The rotational stiffness of many connections previously considered as "pinned" is so great, according to EC 3, that they fall under the "ductile" category. This means that in theory, they can transfer smaller bending moments and should be considered as a spring in the static system.

In fact, there are no pinned‑like situations in the ultimate limit state because (for example) end plates deform plastically. In order to allow this, the following checks have to be done, among other things:

a) Ensure sufficient rotation capacity. For example, it is necessary to ensure that the girder flange does not join the column, thus forming a larger lever arm and therefore greater stiffness.

b) Ensure sufficient ductility. This is necessary to prevent the connection from failing abruptly. Bolts and welds are "brittle" components. By contrast, end plates, for example, deform plastically, as already described. Thus, there must be a certain relation between bolt and end plate stiffness. In the final analysis, you often have to select a higher bolt stiffness class than usual.

These checks are described in the Directive "ECCS TC10: European Recommendations for the Design of Simple Joints in Steel Structures, First Edition 2009", though not yet in EN 1993‑1‑8.

Since standardization is not yet fully regulated and in order to facilitate the transition, you can also deactivate the "ductility check" option.

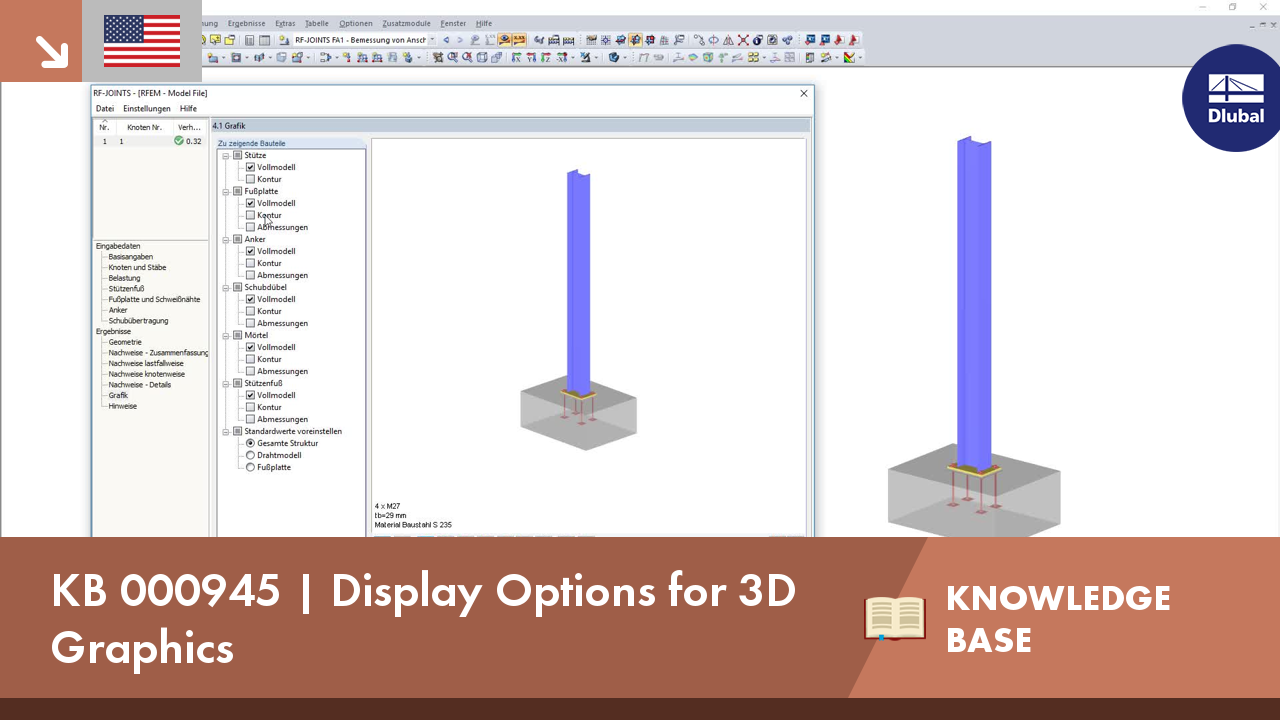

.png?mw=350&hash=c6c25b135ffd26af9cd48d77813d2ba5853f936c)

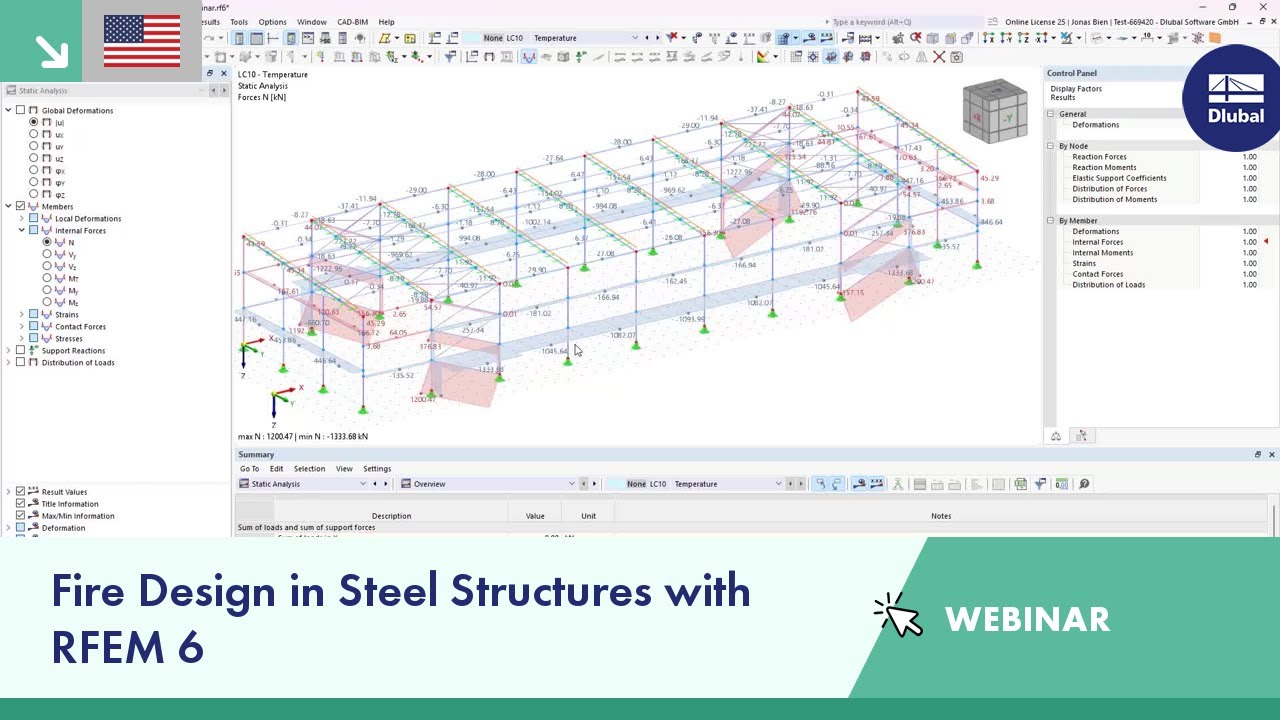

.png?mw=512&hash=831a9308cb08f34e4734dfdce7c09ccf15f76cb6)

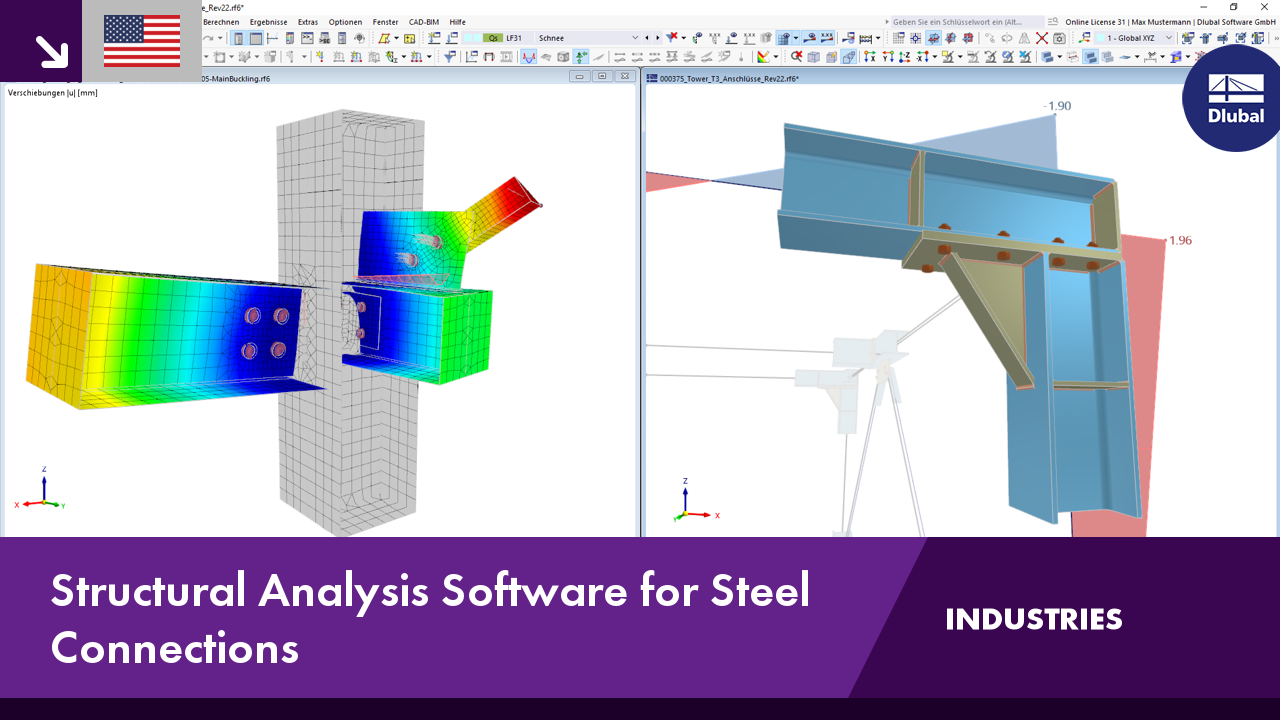

_1.jpg?mw=350&hash=ab2086621f4e50c8c8fb8f3c211a22bc246e0552)

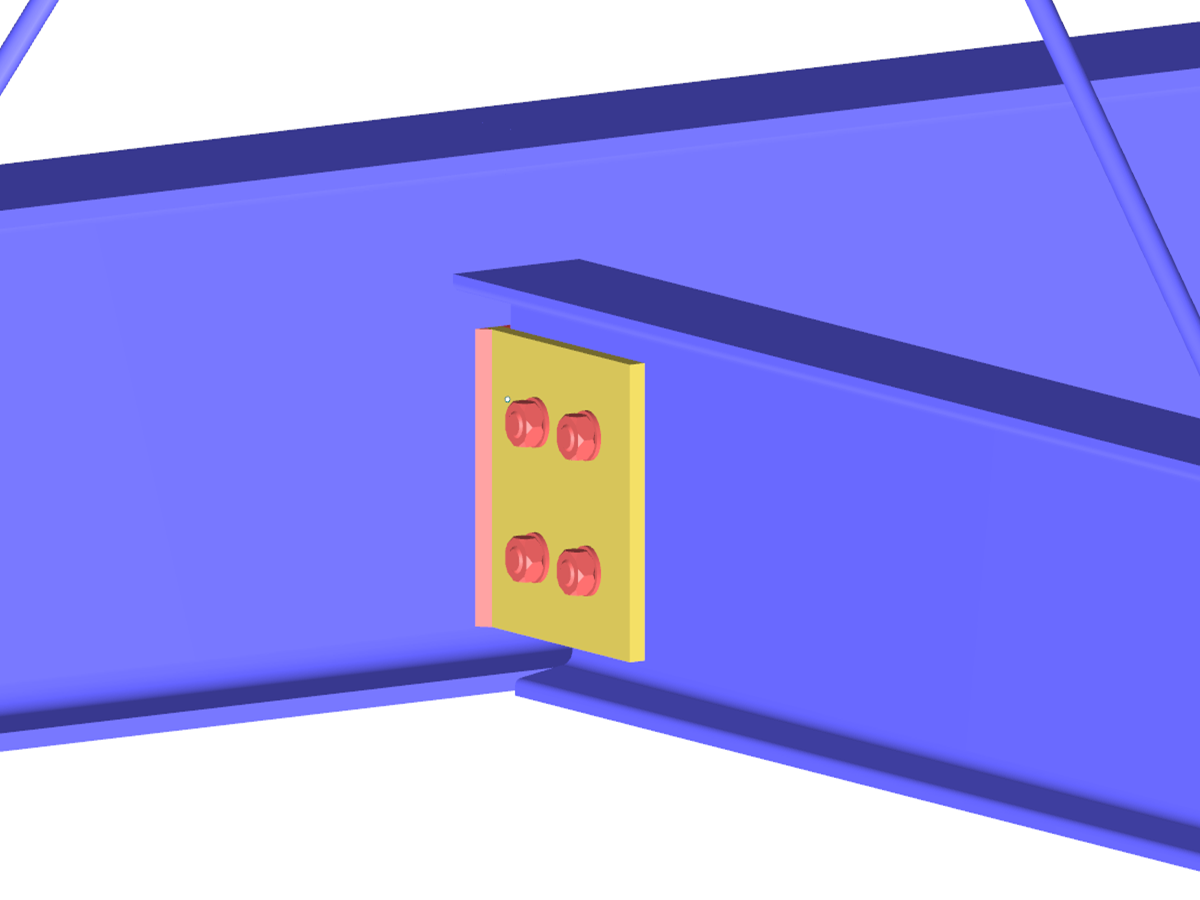

.png?mw=600&hash=49b6a289915d28aa461360f7308b092631b1446e)