Dowel-Laminated Timber (DLT) or Nail-Laminated Timber (NLT) in RFEM 6

How can I design dowel-laminated timber (DLT) or nail-laminated timber (NLT) in RFEM 6?

Amy Heilig serves as the CEO of our USA office based in Philadelphia, PA. She also offers sales and technical support while actively contributing to the development of Dlubal Software programs tailored for the North American market.

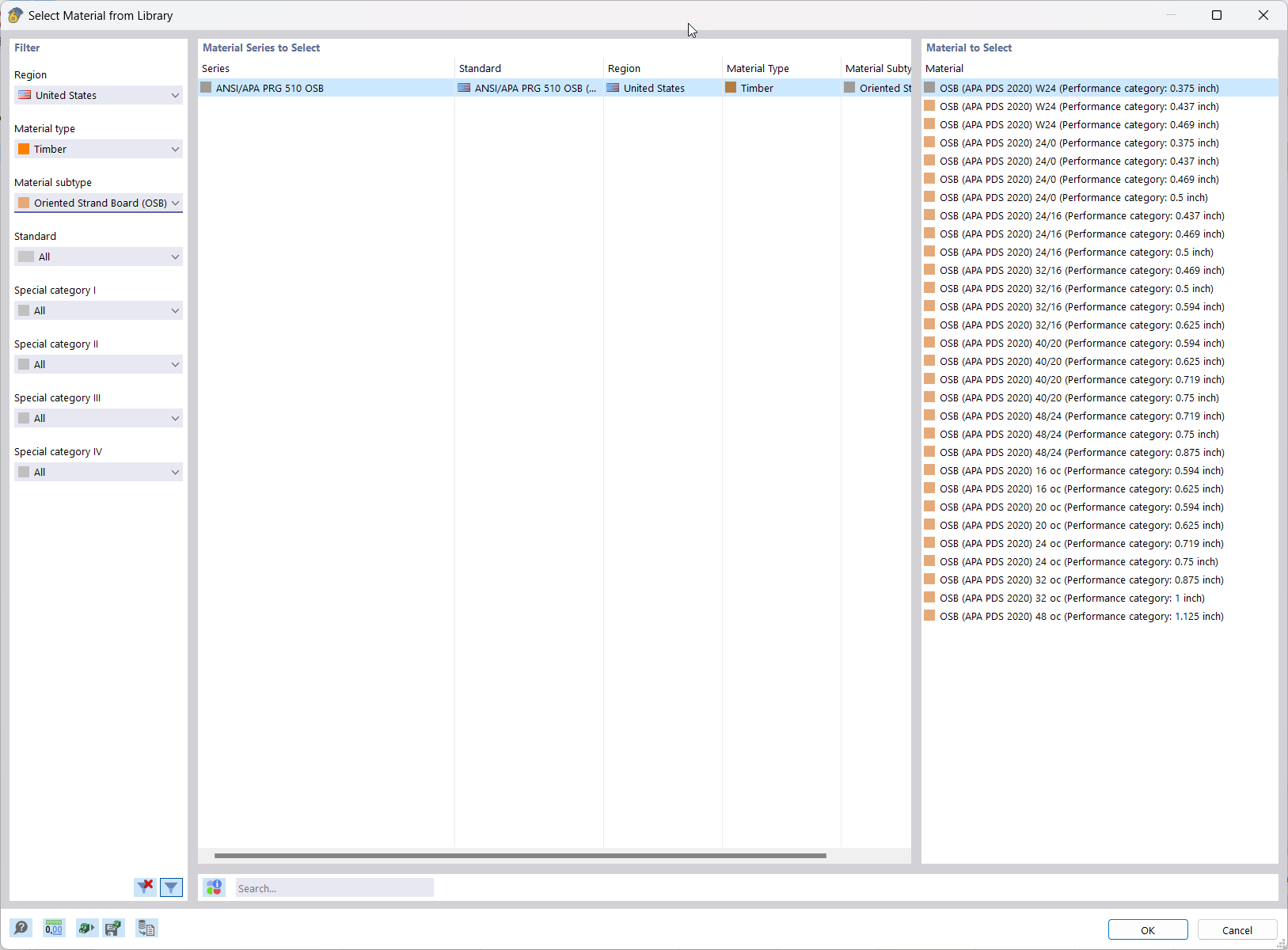

In RFEM, the oriented strand board (OSB) material is available for the USA and Canada. The material parameters are taken from the "Panel Design Specification manual".

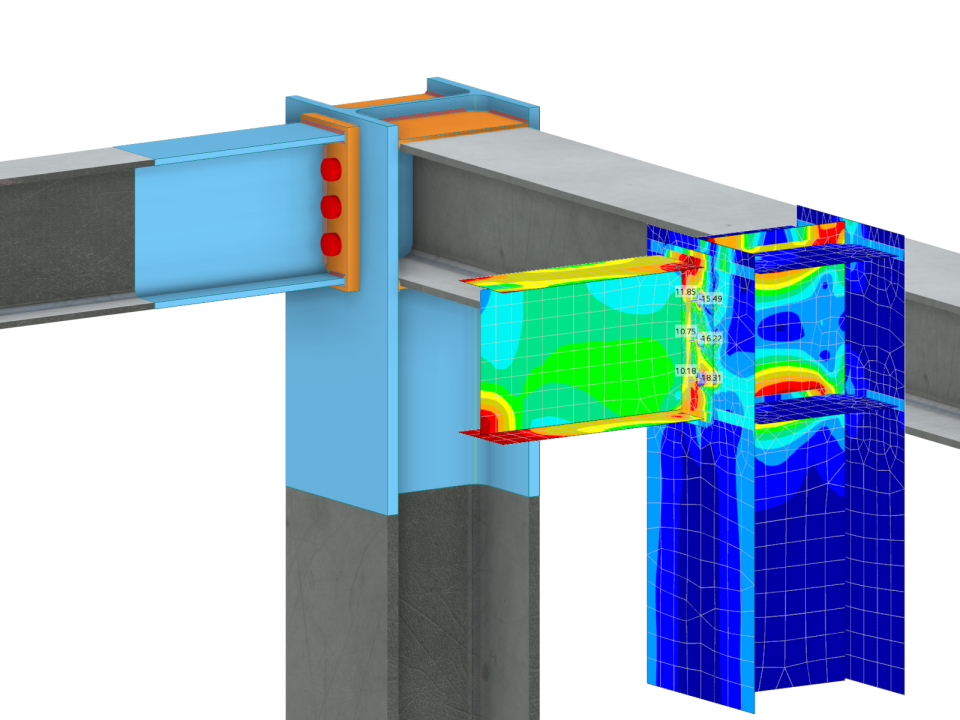

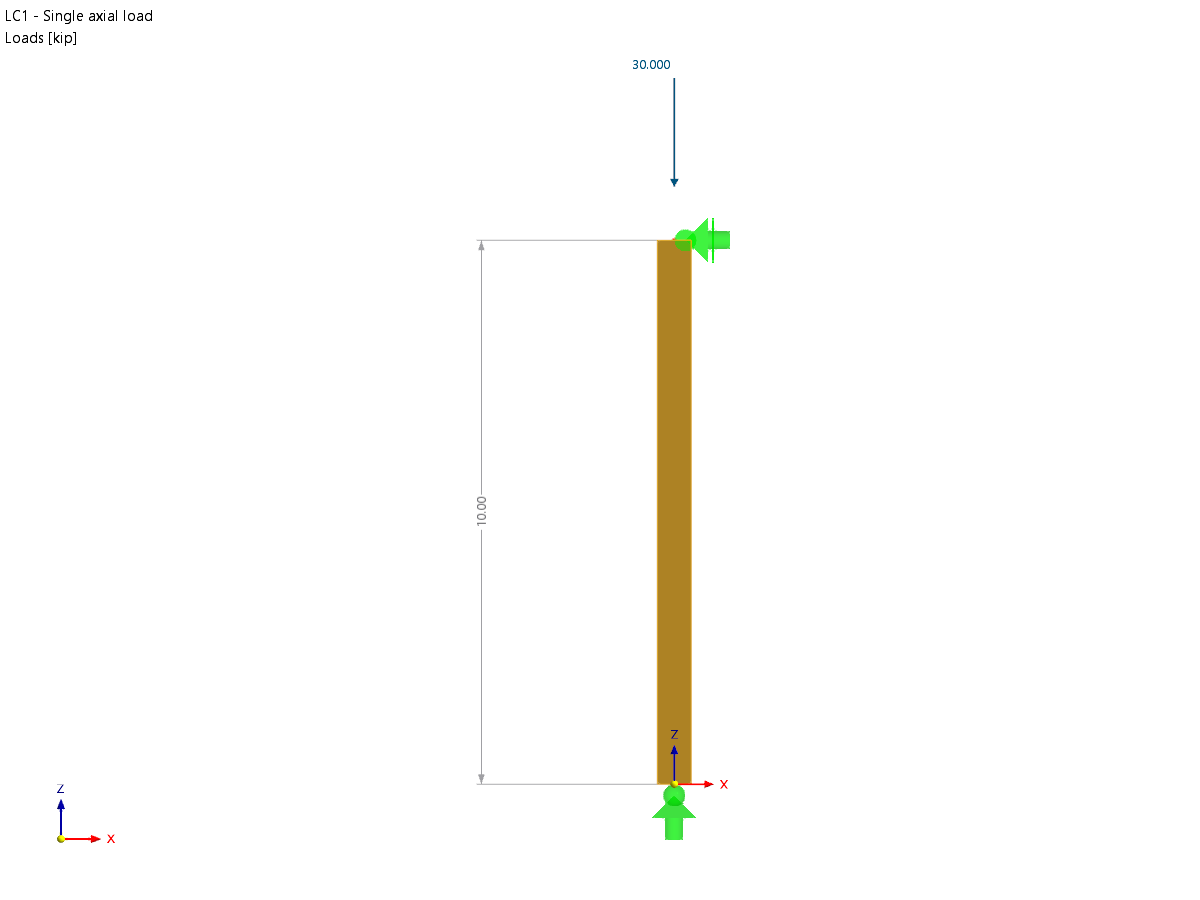

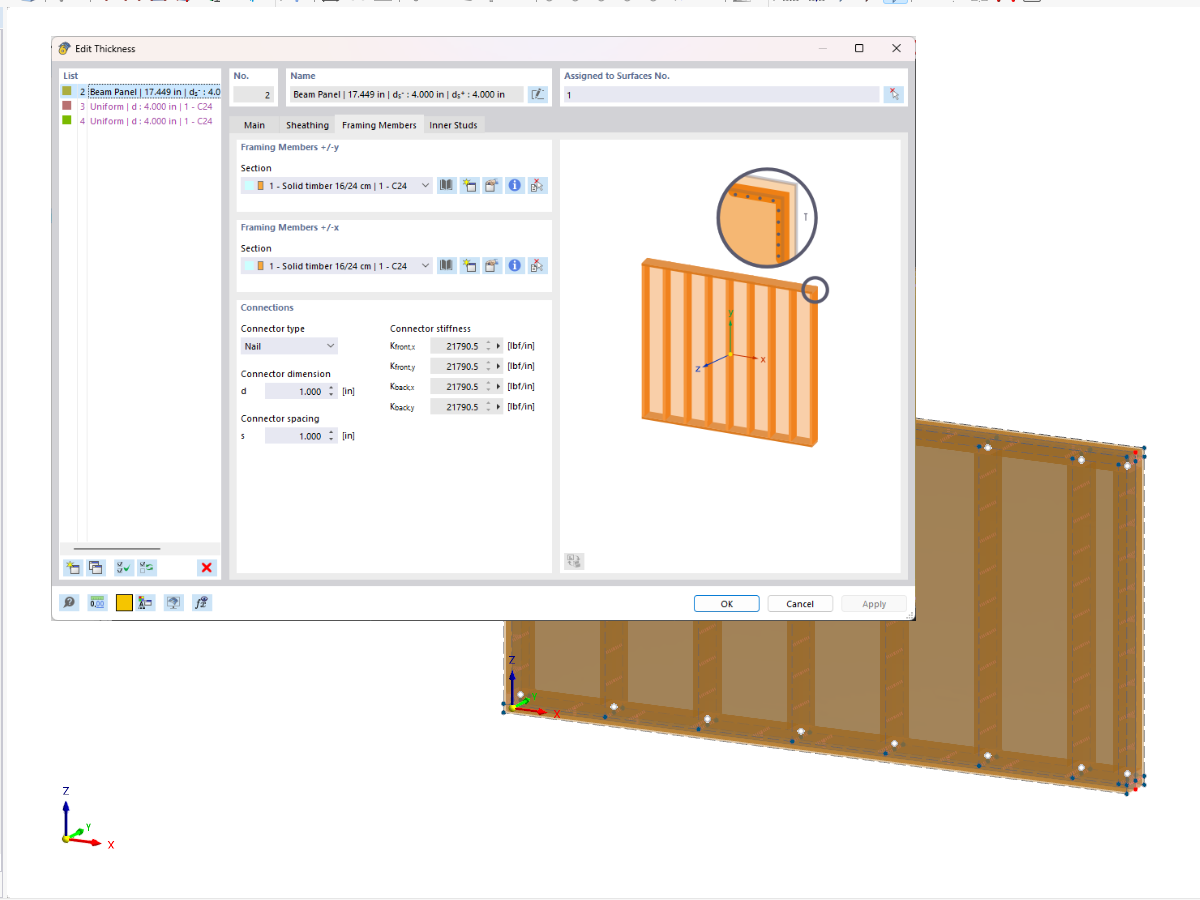

Using the "Beam Panel" thickness type, you can model timber panel elements in 3D space. Simply specify the surface geometry and the timber panel elements are automatically generated using an internal member-surface construct, including the element connection stiffness. The Beam Panel thickness type is defined using the Multilayer Surfaces add-on.

A "beam panel" provides you with the following advantages:

- Single-sided or double-sided sheathing

- Automatic calculation of a semi-rigid coupling between studs and sheathing

- Nailed sheathing connection

- Stapled sheathing connection

- User-defined sheathing connection

- Representation as a complete geometric 3D object (frame, studs, surface, etc.), including eccentricity and automatically calculated stiffness between elements

- Consider openings via surface cells

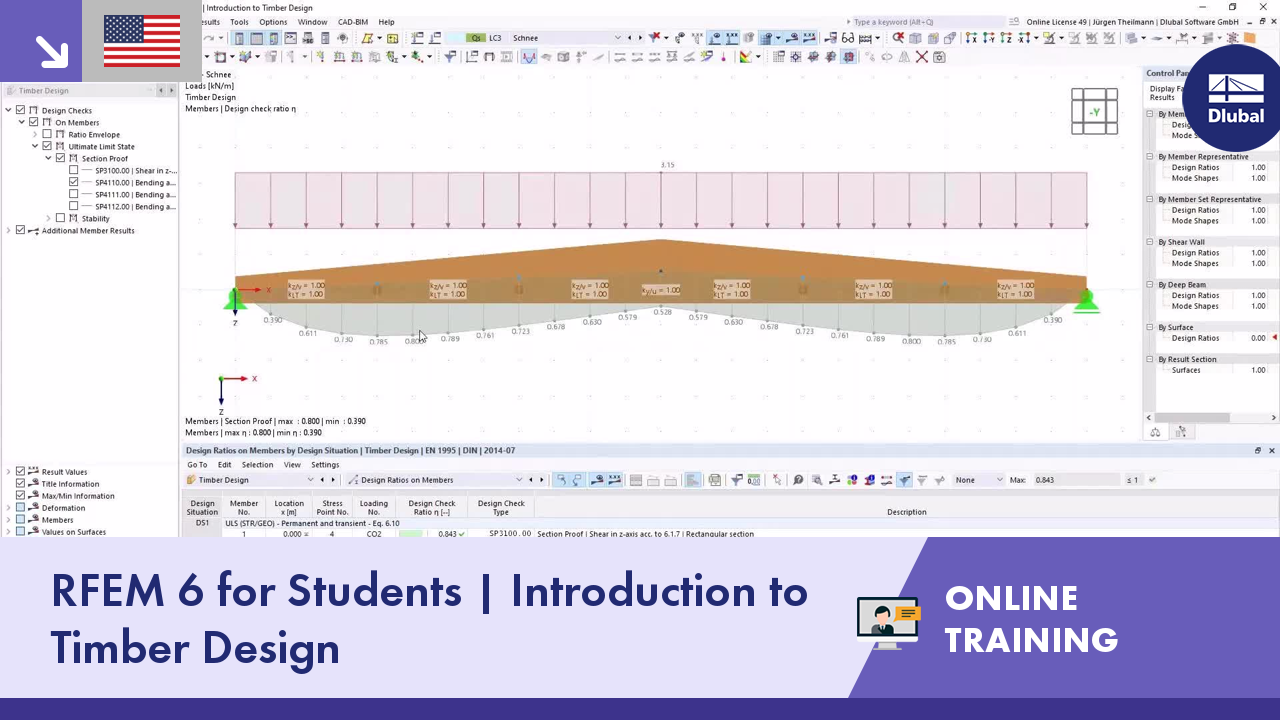

- Design of the individual structural elements utilizing the Timber Design add-on (full shear wall design planned for a future release)

- Other material options available (e.g., particle board, gypsum, or fiberboard sheathing with cold-formed steel sections)

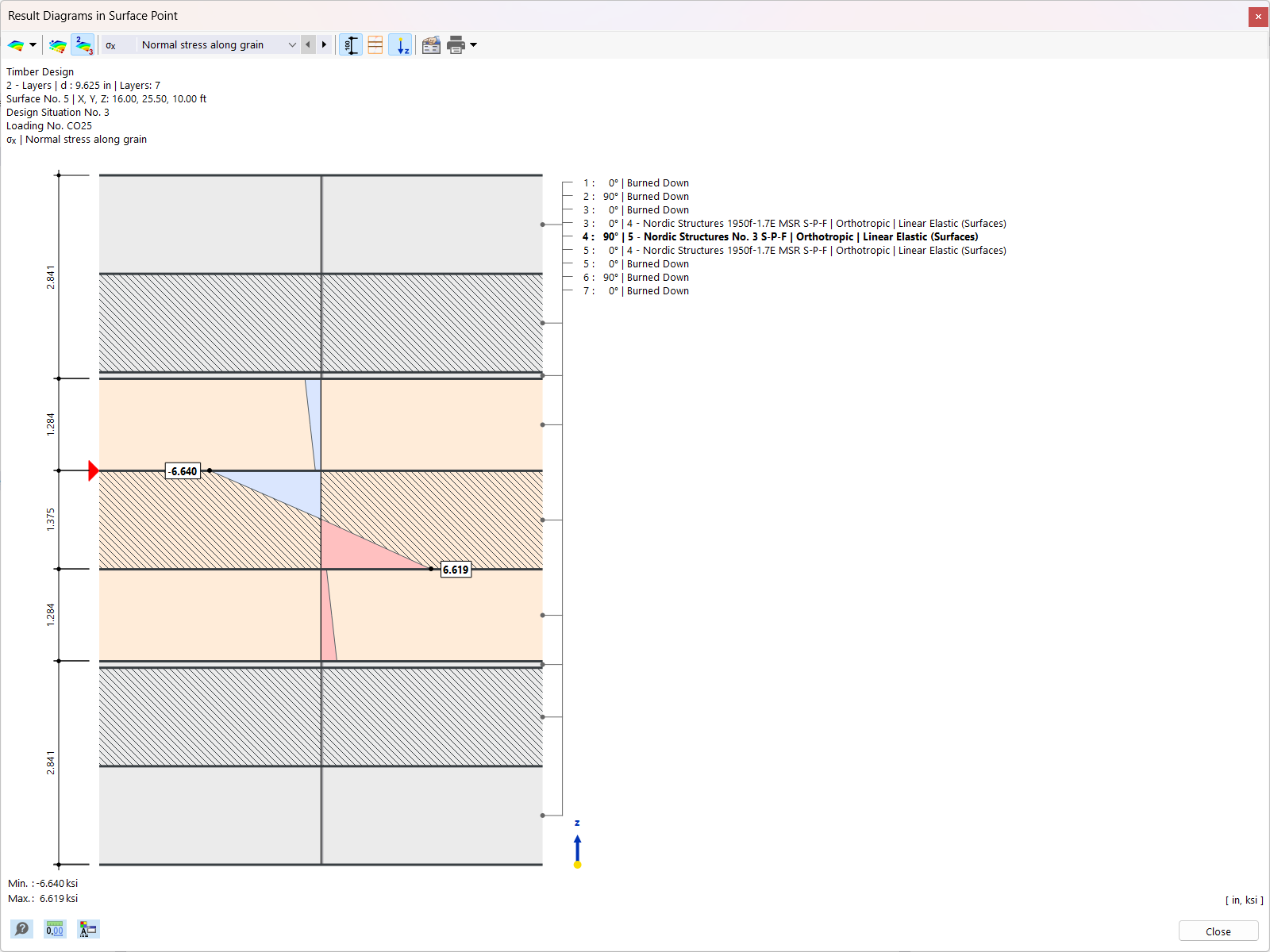

You have the option to perform the fire resistance design of surfaces using the reduced cross-section method. The reduction is applied over the surface thickness. It is possible to perform the design checks for all timber materials allowed for the design.

For cross-laminated timber, depending on the type of adhesive, you can select whether it is possible for individual carbonized layer parts to fall off, and whether you can expect increased charring in certain layer areas.

.png?mw=512&hash=4e74affa9ad0c7b703151c5085ac9b8e59171c23)

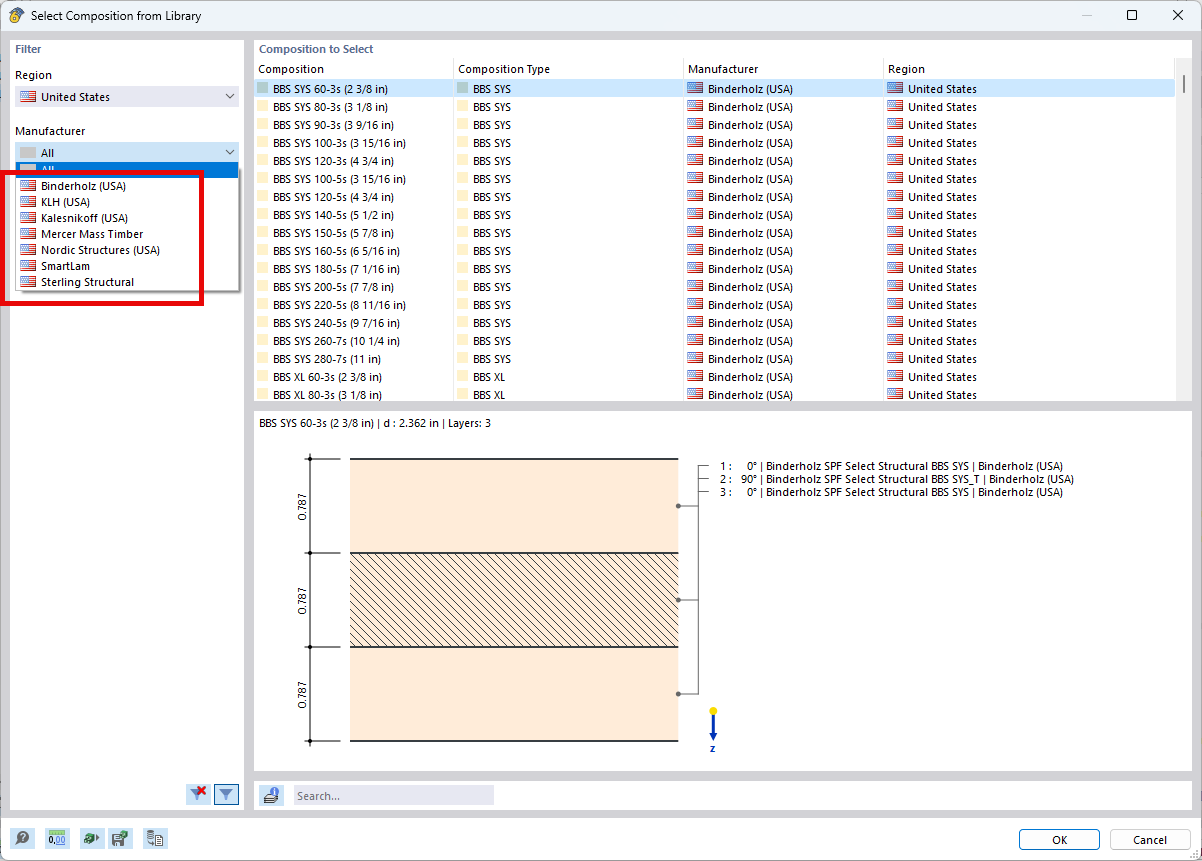

Among others, the following cross-laminated timber manufacturers are available in the layer structure library:

- Binderholz (USA)

- KLH (USA, CAN)

- Kalesnikoff (USA, CAN)

- Nordic Structures (USA, CAN)

- Mercer Mass Timber

- SmartLam

- Sterling Structural

- Superstructures listed in Lignatec Edition 32 "Cross-Laminated Timber of Swiss Production"

By importing a structure from the layer structure library, all relevant parameters are adopted automatically. The library is continually updated.

.png?mw=350&hash=87067b88e84e78e23f7a538dec586f8442297bd4)