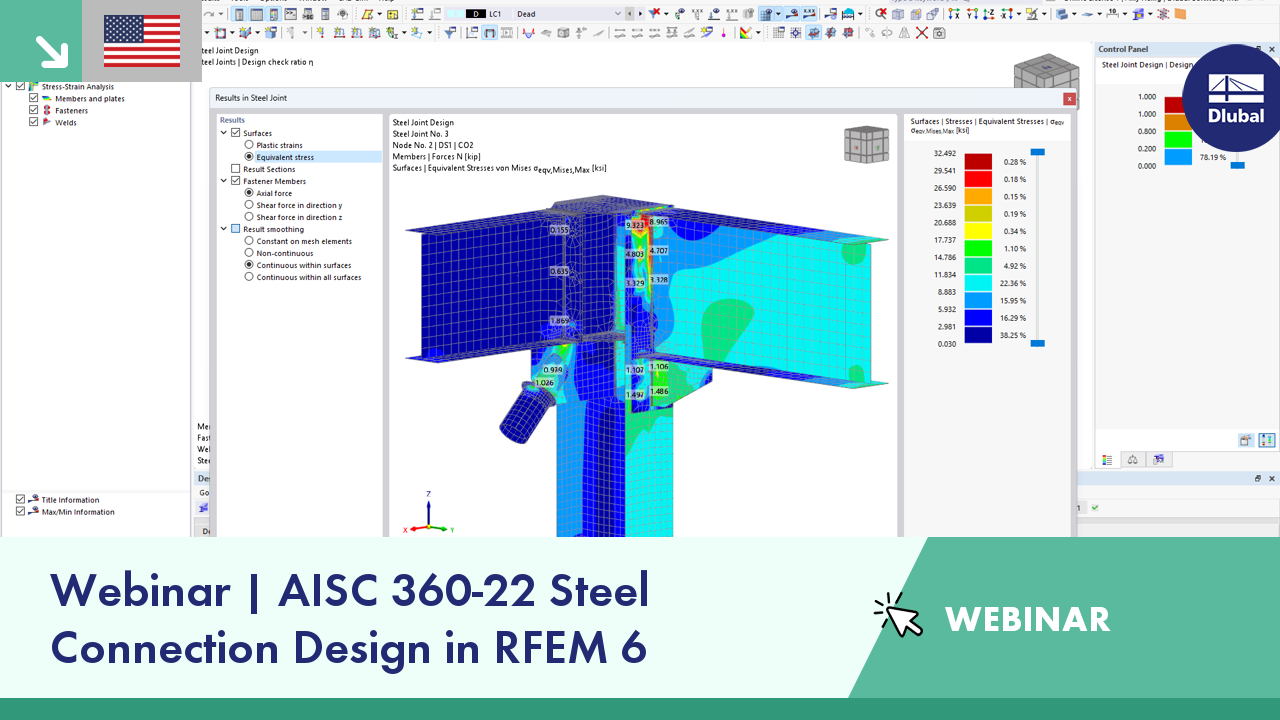

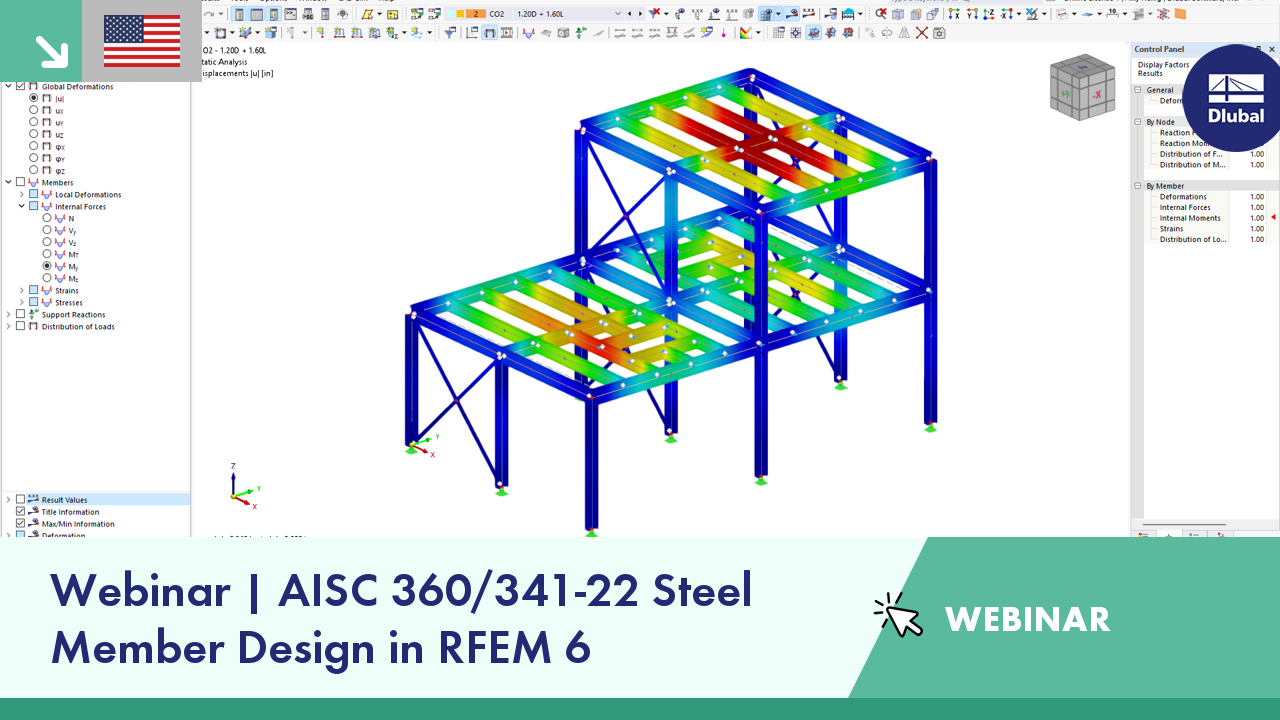

In this tutorial, we would like to inform you about the essential features of the RFEM program. In the first part, a model was defined and a structural analysis was carried out. After performing the concrete design in the second part, the third part now deals with the design of steel members. AISC 360-22 is used as a standard.

RFEM 6 | Tutorial - Steel Design (USA)

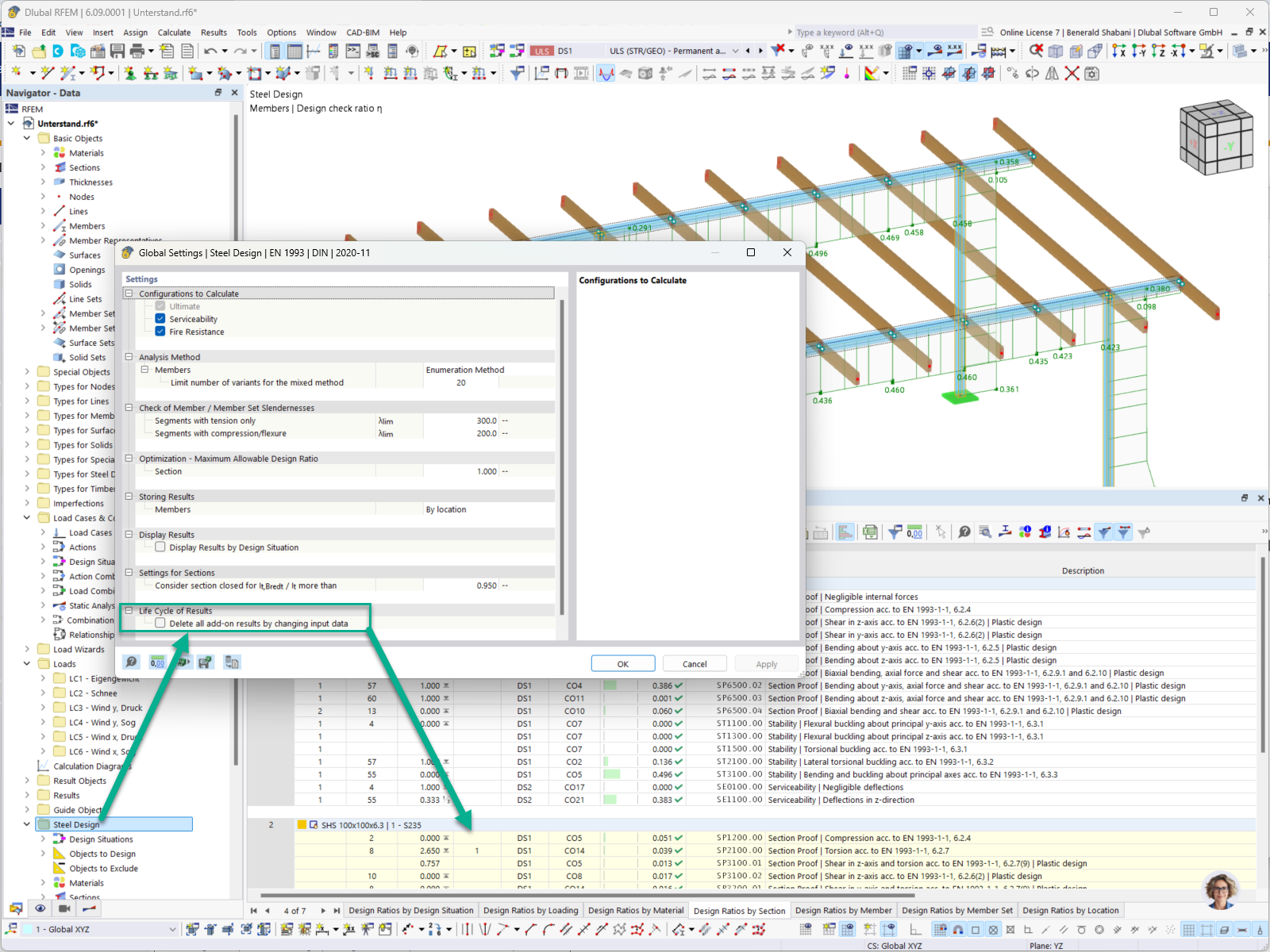

It is now possible to keep the results of the steel, steel joint, aluminum, and timber design despite changing the design properties and settings (see the setting in the image). The results are thus not deleted, but marked as invalid.

When restarting the design, only the invalid design results are updated. If objects are subsequently added to the design, they are additionally designed when restarting the design, while the previously calculated results remain valid.

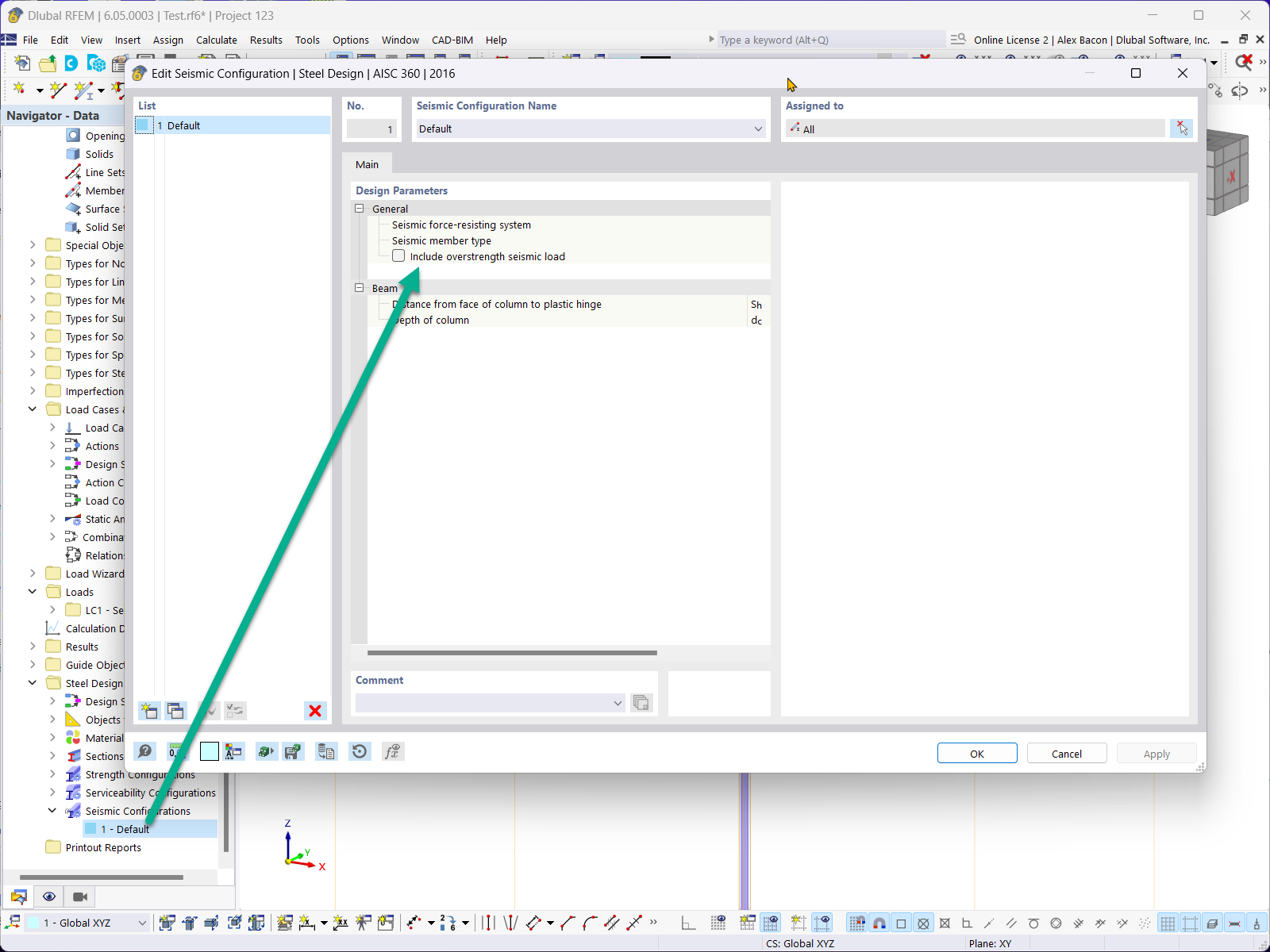

The seismic design result is categorized into two sections: member requirements and connection requirements.

The "Seismic Requirements" include the Required Flexural Strength and the Required Shear Strength of the beam-to-column connection for moment frames. They are listed in the ‘Moment Frame Connection by Member’ tab. For braced frames, the Required Connection Tensile Strength and the Required Connection Compressive Strength of the brace are listed in the ‘Brace Connection by Member’ tab.

The program provides the performed design checks in tables. The design check details clearly display the formulas and references to the standard.

In the Steel Design add-on, you can perform the seismic design of steel members according to AISC 341‑16.

Five SFRS types (Seismic Force-Resisting Systems) are available for this.

In the Steel Design add-on, you can perform the stability and cross-section design checks of cold-formed sections according to EN 1993‑1‑3 in compliance with Sections 6.1.2 – 6.1.5 and 6.1.8 – 6.1.10.

Go to Explanatory Video

.png?mw=350&hash=e70d8df86e6471bb10defcbc6d5854915810a94c)