Suspension glass bridge.

| 5 star | ||

| 4 star | ||

| 3 star | ||

| 2 star | ||

| 1 star |

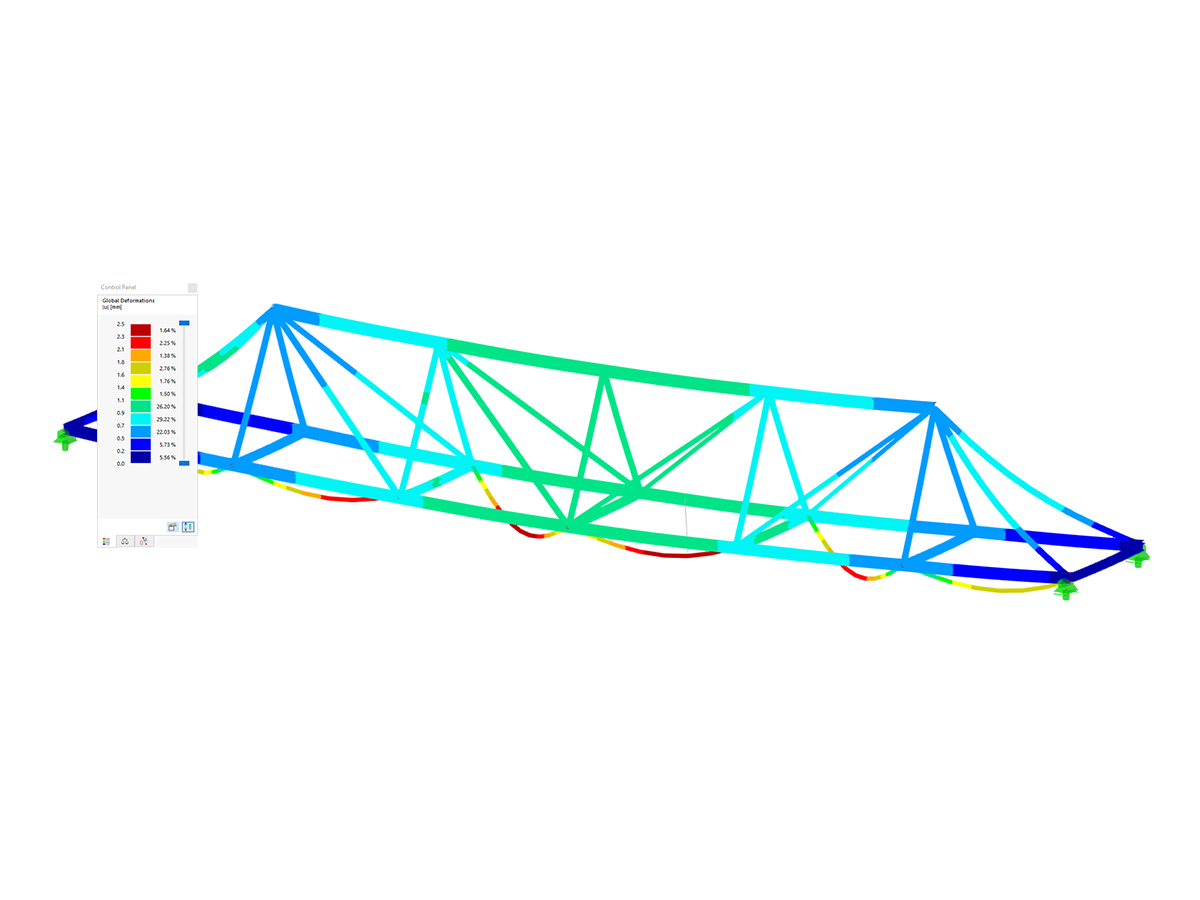

Suspension Bridge

| Number of Nodes | 292 |

| Number of Lines | 501 |

| Number of Members | 501 |

| Number of Surfaces | 70 |

| Number of Solids | 0 |

| Number of Load Cases | 8 |

| Number of Load Combinations | 58 |

| Number of Result Combinations | 1 |

| Total Weight | 127.987 tons |

| Dimensions (Metric) | 284.000 x 26.000 x 3.000 m |

| Dimensions (Imperial) | 931.76 x 85.3 x 9.84 feet |

You can download this structural model to use it for training purposes or for your projects. However, we do not assume any guarantee or liability for the accuracy or completeness of the model.

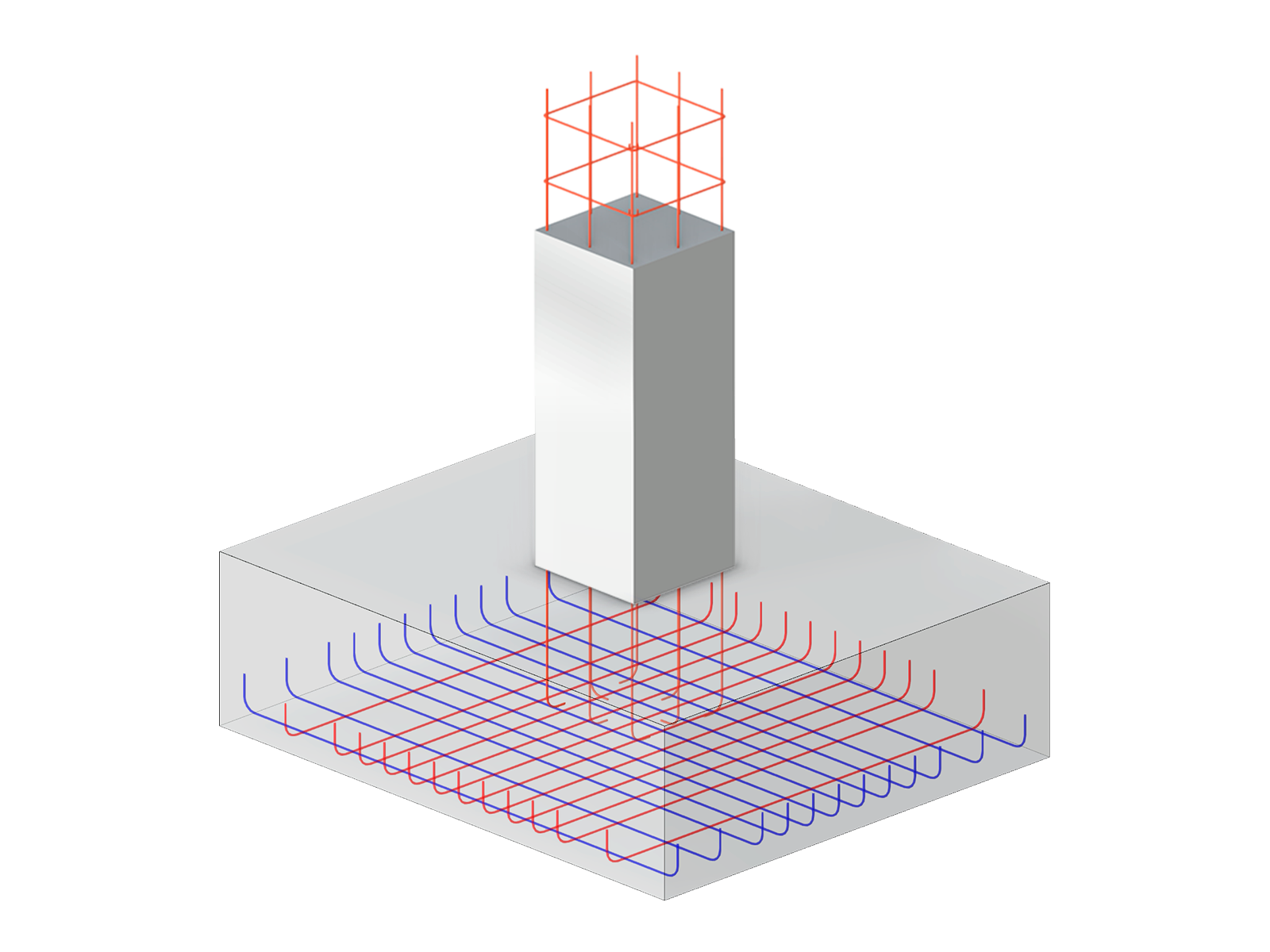

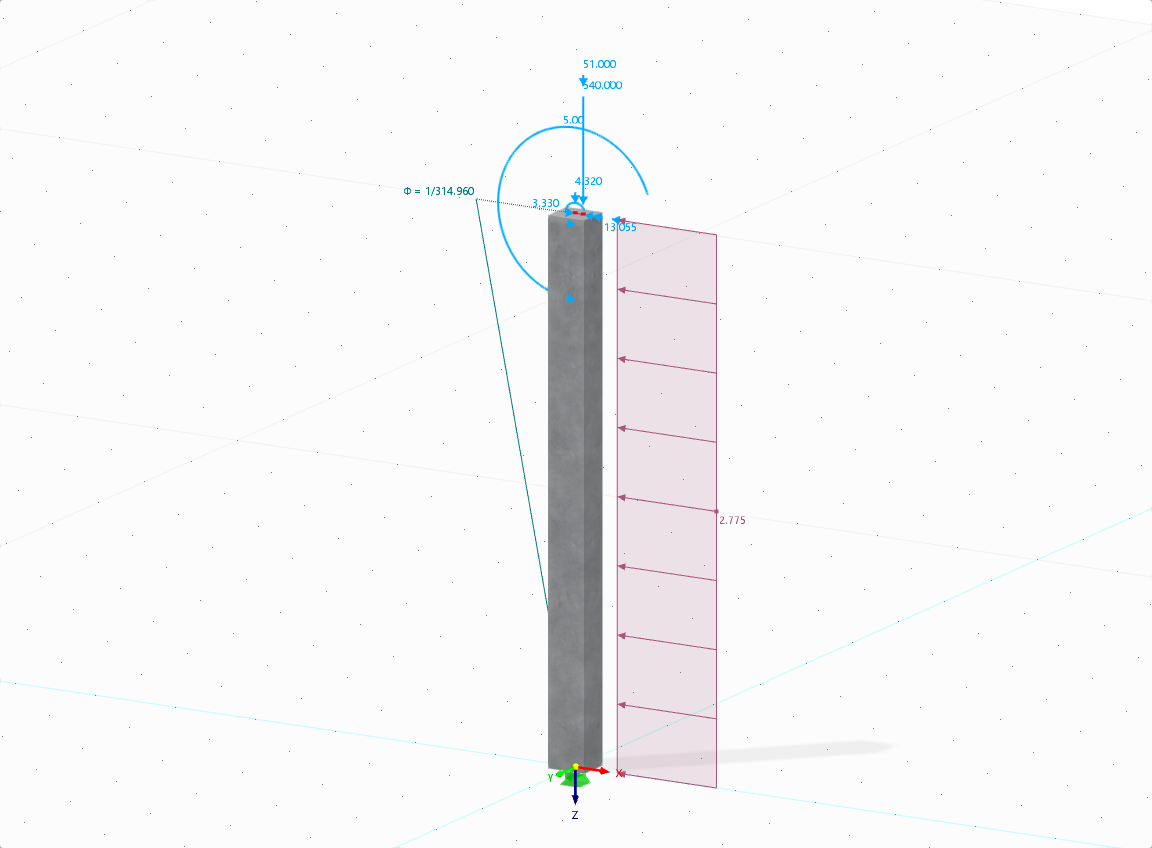

The aim of this technical article is to perform a design according to the general design method of Eurocode 2, using the example of a slender reinforced concrete column.

The modal relevance factor (MRF) can help you to assess to which extent specific elements participate in a specific mode shape. The calculation is based on the relative elastic deformation energy of each individual member.

The MRF can be used to distinguish between local and global mode shapes. If multiple individual members show significant MRFs (for example, > 20%), the instability of the entire structure or a substructure is very likely. On the other hand, if the sum of all MRFs for an eigenmode is around 100%, a local stability phenomenon (for example, buckling of a single bar) can be expected.

Furthermore, the MRF can be used to determine critical loads and equivalent buckling lengths of certain members (for example, for stability design). Mode shapes for which a specific member has small MRF values (for example, < 20%) can be neglected in this context.

The MRF is displayed by mode shape in the result table under Stability Analysis → Results by Members → Effective Lengths and Critical Loads.

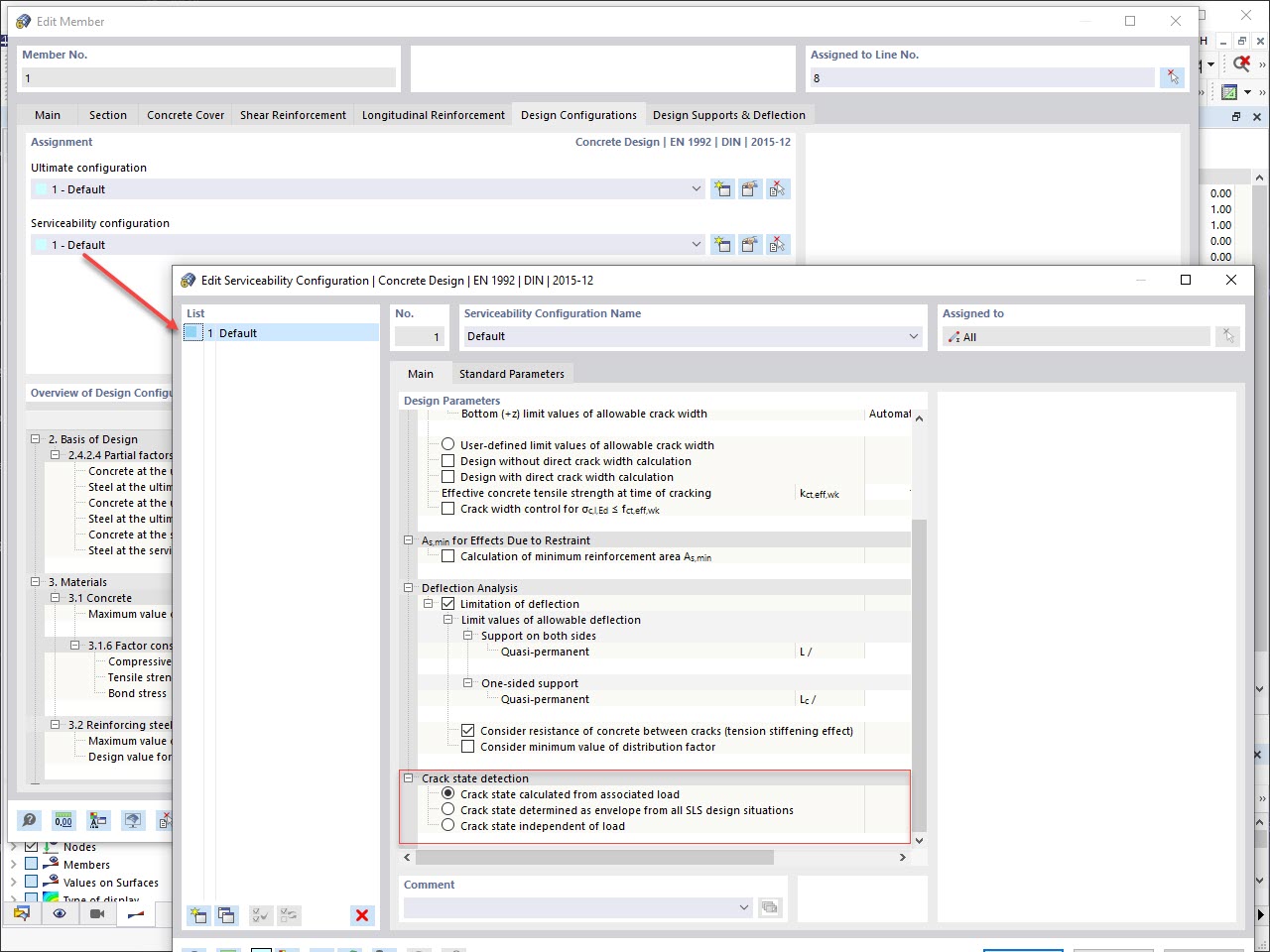

Various design parameters of the cross-sections can be adjusted in the serviceability limit state configuration. The applied cross-section condition for the deformation and crack width analysis can be controlled there.

For this, the following settings can be activated:

- Crack state calculated from associated load

- Crack state determined as an envelope from all SLS design situations

- Cracked state of cross-section - independent of load

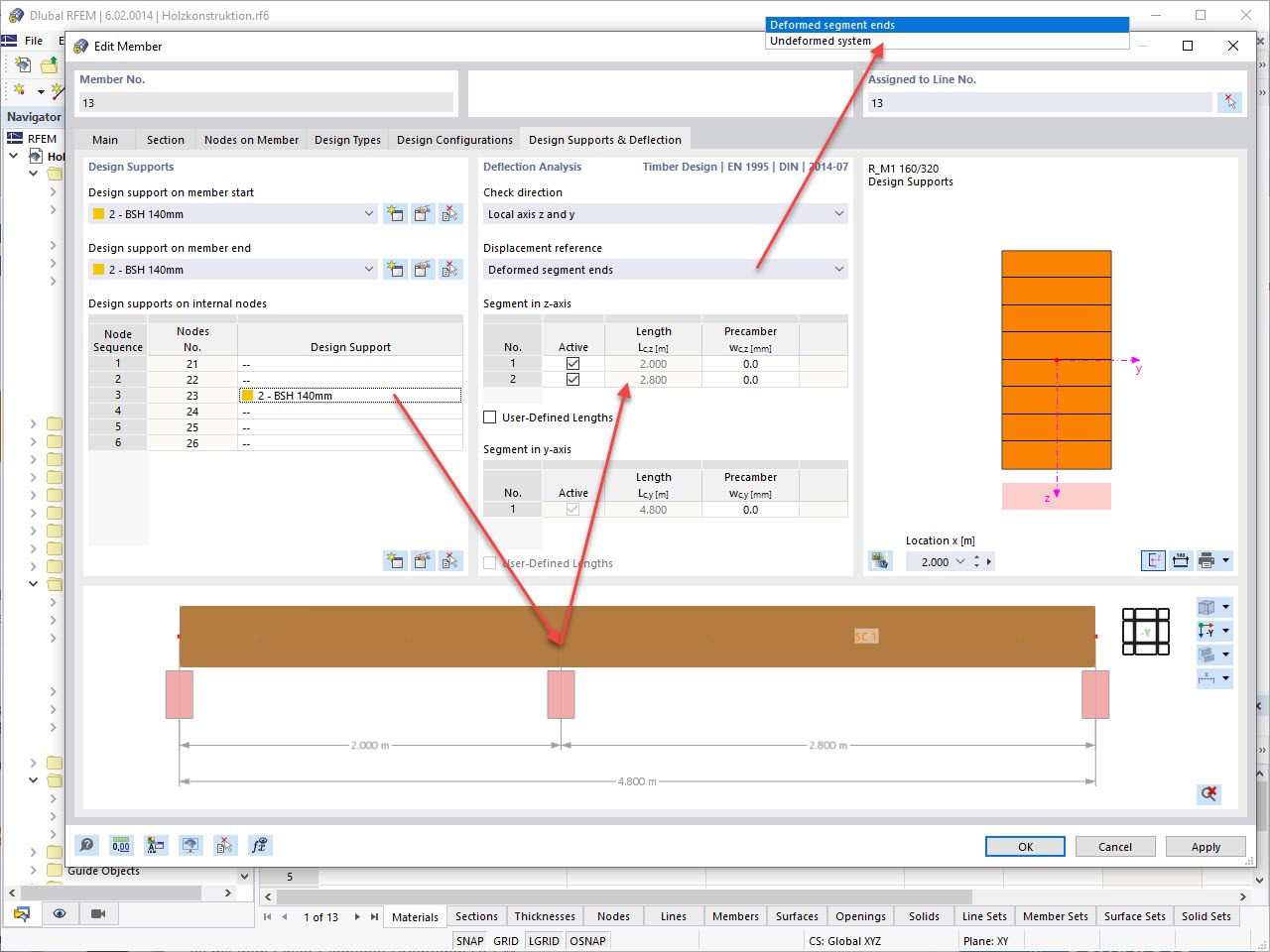

In the "Deflection and Design Support" tab under "Edit Member", the members can be clearly segmented using optimized input windows. Depending on the supports, the deformation limits for cantilever beams or single-span beams are used automatically.

By defining the design support in the corresponding direction at the member start, member end, and intermediate nodes, the program automatically recognizes the segments and segment lengths to which the allowable deformation is related. It also automatically detects whether it is a beam or a cantilever due to the defined design supports. The manual assignment, as in the previous versions (RFEM 5), is no longer necessary.

The "User-Defined Lengths" option allows you to modify the reference lengths in the table. The corresponding segment length is always used by default. If the reference length deviates from the segment length (for example, in the case of curved members), it can be adjusted.

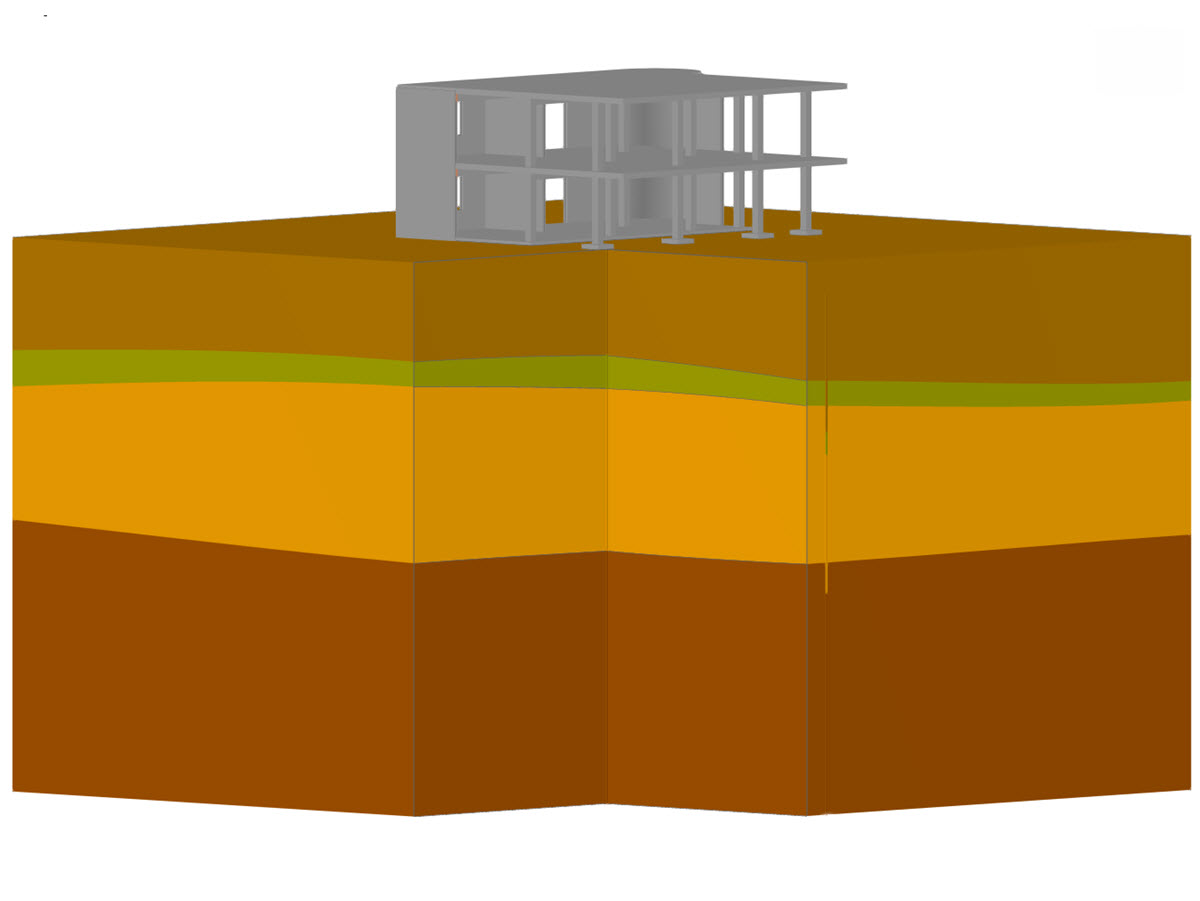

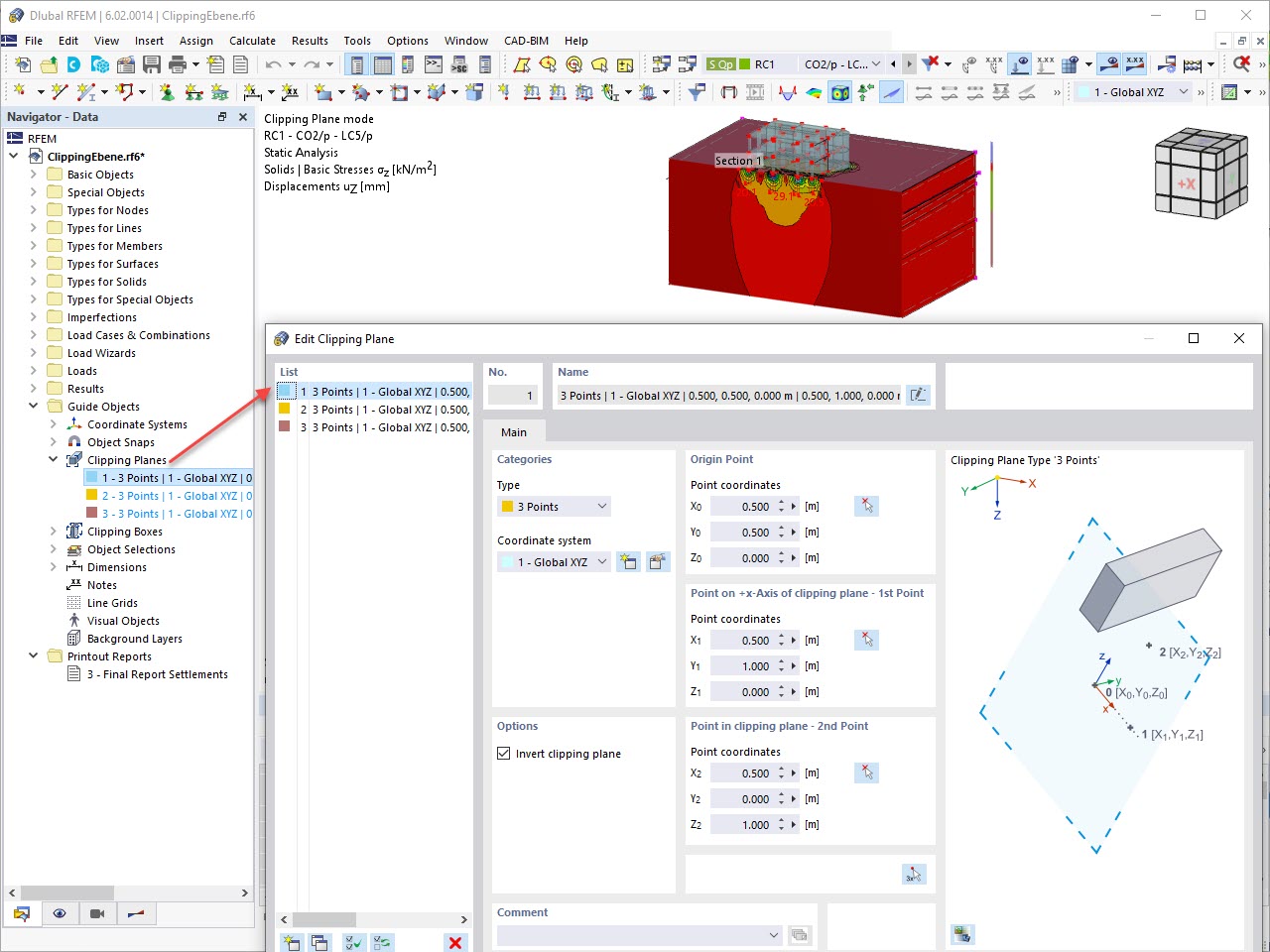

This feature also contributes to the clearly-arranged display of your results. Clipping planes are intersecting planes that you can place freely throughout the model. The zone in front of or behind the plane is consequently hidden in the display. This way, you can clearly and simply show the results in an intersection or a solid, for example.

Why is the effective depth different with the effective depth used in shear checks?

Can I optimize parametric cross-sections?