- Design of members and sets of members for tension, compression, bending, shear, combined internal forces, and torsion

- Stability analysis of buckling and lateral-torsional buckling

- Automatic determination of critical buckling loads and critical buckling moments for general load applications and support conditions by means of a special FEA program (eigenvalue analysis) integrated in the module

- Alternative analytical calculation of the critical buckling moment for standard situations

- Optional application of discrete lateral supports to beams and continuous members

- Automatic cross-section classification (compact, noncompact, and slender)

- Serviceability limit state design (deflection)

- Cross-section optimization

- A wide range of available cross-sections, such as rolled I-sections; channel sections; T-sections; angles; rectangular and circular hollow sections; round bars; symmetrical and asymmetrical, parametric I-, T-, and angle sections; double angles

- Clearly arranged input and result windows

- Detailed result documentation including references to design equations of the used standard

- Various filter and sorting options of results, including result lists by member, cross-sections, and x-location, or by load case, load combination, and result combination

- Result table of member slenderness and governing internal forces

- Parts list with weight and solid specifications

- Seamless integration in RFEM/RSTAB

- Metric and imperial units

RF-/STEEL AISC | Features

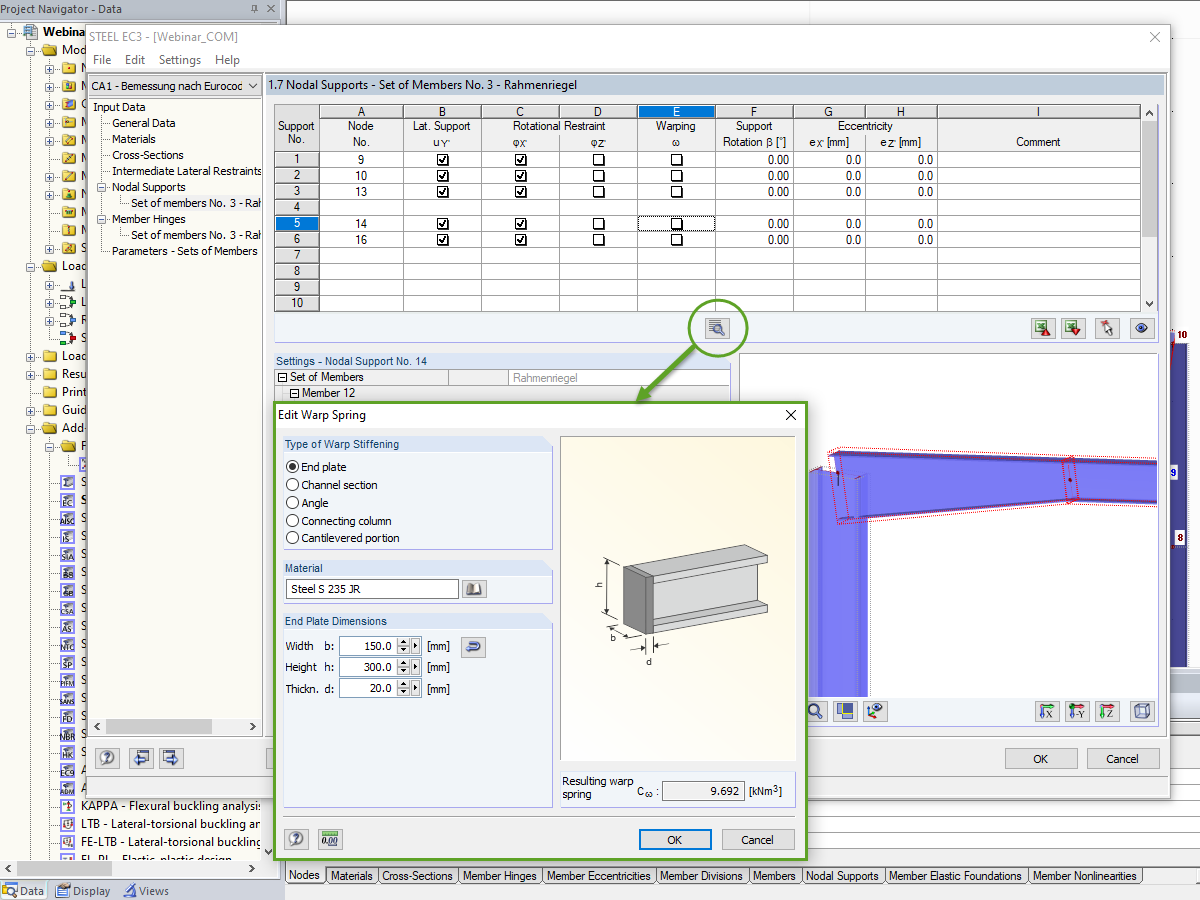

Due to the integrated RF-/STEEL Warping Torsion module extension, it is possible to perform the design according to Design Guide 9 in RF-/STEEL AISC.

The calculation is performed with 7 degrees of freedom according to the warping torsion theory and enables a realistic stability design, including consideration of torsion.

The determination of the critical buckling moment is carried out in RF-/STEEL AISC by using the eigenvalue solver which allows an exact determination of the critical buckling load.

The eigenvalue solver shows a display window of the eigenvalue graphics, which enables checking of the boundary conditions.

In STEEL AISC, it is possible to consider lateral intermediate supports at any location. For example, it is possible to stabilize only the upper flange.

Furthermore, user-defined lateral intermediate supports can be assigned; for example, single rotational springs and translational springs at any location at the cross-section.

The first result window shows the maximum design ratios with the corresponding design of each designed load case, load combination, or result combination.

The other result windows list all detailed results sorted by specific subject in extendable tree menus. All intermediate results along the members can be displayed at any location. In this way, you can easily retrace how the module has performed the individual designs.

The complete module data are part of the RFEM/RSTAB printout report. You can select the report contents and extent specifically for the individual designs.

In the Steel Joints add-on, I get high utilization ratios for preloaded bolts in the tension design. Where do these high utilization ratios come from and how can I evaluate the load-bearing reserves of the bolt?

How can treating a connection as fully rigid result in an uneconomical design?

.png?mw=350&hash=ee8eebbc3a9625027da40a29e64957e5f65cfede)

_1.jpg?mw=350&hash=ab2086621f4e50c8c8fb8f3c211a22bc246e0552)

.png?mw=600&hash=49b6a289915d28aa461360f7308b092631b1446e)