The elastic deformations of a structural component due to a load are based on Hooke's law, which describes a linear stress-strain relation. They are reversible: After the load is removed, the component returns to its original shape. However, plastic deformations lead to irreversible deformations. The plastic strains are usually considerably larger than the elastic deformations. When ductile materials such as steel are subjected to plastic stresses, yielding effects occur whereby the increase in deformation is accompanied by hardening. They lead to permanent deformations - and in extreme cases, to the destruction of the structural component.

KB 001651 | Plastic Analysis with RFEM

The limit stresses in RF‑/STEEL can be user-defined for each thickness range.

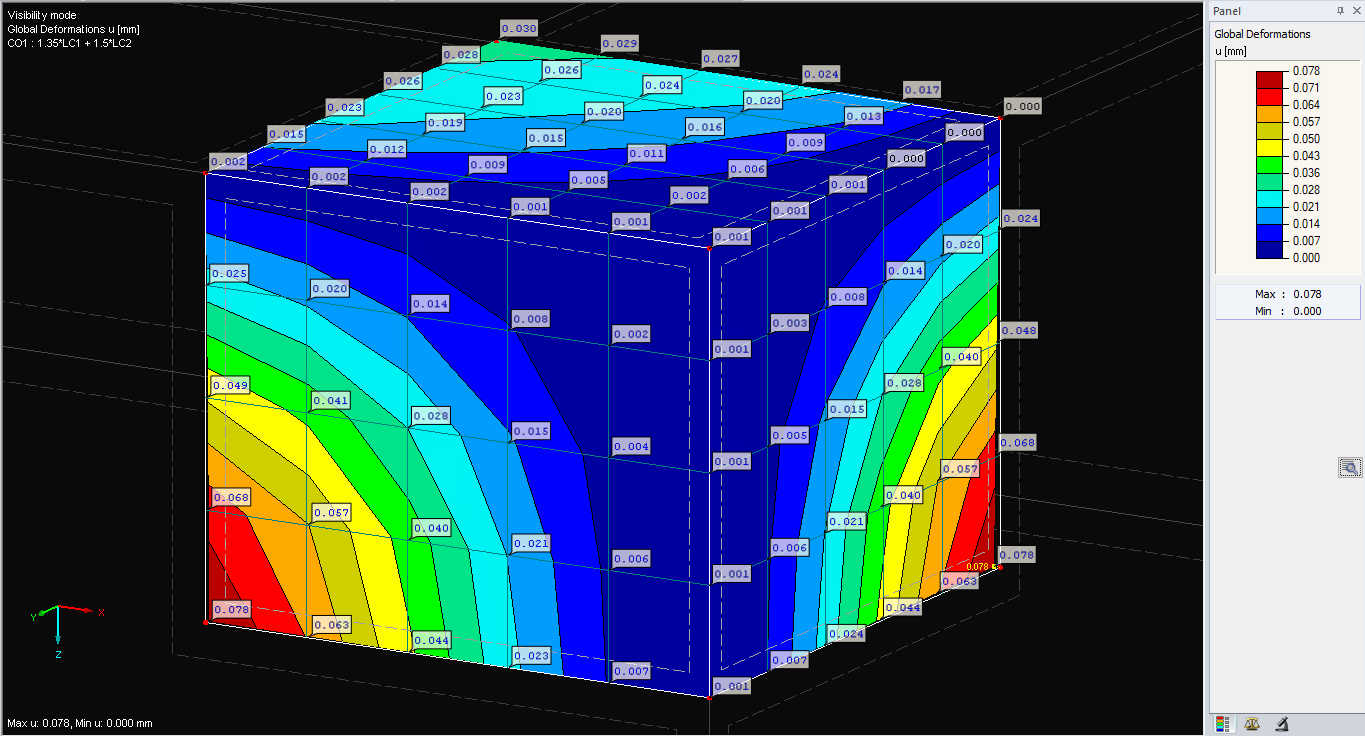

The deformations of the FE nodes are always the first result of an FE calculation. It is possible to calculate strains, internal forces, and stresses based on these deformations and the stiffness of the elements.

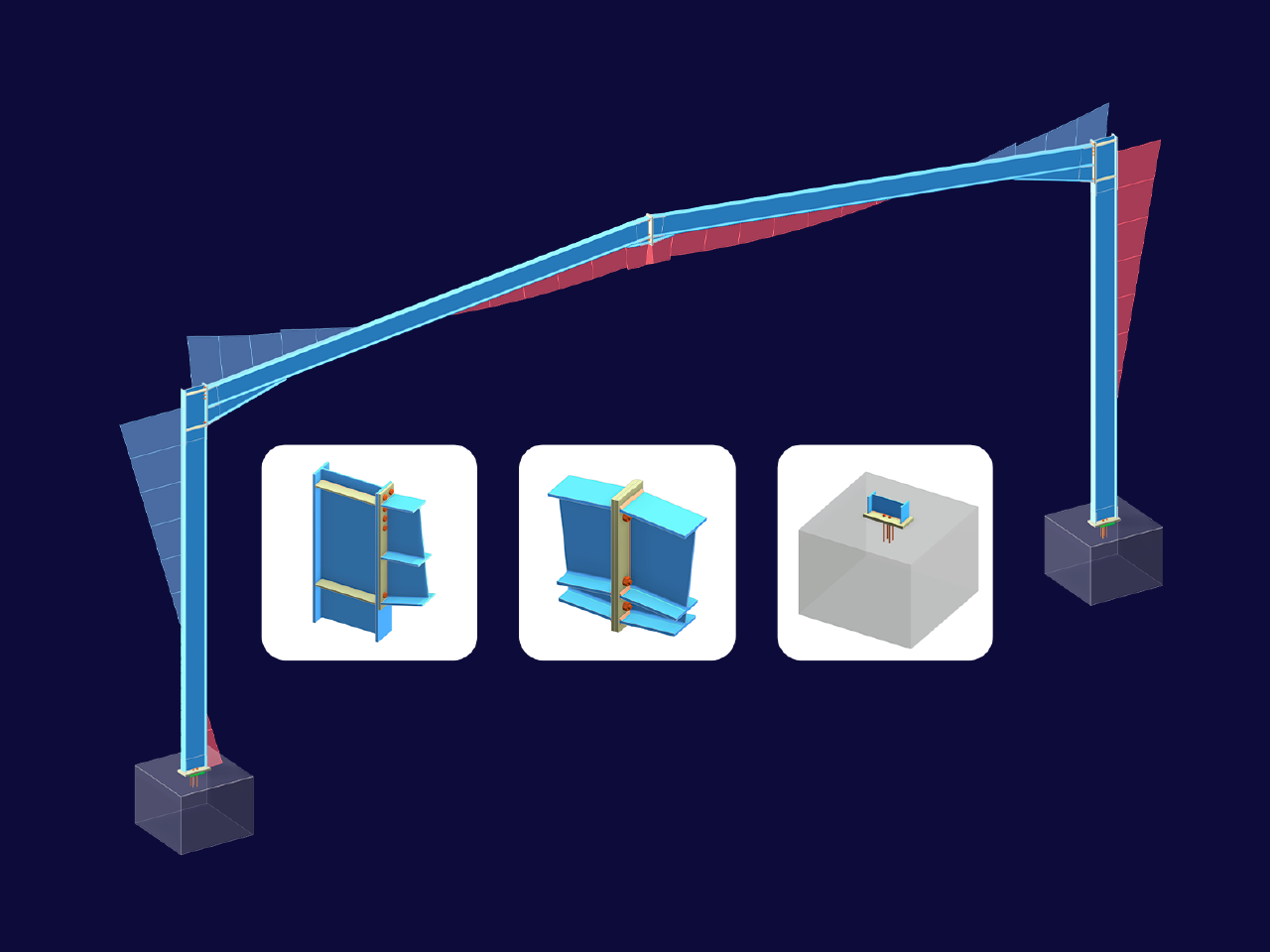

This article explores the importance of considering joint-structure interaction in modeling and design and how to do it in RFEM 6.

.png?mw=512&hash=4a84cbc5b1eacf1afb4217e8e43c5cb50ed8d827)

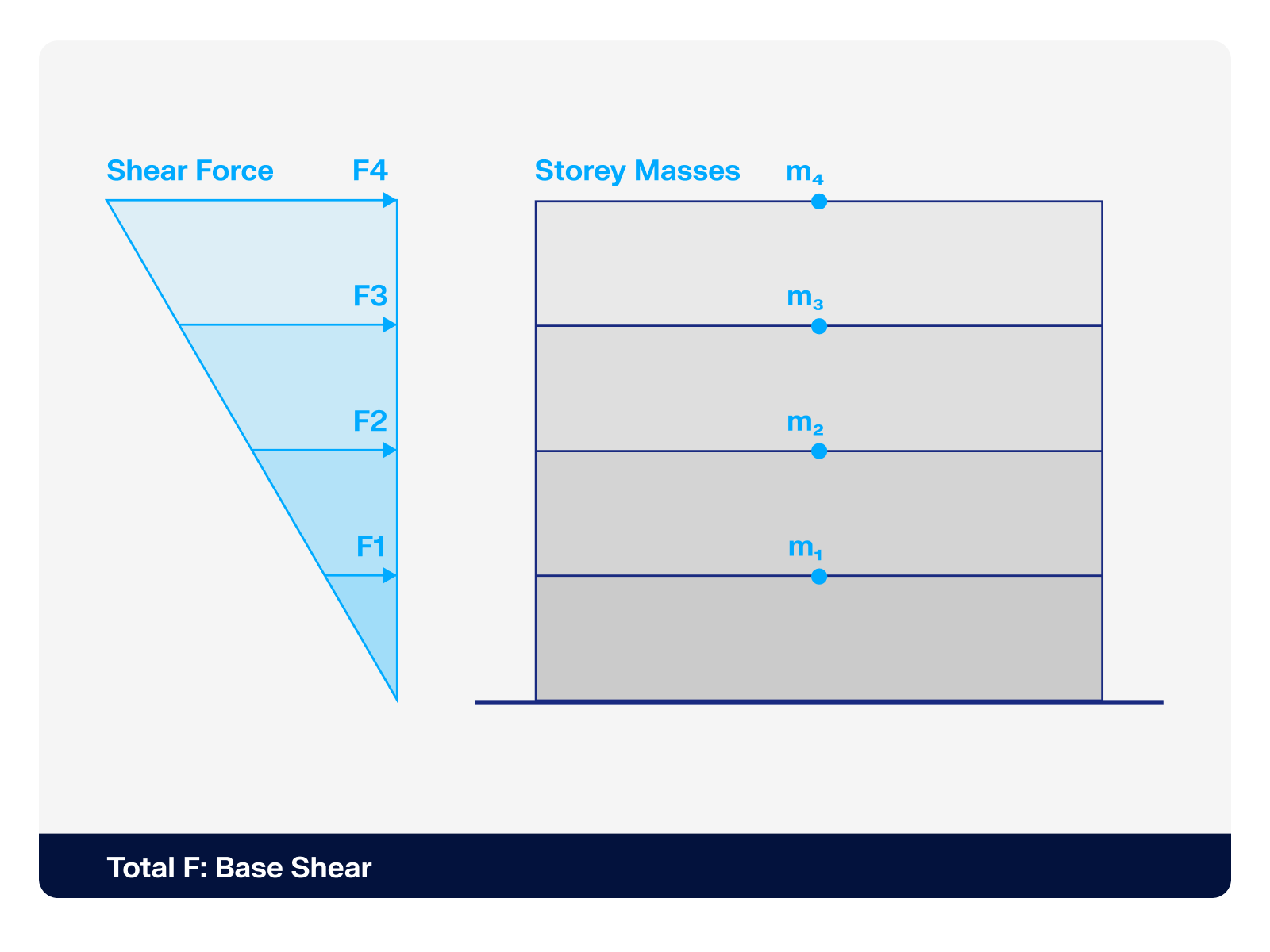

This article provides a comprehensive overview of essential seismic analysis methods, explaining their principles and applications, as well as the scenarios in which they are most effective

- General stress analysis

- Automatic import of internal forces from RFEM/RSTAB

- Complete graphical and numerical results of stresses and stress ratios integrated in RFEM/RSTAB

- Wide range of customization options for graphical output

- Flexible design in multiple design cases

- Clearly arranged result tables for a quick overview after the design

- High productivity due to the minimal amount of input data required

- Flexibility due to detailed setting options for basis and extent of calculations

- Cross-section optimization

- Transfer of optimized sections to RFEM/RSTAB

- Design of any thin-walled cross-section from SHAPE-THIN

- Representation of a stress diagram on a section

- Determination of normal, shear, and equivalent stresses

- Stress results of individual internal forces types

- Detailed representation of stresses in all stress points

- Determination of the largest Δσ for each stress point (for example, for fatigue design)

- Colored display of stresses and design ratios for a quick overview of the critical or oversized zones

- Parts lists and quantity surveying

- Determination of principal and basic stresses, membrane and shear stresses, as well as equivalent stresses and equivalent membrane stresses

- Stress analysis for structural surfaces including simple or complex shapes

- Equivalent stresses calculated according to different approaches:

- Shape modification hypothesis (von Mises)

- Shear stress hypothesis (Tresca)

- Normal stress hypothesis (Rankine)

- Principal strain hypothesis (Bach)

- Optional optimization of surface thicknesses and data transfer to RFEM

- Serviceability limit state design by checking surface displacements

- Detailed results of individual stress components and ratios in tables and graphics

- Filter function for surfaces, lines, and nodes in tables

- Transversal shear stresses according to Mindlin, Kirchhoff, or user-defined specifications

- Parts list of designed surfaces

In order to facilitate the data input, surfaces, members, sets of members, materials, surface thicknesses, and cross-sections are preset. It is possible to select the elements graphically using the [Select] function. The program provides access to the global material and cross-section libraries.

Load cases, load combinations, and result combinations can be combined in various design cases.

The combination of surface and member elements and separate designs allows you to model and analyze only critical parts, such as frame joints, using surface elements. The other parts of the model can be designed using member analyses.

The design ratio of the cross-section check is different for the RF‑/STEEL and RF‑/STEEL EC3 add-on modules. What can be the cause?

For a buckling analysis, PLATE‑BUCKLING determines the governing shear stress of τ = 7.45 kN/cm², while RF‑/STEEL gives the result of the maximum shear stress of τ = 8.20 kN/cm². Where does this difference come from?

How can I design any SHAPE‑THIN cross-section in detail in RFEM 5 or RSTAB 8?

How can I display the stresses in the stress points in RF‑STEEL Members?

What is the difference between the RF‑/STEEL and RF‑/STEEL EC3 add-on modules?

I am comparing the flexural buckling design according to the equivalent member method and the internal forces according to the linear static analysis with the stress calculation according to the second-order analysis, including imperfections. The differences are very large. What can be the reason for this?

Recommended Products for You

Dlubal_KohlA_]_LI.jpg?mw=350&hash=21d94ec9a723c608496e9e95a21bb1309ab5067a)

_3.jpg?mw=350&hash=6831ba094e54512b3726fc611ff1b3a3f24436b7)

_1.jpg?mw=350&hash=ab2086621f4e50c8c8fb8f3c211a22bc246e0552)

.png?mw=600&hash=49b6a289915d28aa461360f7308b092631b1446e)