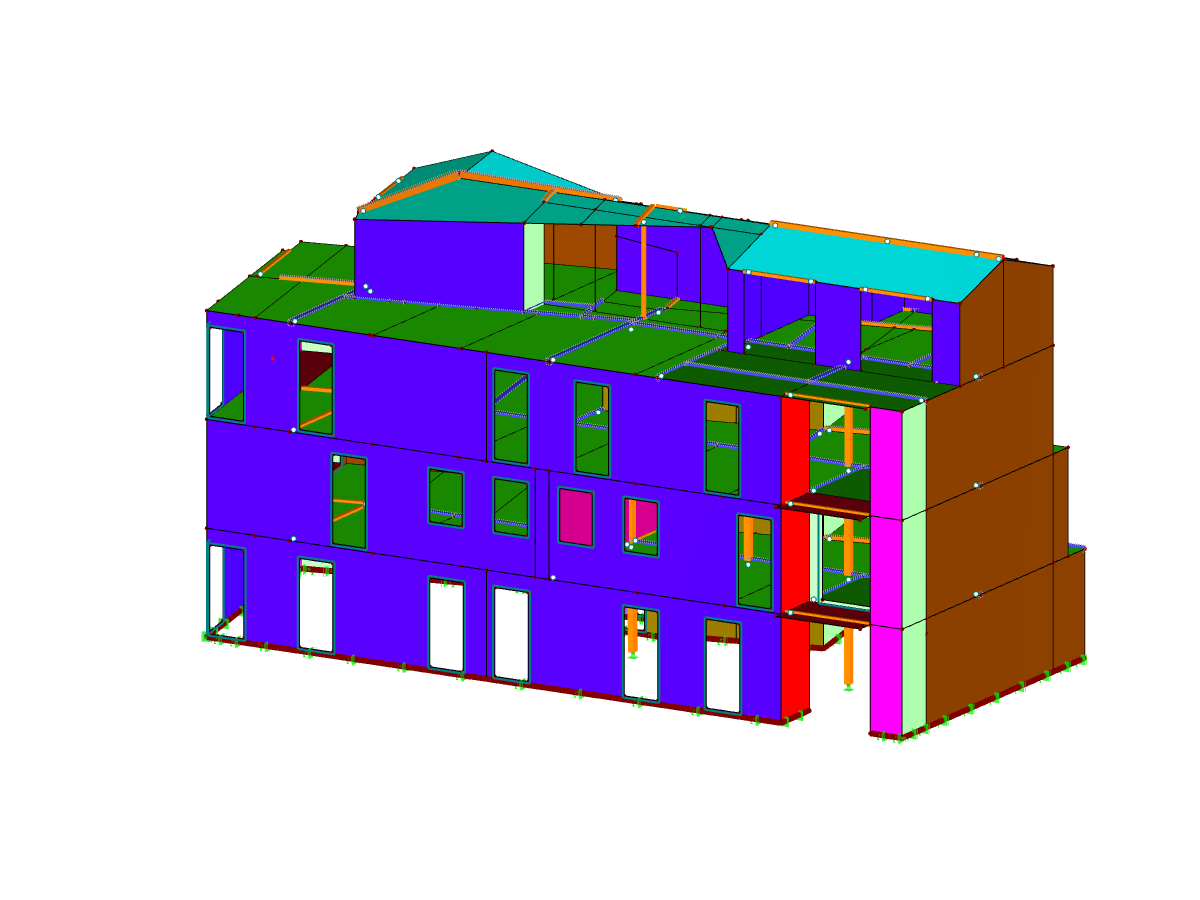

Structural Model

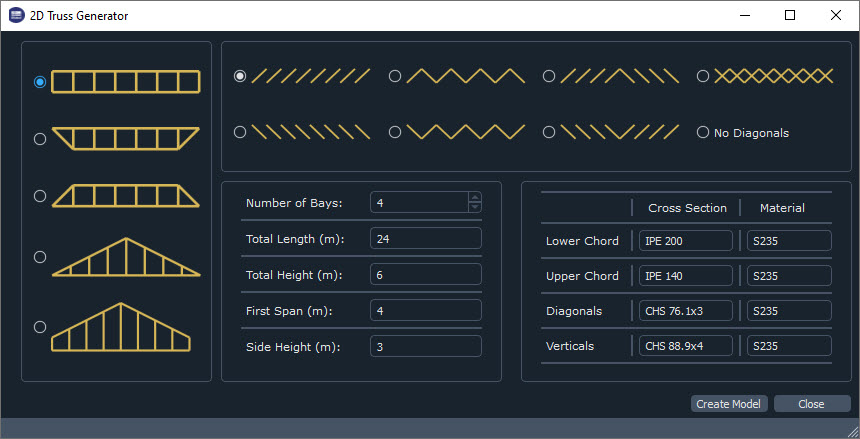

For the system shown in Image 01, the truss members should be analyzed for lateral buckling. In the roof plane, six truss members are available as parallel beams with a length of 18 m and two stiffening bracings. The beams on the gable sides are supported by columns and are not considered for the calculation. A design load qd of 10 kN/m acts on the truss members.

Model Data

| L | 18 | m | Beam length |

| b | 120 | mm | Beam width |

| h | 1.200 | mm | Beam height |

| GL24h | - | - | Material according to EN 14080 |

| Iz | 172.800.000 | mm4 | Moment of inertia |

| IT | 647.654.753 | mm4 | Torsion moment of inertia |

| qd | 10 | kN/m | Design load |

| az | 600 | mm | Load position |

| e | 600 | mm | Foundation position |

Note: Even if the following equations for E and G do not explicitly refer to the 5%-quantiles in the index, they have been taken into account accordingly.

Single-Span Beam with Lateral and Torsional Restraint Without Intermediate Supports

For the sake of completeness, the truss member is analyzed first, without lateral supports (see Image 02). The equivalent member length results from a load application on the upper side of the truss with a1 = 1.13 and a2 = 1.44 as follows:

|

lef |

Ersatzstablänge |

|

L |

Trägerlänge, Abstand der seitlichen Halterung |

|

a1,a2 |

Kippbeiwerte |

|

az |

Abstand des Lastangriffs vom Schubmittelpunkt |

|

E0,05 |

5 % Quantile des Elastizitätsmoduls |

|

G0,05 |

5 % Quantile des Schubmoduls |

|

Iz |

Trägheitsmoment um die schwache Achse |

|

IT |

Torsionsträgheitsmoment |

lef = 17.79 m

The critical bending moment can then be calculated as follows:

|

Mcrit |

Kritisches Biegemoment |

|

E0,05 |

5 % Quantile des Elastizitätsmoduls |

|

G0,05 |

5 % Quantile des Schubmoduls |

|

Iz |

Trägheitsmoment um die schwache Achse |

|

IT |

Torsionsträgheitsmoment |

|

lef |

Ersatzstablänge |

Mcrit = 134.52 kNm

These examples do without an increase of the product of the 5%-quantiles of the stiffness properties due to the homogenization of beams made of glued-laminated timber.

The bending moment acting on the trusses results as follows:

Md = 405.00 kNm

The eigenvalue analysis with the RF-/FE-LTB add-on module provides a critical buckling load factor of 0.3334 as a result. This results in the critical bending moment

Mcrit = 0.3334 ⋅ 405 kNm = 135.03 kNm

and is thus identical to the result of the analytical solution.

As was to be expected for this unsupported, slender truss member, the acting bending moment is greater (by a factor of 3) than the critical bending moment, and the truss is thus not sufficiently restrained against lateral buckling. However, a bracing should counteract, which is now considered for the calculation.

Single-Span Beam with Lateral and Torsional Restraint with Rigid Intermediate Supports

If the stiffening bracing is stiff enough, the spacing between the lateral supports (for example, by purlins) is often used as an equivalent member length for the lateral buckling analysis. This procedure was described in the previous article Lateral-Torsional Buckling in Timber Construction | Examples 1.

Thus, 2.25 m is used as L. For a1 = 1.00 and a2 = 0.00, this follows:

|

lef |

Ersatzstablänge |

|

L |

Trägerlänge, Abstand der seitlichen Halterung |

|

a1,a2 |

Kippbeiwerte |

|

az |

Abstand des Lastangriffs vom Schubmittelpunkt |

|

E0,05 |

5 % Quantile des Elastizitätsmoduls |

|

G0,05 |

5 % Quantile des Schubmoduls |

|

Iz |

Trägheitsmoment um die schwache Achse |

|

IT |

Torsionsträgheitsmoment |

lef = 2.25 m

The following results for the critical bending moment:

|

Mcrit |

Kritisches Biegemoment |

|

E0,05 |

5 % Quantile des Elastizitätsmoduls |

|

G0,05 |

5 % Quantile des Schubmoduls |

|

Iz |

Trägheitsmoment um die schwache Achse |

|

IT |

Torsionsträgheitsmoment |

|

lef |

Ersatzstablänge |

Mcrit = 1,063.51 kNm

Since the bending moment acting on the beam is smaller than the critical bending moment, the beam is not endangered by lateral buckling under the assumption of rigid intermediate supports.

The eigenvalue analysis with the RF-/FE-LTB add-on module provides a critical buckling load factor of 2.7815 as a result. This results in the critical bending moment

Mcrit = 2.7815 ⋅ 405 kNm = 1,126.50 kNm

Single-Span Beam with Lateral and Torsional Restraint and Member Elastic Foundation

As described in Lateral-Torsional Buckling in Timber Construction | Theory, the determination of the equivalent member length for members on elastic foundation is extended by the factors α and β in [1].

Thus, it is possible to consider the shear stiffness of a stiffening bracing for the lateral buckling of the truss members. The bracing's shear stiffness can be determined, for example, according to [2], Figure 6.34. As can be seen from the above, it depends on the type of bracing, the strain stiffness of diagonals and posts, the diagonals' inclination, and the ductility of the fasteners. For the stiffening bracing shown in Image 01, the shear stiffness results in:

|

sid |

Ideelle Schubsteifigkeit des Aussteifungsverbandes |

|

ED |

5 % Quantile des Elastizitätsmoduls der Diagonalen |

|

AD |

Querschnittsfläche der Diagonalen |

|

α |

Winkel zwischen der Diagonalen und der Gurte |

Here, ED is the diagonals' modulus of elasticity and AD is their cross-sectional area. However, the equation above does not include the ductility of the diagonals' fasteners. This and the member elongation of the diagonals can be considered by means of a notional cross-section area AD'. What follows is this:

|

sid |

Ideelle Schubsteifigkeit des Aussteifungsverbandes |

|

ED |

5 % Quantile des Elastizitätsmoduls der Diagonalen |

|

AD' |

Fiktive Querschnittsfläche der Diagonalen |

|

α |

Winkel zwischen der Diagonalen und der Gurte |

where

|

AD' |

Fiktive Querschnittsfläche der Diagonalen |

|

AD |

Querschnittsfläche der Diagonalen |

|

ED |

5 % Quantile des Elastizitätsmoduls der Diagonalen |

|

LD |

Länge der Diagonalen |

|

Kser |

Verschiebungsmodul der Verbindung |

The diagonals have a dimension of w/h = 120/200 mm and a length LD of 4.59 m. The slip modulus of the connection on each side of the diagonals should be 110,000 N/mm.

The ideal area is, accordingly,

AD' = 12,548 mm²

and thus, the shear stiffness of a bracing with a diagonals-to-chord angle of 60.64 ° is

|

sid |

Ideelle Schubsteifigkeit des Aussteifungsverbandes |

|

ED |

5 % Quantile des Elastizitätsmoduls der Diagonalen |

|

AD' |

Fiktive Querschnittsfläche der Diagonalen |

|

α |

Winkel zwischen der Diagonalen und der Gurte |

sid = 44,864 kN

The member foundation per bracing can be converted according to [2], Formula 7.291 as follows:

|

Ky' |

Elastische Stabbettung pro Verband |

|

sid |

Ideelle Schubsteifigkeit des Aussteifungsverbandes |

|

L |

Länge des Verbandes |

For two bracings and six truss members, the following spring constant is available per truss:

|

Ky |

Elastische Stabbettung pro Binder |

|

Ky' |

Elastische Stabbettung pro Verband |

Ky = 455.6 kN/m² = 0.456 N/mm²

Provided that KG = ∞, Kθ = 0, Ky = 0.456 N/mm², e = 600 mm, a1 = 1.13, and a2 = 1.44, the equivalent member length results in:

|

lef |

Ersatzstablänge |

|

L |

Trägerlänge, Abstand der seitlichen Halterung |

|

a1,a2 |

Kippbeiwerte |

|

az |

Abstand des Lastangriffs vom Schubmittelpunkt |

|

E0,05 |

5 % Quantile des Elastizitätsmoduls |

|

G0,05 |

5 % Quantile des Schubmoduls |

|

Iz |

Trägheitsmoment um die schwache Achse |

|

IT |

Torsionsträgheitsmoment |

|

α, β |

Beiwerte zur Berücksichtigung einer Stabbettung |

lef = 0.13

Thus, the critical bending moment results in an unrealistic value of:

|

Mcrit |

Kritisches Biegemoment |

|

E0,05 |

5 % Quantile des Elastizitätsmoduls |

|

G0,05 |

5 % Quantile des Schubmoduls |

|

Iz |

Trägheitsmoment um die schwache Achse |

|

IT |

Torsionsträgheitsmoment |

|

lef |

Ersatzstablänge |

Mcrit = 18,482.84 kNm

A value similar to the system with rigid intermediate supports would be expected. As described in Lateral-Torsional Buckling in Timber Construction | Theory, the application of the extended formula with α and β is limited in its application.

Strictly speaking, it is only valid if there is a deflection in a large sinusoidal arc. In other words, if the foundation is very soft. This is no longer given in this example. Multi-wave eigenfunctions, leading to a small critical buckling load for any larger spring constant, are not included in the aforesaid equation, since it is based on monomial sinus approaches.

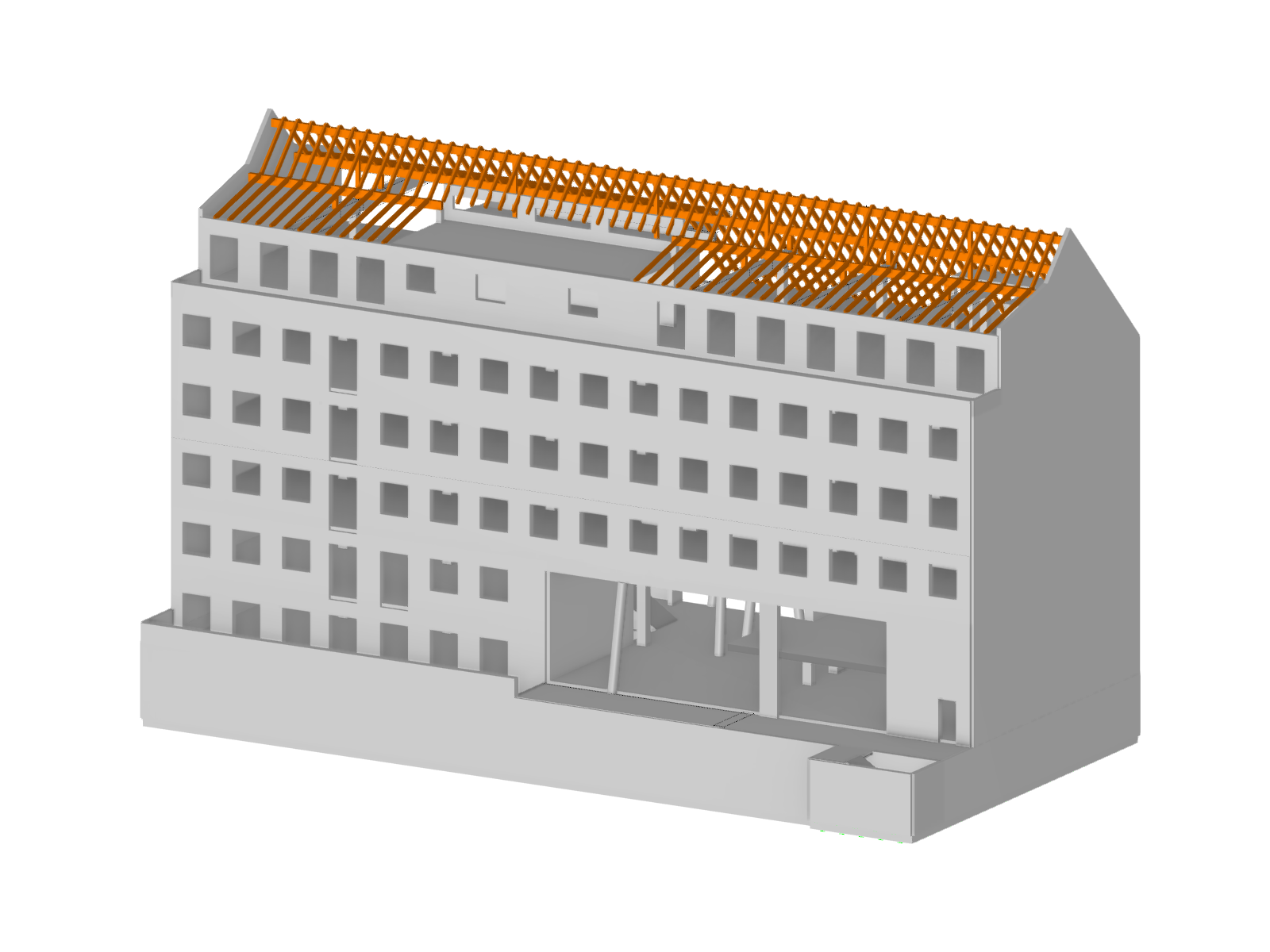

As you can see in Image 07, a multi-wave eigenvector results from the eigenvalue analysis.

In this case, the method derived by Prof. Dr. Heinrich Kreuzinger (2020) can be applied. The critical bending moment is calculated as follows:

|

Mcrit |

Kritisches Biegemoment |

|

az |

Abstand des Lastangriffs vom Schubmittelpunkt |

|

e |

Abstand der Stabbettung vom Schubmittelpunkt |

|

Ky |

elastische Stabbettung pro Binder |

|

L |

Trägerlänge |

|

n |

n-te Eigenlösung |

|

E0,05 |

5 % Quantile des Elastizitätsmoduls |

|

Iz |

Trägheitsmoment um die schwache Achse |

|

G0,05 |

5 %-Quantile des Schubmoduls |

|

IT |

Torsionsträgheitsmoment |

The constant n denotes the 1st, 2nd, 3rd … eigensolution. Thus, several eigensolutions have to be analyzed, and the smallest critical bending moment then governs. The following critical bending moments are the result for n = 1…30.

| n | Mcrit [kNm] | n | Mcrit[kNm] |

|---|---|---|---|

| 1 | 9,523.25 | 16 | 2,214.63 |

| 2 | 4,281.26 | 17 | 2,339.17 |

| 3 | 2,294.32 | 18 | 2,464.92 |

| 4 | 1,605.56 | 19 | 2,591.63 |

| 5 | 1,354.68 | 20 | 2,719.14 |

| 6 | 1,282.70 | 21 | 2,847.30 |

| 7 | 1,294.12 | 22 | 2,976.00 |

| 8 | 1,348.81 | 23 | 3,105.16 |

| 9 | 1,428.05 | 24 | 3,234.71 |

| 10 | 1,522.29 | 25 | 3,364.60 |

| 11 | 1,626.24 | 26 | 3,494.77 |

| 12 | 1,736.77 | 27 | 3,625.20 |

| 13 | 1,851.94 | 28 | 3,755.84 |

| 14 | 1,970.50 | 29 | 3,886.67 |

| 15 | 2,091.60 | 30 | 4,017.68 |

Mcrit becomes minimal for n = 6 and is about 1,282.70 kNm.

The eigenvalue solution from the RF-/FE-LTB add-on module (see Image 07) results in:

Mcrit = 3.4376 ⋅ 405 kNm = 1,397.25 kNm

Both results match very well. However, the analytical solution is on the safe side, as this method is based on a constant bending moment distribution. Then, a critical load qcrit is assigned to the constant critical bending moment Mcrit.

Since the member foundation in this example is regarded as very stiff and constantly distributed over the truss member length, critical bending moments occur that are slightly higher than for the rigid single supports.

According to [3], Chapter 9.2.5.3 (2), stiffening bracings must be stiff enough so that they do not exceed the horizontal deflection of L/500. The calculation must be carried out with the design values of the stiffnesses (see [1], Chapter NCI to 9.2.5.3).

For kcrit = 0.195, H = 5 m and qp = 0.65 kN/m² as gust velocity pressure, the following loads result (see [3], Chapter 9.2.5.3):

|

Nd |

Stabilisierungskraft für den Druckgurt |

|

kcrit |

Kippbeiwert |

|

Md |

Bemessungsmoment |

|

h |

Trägerhöhe |

Nd = (1 - 0.195) ⋅ 405 / 1.2 = 271.68 kN

|

qd |

Aussteifungslast |

|

n |

Anzahl der Binder |

|

L |

Trägerlänge |

|

kf,3 |

Modifikationsbeiwert für den Aussteifungswiderstand |

qd = 2.76 kN/m

|

qd,Wind |

Bemessungslast aus Wind |

|

γQ |

Teilsicherheitsbeiwert für veränderliche Einwirkung |

|

cpe |

Außendruckbeiwert |

|

qp |

Böengeschwindigkeitsdruck |

|

h |

Höhe des Gebäudes |

qd,wind = 1.5 ⋅ (0.7 + 0.3) ⋅ 0.65 ⋅ 5 / 2 = 2.44 kN/m

The deformation of the stiffening bracing is shown in Image 08. The loads were divided in half because there are two stiffening bracings.

The allowable deformation is:

The result confirms the assumption of a very stiff bracing and is consistent with the almost identical critical bending moments of the system with rigid intermediate supports and the one with elastic member foundation.

Conclusion

It was shown which possibilities in timber construction can be used to analyze the lateral buckling of bending beams. For common methods, it is important to ensure that the stiffening bracings are stiff enough to accept rigid supports. Options have been shown in this article for cases when this assumption does not apply. Basically, the bending beams and the stiffening bracings have to be designed for their load-bearing capacity and serviceability according to the corresponding standard. However, this is beyond the scope of this article.

.png?mw=600&hash=49b6a289915d28aa461360f7308b092631b1446e)