Topic:

Fire Resistance Design of Steel Components with Hot-Dip Galvanizing in RFEM 6 / RSTAB 9

Notes:

With the Steel Design add-on, you can design structural steel components in the event of fire using the simple design methods according to Eurocode 3. The component temperature at the time of the design check can be determined automatically according to the temperature-time curves specified in the standard. In addition to considering a cladding for fire protection, it is also possible for you to take account of the beneficial properties of hot-dip galvanization.

Description:

Hot-dip galvanizing of structural steel components is typically used as a measure for protection against corrosion. In addition, a surface that is hot-dip galvanized also has an advantageous effect on the fire resistance design. According to findings gathered in a research project at the Technical University of Munich in Germany, the emissivity of the steel surface is significantly reduced by hot-dip galvanization [1].

In a temperature range up to 500 °C, an emissivity of εm = 0.35 is recommended instead of εm = 0.7 assumed in EN 1993-1-2. These results have also been included in a German steel guideline, that is 027 of DASt (German Committee for Steel Construction). The incorporation into the next generation of Eurocodes is another aim.

The emissivity of the structural component's surface is an essential influencing parameter for the determination of the component temperature according to EN 1993-1-2. Depending on the fire exposure, the lower emissivity results in lower temperatures, and thus in a higher load-bearing capacity at the time of the design check. By applying hot-dip galvanization, it is often possible to achieve a fire resistance of R30 (fire exposure of 30 minutes) even without further fire protection measures.

Further information on this topic can be found on the website of the German Institute for Hot-Dip Galvanizing.

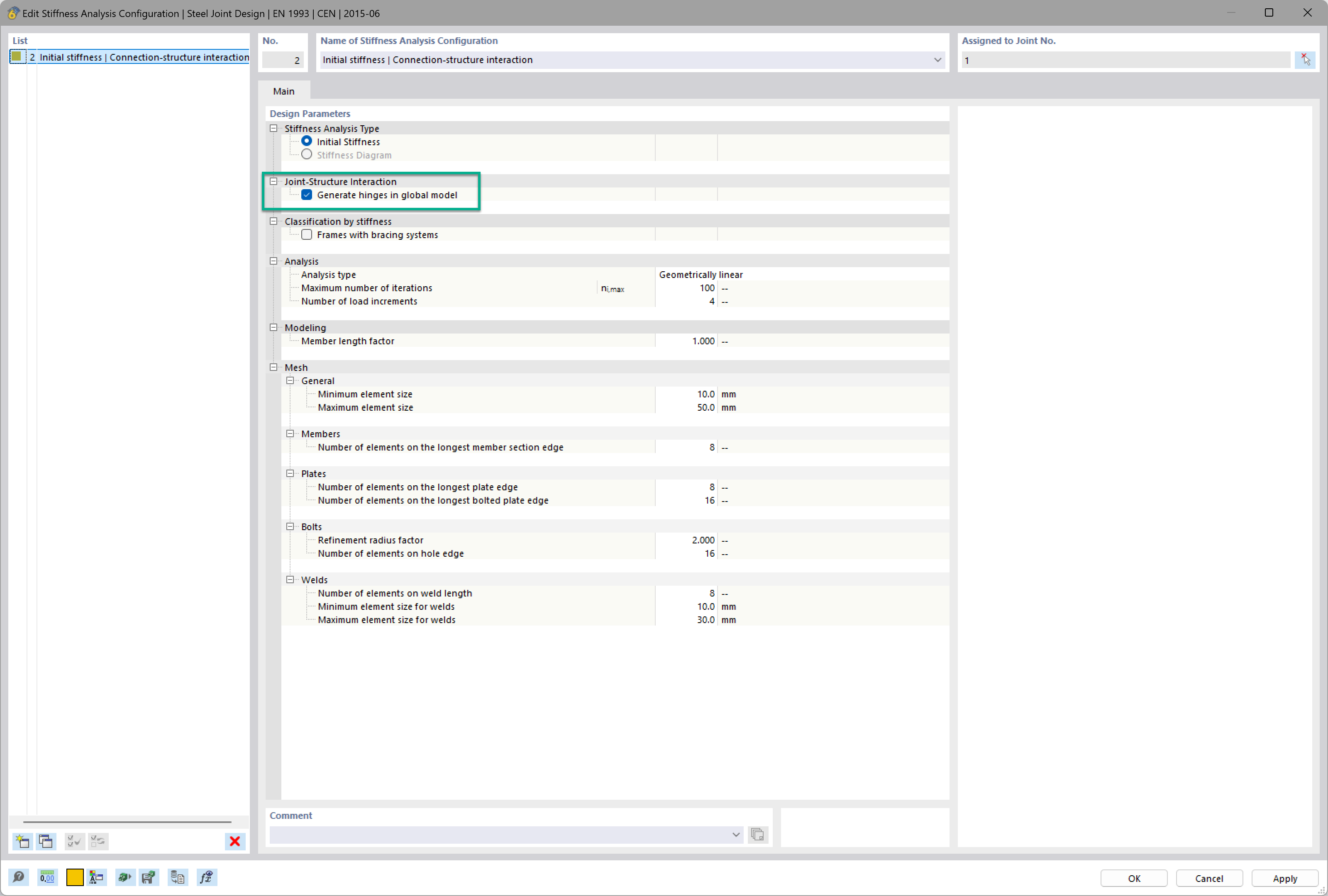

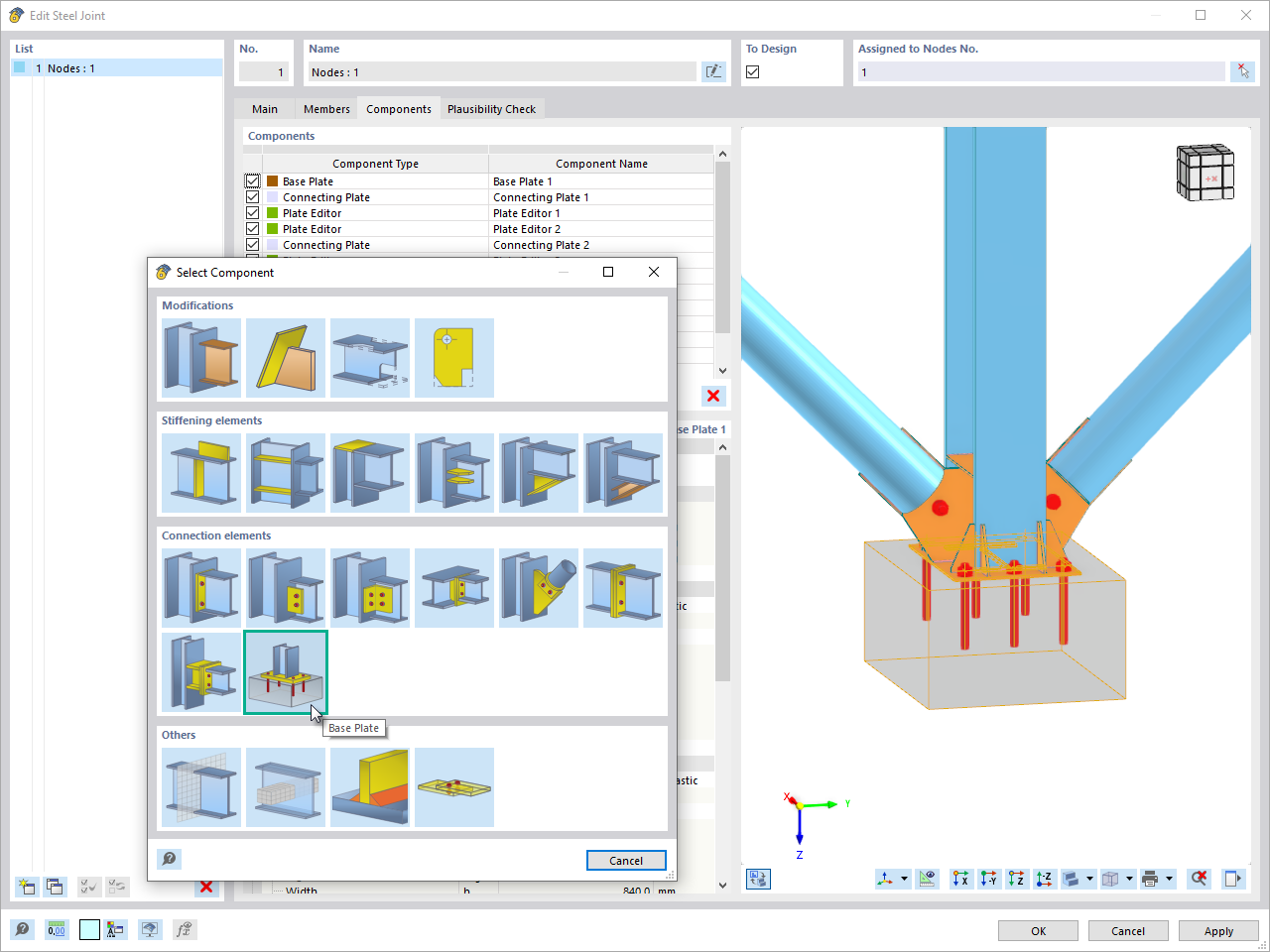

Determining Temperature at Design Time in Steel Design Add-on

Define the parameters for the fire resistance design of a member within the fire resistance configuration in the Steel Design add-on. To determine the relevant component temperature at the design check time in accordance with the analytical method, the corresponding temperature-time curve, the required time of fire resistance, and the fire exposure must be selected. You can adjust the coefficients used to determine the temperature in the 'Thermal actions for temperature analysis' section. As a default setting, the values according to EN 1993-1-2 are initially given. Activate the 'Galvanized surface of carbon steel member' check box to take into account the lower emissivity up to the component temperature of 500 °C.

The intermediate values for determining the component temperature are clearly listed in the design details of the fire resistance designs. In addition, the temperature-time diagram is available as a result for each member.

Fire Resistance Design in Steel Design Add-on

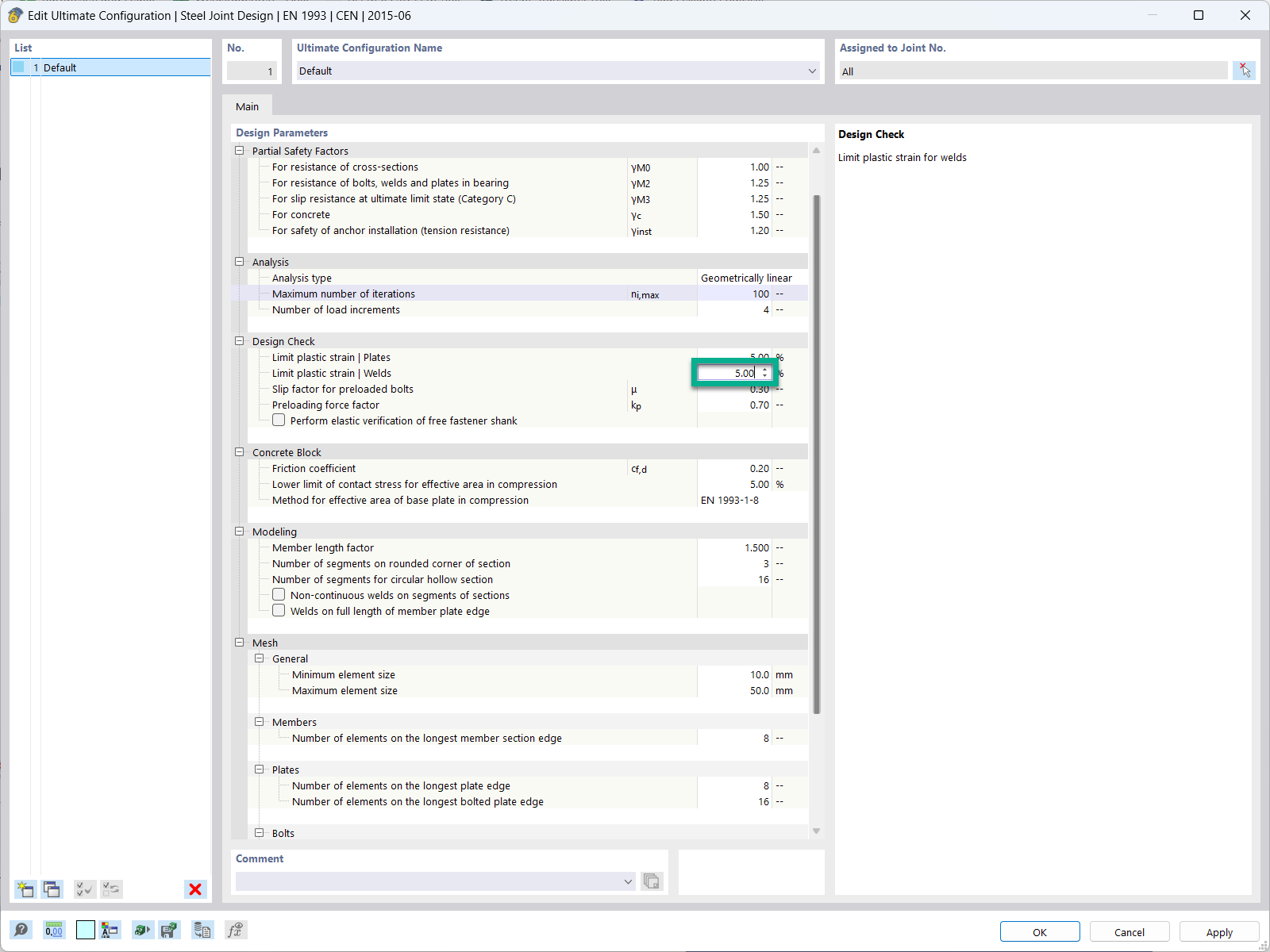

In the fire resistance design, the load case combination is carried out for the accidental design case. In comparison to the combination for the ultimate limit state, the partial safety as well as the combination factors are applied more favorably. Create another design situation of the 'Accidental - psi-2.1' type and activate it in the steel design.

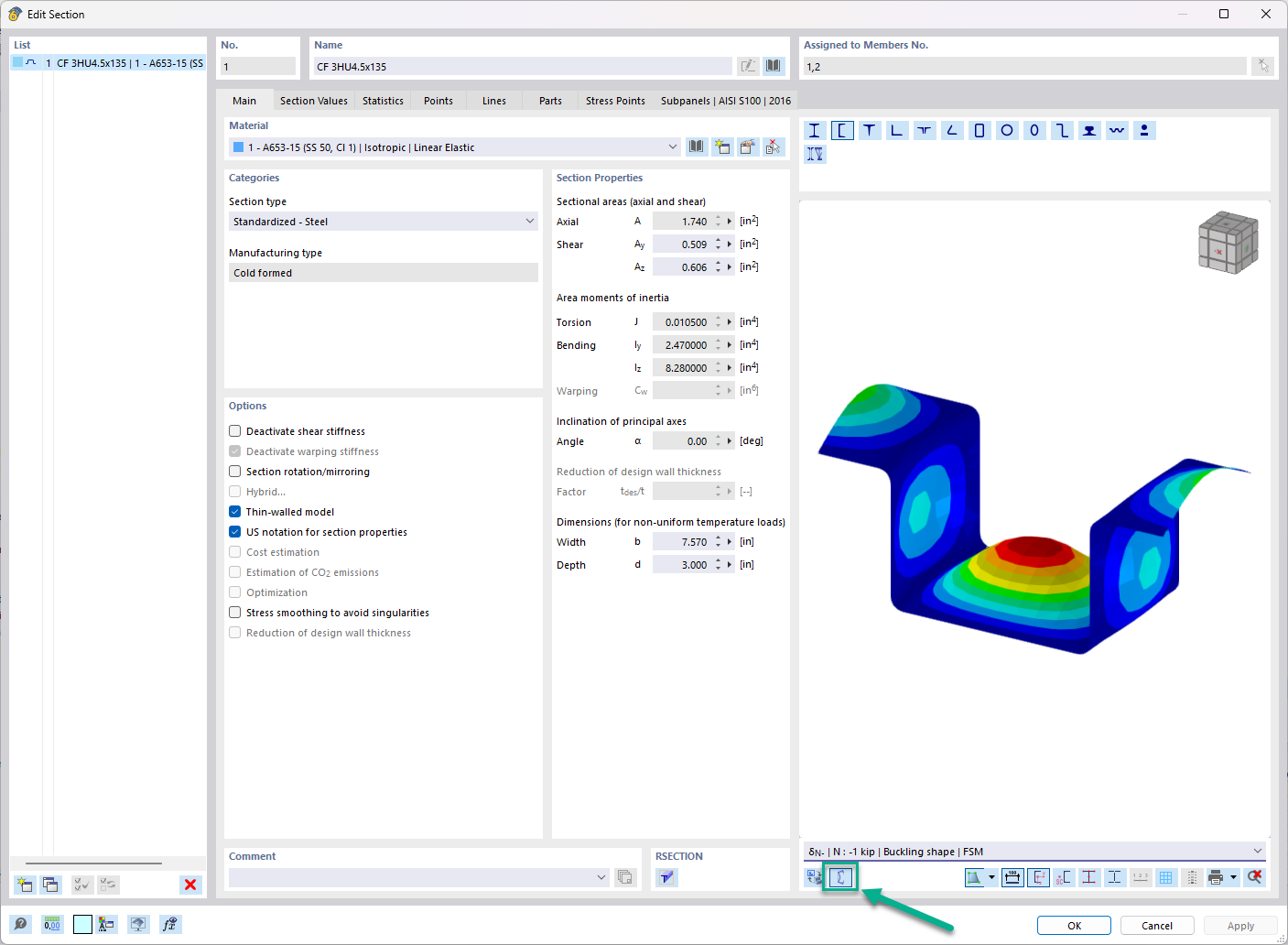

For this design situation, the component design checks are performed with the add-on according to EN 1993-1-2, Section 4.2.3. The first step is to determine the temperature as described above. This is followed by the design taking into account the temperature-related reduction factors according to the component temperature at the time of design check.

In the following example, a floor beam with fire exposure on three sides is analyzed. Due to the accidental design situation, the design value of the bending moment is roughly halved compared to the ULS. The load-bearing capacity in case of fire would therefore be given if the temperature-related decrease in strength at the design check time is less than 50%.

A fire exposure of 30 minutes (R30) results in a component temperature of 675 °C for a HEM 180 profile without the use of hot-dip galvanization. At such a temperature, only 41% of the load-bearing capacity is available for the cross-section design. Therefore, the design for the example beam is not fulfilled. Fire protection measures need to be provided or a larger cross-section would have to be selected.

With hot-dip galvanizing, the component temperature is only 567 °C, and 61% of the load-bearing capacity is still available at the design check time. This means that the design checks are fulfilled without any further fire protection measures. All relevant intermediate values and the formulas used for the design are listed in the design details.

More Videos:

► KB 001840 | Fire Resistance Design of Steel Components with Hot-Dip Galvanizing in RFEM...

.png?mw=350&hash=c6c25b135ffd26af9cd48d77813d2ba5853f936c)

_1.jpg?mw=350&hash=ab2086621f4e50c8c8fb8f3c211a22bc246e0552)

.png?mw=600&hash=49b6a289915d28aa461360f7308b092631b1446e)