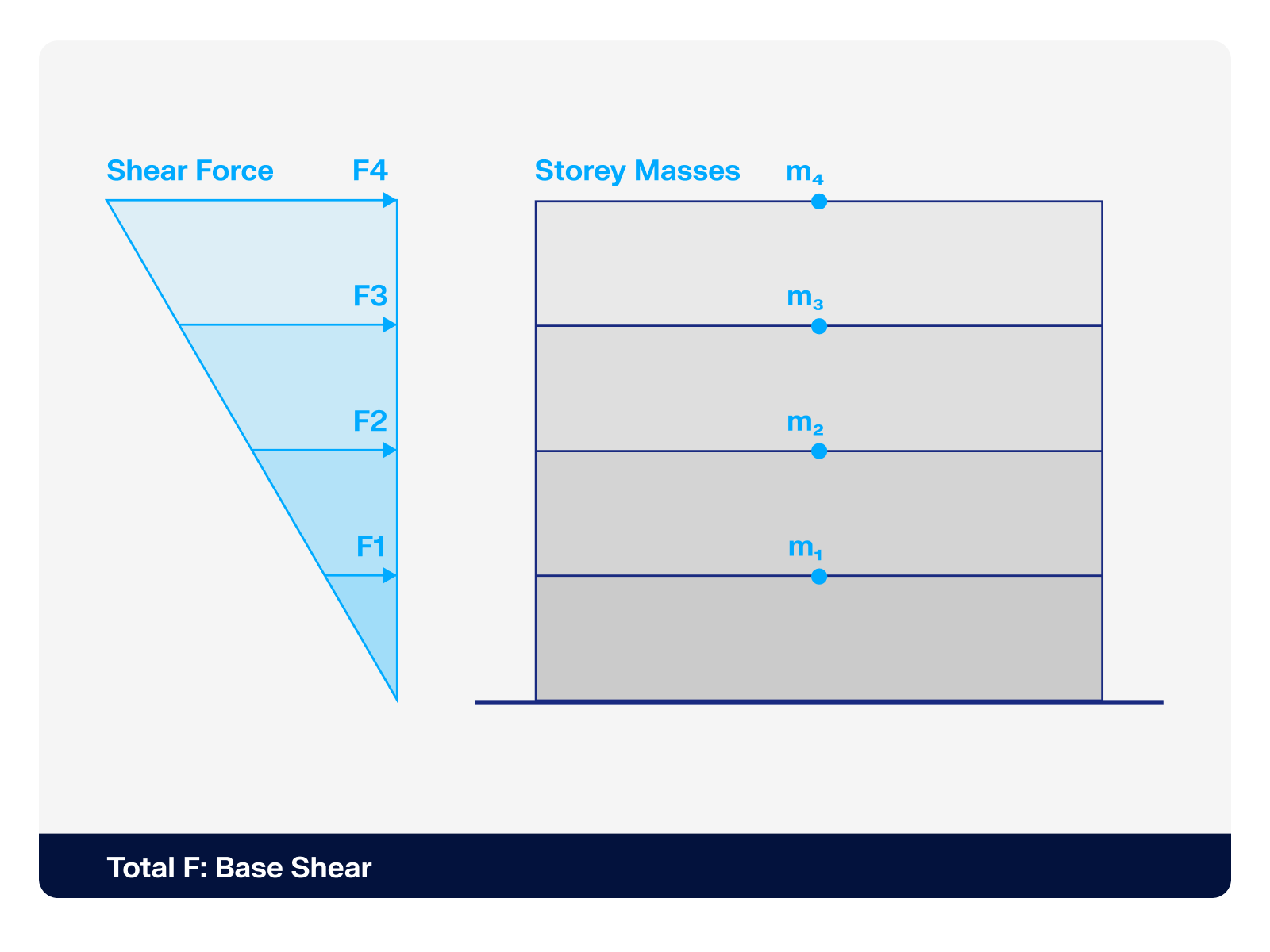

On the side of the loading, the equivalent stress is calculated as a resultant force:

This must be set in the calculation parameters in SHAPE-THIN, because the default setting corresponds to the equivalent stress according to Mises (see Image 03).

The design result in SHAPE-THIN is directly shown graphically. The ratio of the welds on the flange and web can be determined quickly using the color gradient.

.png?mw=512&hash=4a84cbc5b1eacf1afb4217e8e43c5cb50ed8d827)

_1.jpg?mw=350&hash=ab2086621f4e50c8c8fb8f3c211a22bc246e0552)

-querkraft-hertha-hurnaus.jpg?mw=350&hash=3306957537863c7a7dc17160e2ced5806b35a7fb)