The Thicknesses table as well as the 'Stress-Strain Analysis' navigator category lists all thicknesses in the model with the corresponding materials. The specifications of the thickness types are only informative.

The font color allows you to see how the thicknesses are considered in the analysis.

| black | The Thickness is used both in the model and in the Objects to Analyze. |

| Blue | The thickness is not used in the model. |

| gray | Thickness is not assigned to any of the Objects to Analyze. |

Remove thicknesses from analysis

For all valid thicknesses, you can exclude all surfaces from the stress-strain analysis by clearing the 'To Analyze' check box, to which the thickness is assigned. The surfaces are thus sorted in the tables Objects to be Analyzed - Stresses and Objects to be Analyzed - Stress Ranges in the column 'Not Valid/Deactivated' and removed from the analysis.

Use other thickness for analysis

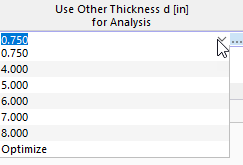

If you want to use a different thickness for the stress analysis than for the RFEM calculation, you can select an alternative in the 'Use Other Thickness d [mm] for Analysis' column. This action has no influence on the internal forces: They are also used for the modified thickness in the stress analysis.

When a different thickness is selected, further options are available in the cell shortcut menu (opens by right-clicking it):

- Export Thickness to RFEM

- Export all thicknesses to RFEM

- Import Thickness from RFEM

- Import All Thicknesses from RFEM

Optimize thickness

As an alternative to adjusting the thickness manually, the program can determine the optimal thickness. You can access the optimization by using the list in the 'Use Other Thickness d [mm] column' for the analysis (see imageSelect Other Thickness for Analysis). You can also link the optimization dialog box by double-clicking the table row or by clicking the #button.image@024184#in the table toolbar.

In the editing dialog box for the thickness, select the Stress analysis optimization check box in the 'Main' tab. Then, you can define the boundary conditions in the 'Stress Analysis Optimization' tab: the 'Minimum thickness', the 'Maximum thickness', and the 'Thickness optimization step' (the increment between the analyzed thicknesses).

During the optimization, the program determines the smallest possible thickness with a utilization that is lower than in the Global Settings dialog box.

For this "simplified thickness optimization", the same conditions apply as for the use of an alternative cross-section described above: During optimization, the design checks are carried out with the internal forces of the model. The optimal variant is then entered into the table.

For a comprehensive model optimization, we recommend the add-on Optimization Costs/CO2 -Emission estimation.