Properties and Stresses of Thin‑Walled and Cold‑Formed Sections

SHAPE-THIN | Features

- Modeling of the cross-section via elements, sections, arcs, and point elements

- Expansible library of material properties, yield strengths, and limit stresses

- Section properties of open, closed, or non-connected cross-sections

- Ideal section properties of cross-sections consisting of different materials

- Determination of weld stresses in fillet welds

- Stress analysis including design of primary and secondary torsion

- Check of c/t-ratios

- Effective cross-sections according to

- EN 1993-1-5 (including stiffened buckling panels according to Section 4.5)

-

EN 1993-1-3

-

EN 1999-1-1

-

to DIN 18800-2

- Classification according to

-

EN 1993-1-1

-

EN 1999-1-1

-

- Interface with MS Excel to import and export tables

- Printout report

SHAPE-THIN | Cross-Section Properties and Stresses

SHAPE-THIN determines the section properties and stresses of any open, closed, built-up, or non-connected cross-sections.

- Section Properties

- Cross-sectional area A

- Shear areas Ay, Az, Au, and Av

- Centroid position yS, zS

- moments of area 2 degrees Iy, Iz, Iyz, Iu, Iv, Ip, Ip,M

- Radii of gyration iy, iz, iyz, iu, iv, ip, ip,M

- Inclination of principal axes α

- Cross-section weight G

- Cross-section perimeter U

- torsional constants of area degrees IT, IT,St.Venant, IT,Bredt, IT,s

- Location of the shear center yM, zM

- Warping constants Iω,S, Iω,M or Iω,D for lateral restraint

- Max/min section moduli Sy, Sz, Su, Sv, Sω,M with locations

- Section ranges ru, rv, rM,u, rM,v

- Reduction factor λM

- Plastic Cross-Section Properties

- Axial force Npl,d

- Shear forces Vpl,y,d, Vpl,z,d, Vpl,u,d, Vpl,v,d

- Bending moments Mpl,y,d, Mpl,z,d, Mpl,u,d, Mpl,v,d

- Section moduli Zy, Zz, Zu, Zv

- Shear areas Apl,y, Apl,z, Apl,u, Apl,v

- Position of area bisecting axes fu, fv,

- Display of the inertia ellipse

- First moments of area Qu, Qv, Qy, Qz with location of maxima and specification of shear flow

- Warping coordinates ωM

- moments of area (warping areas) Sω,M

- Cell areas Am of closed cross-sections

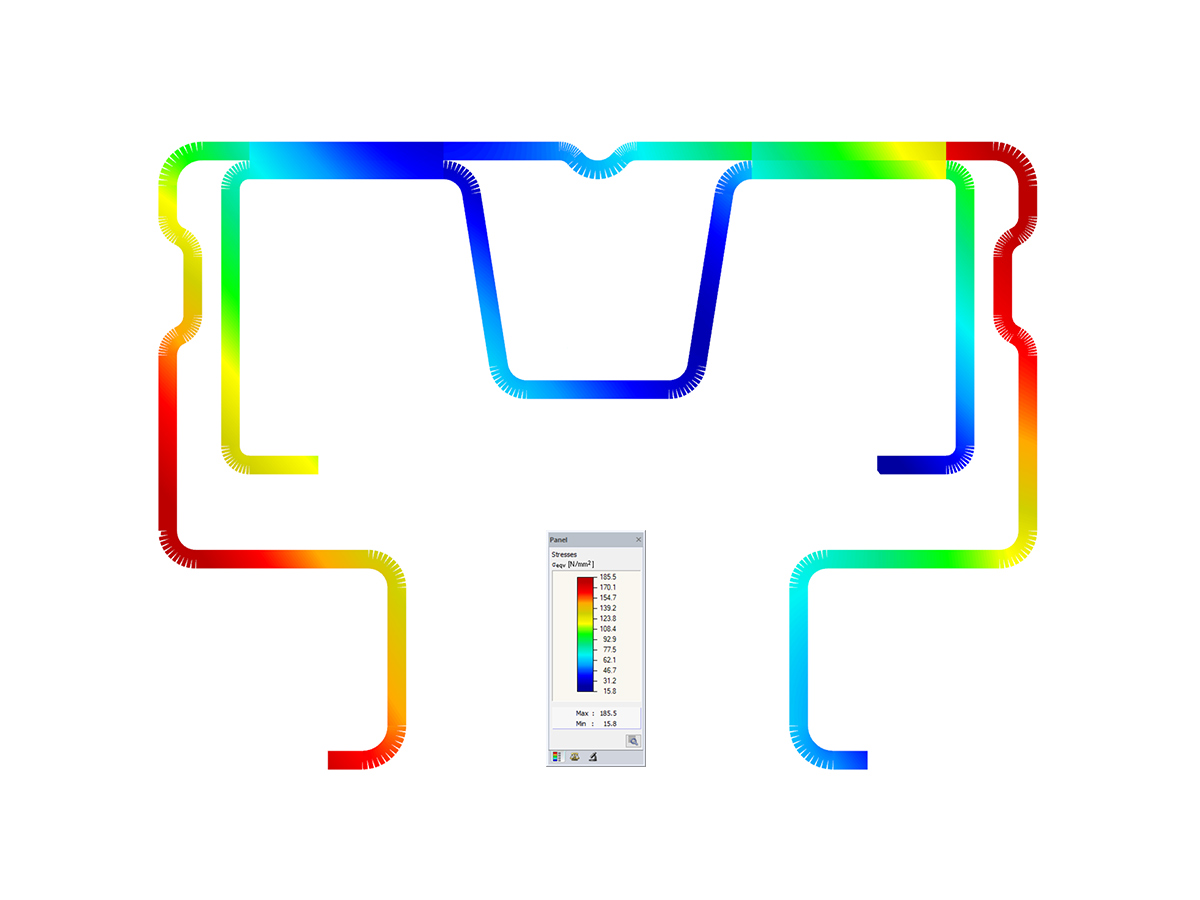

- Normal stresses σx due to axial force, bending moments, and warping bimoment

- Shear stresses τ from shear forces as well as primary and secondary torsional moments

- Equivalent stresses σv with customizable factor for shear stresses

- Stress ratios, related to limit stresses

- Stresses for element edges or center lines

- Weld stresses in fillet welds

- Section properties of non-connected cross-sections (cores of high-rise buildings, composite sections)

- Shear wall shear forces due to bending and torsion

- Plastic capacity design with determination of the enlargement factor αpl

- Check of the c/t-ratios following the design methods el-el, el-pl or pl-pl according to DIN 18800

SHAPE-THIN | Input

SHAPE-THIN includes an extensive library of rolled and parameterized cross-sections. They can be composed or supplemented by new elements. It is possible to model a section consisting of different materials.

Graphical tools and functions allow for modeling complex section shapes in the usual way common for CAD programs. The graphical entry provides the option of setting point elements, fillet welds, arcs, parameterized rectangular and circular sections, ellipses, elliptical arcs, parabolas, hyperbolas, spline, and NURBS. Alternatively, it is possible to import a DXF file that is used as the basis for further modeling. You can also use guidelines for modeling.

Furthermore, parameterized input allows you to enter model and load data in a specific way so they depend on certain variables.

Elements can be divided or attached to other objects graphically. SHAPE-THIN automatically divides the elements and provides for an uninterrupted shear flow by introducing dummy elements. In the case of dummy elements, you can define a specific thickness to control the shear transfer.

SHAPE-THIN | Input

SHAPE-THIN includes an extensive library of rolled and parameterized cross-sections. They can be composed or supplemented by new elements. It is possible to model a section consisting of different materials.

Graphical tools and functions allow for modeling complex section shapes in the usual way common for CAD programs. The graphical entry provides the option of setting point elements, fillet welds, arcs, parameterized rectangular and circular sections, ellipses, elliptical arcs, parabolas, hyperbolas, spline, and NURBS. Alternatively, it is possible to import a DXF file that is used as the basis for further modeling. You can also use guidelines for modeling.

Furthermore, parameterized input allows you to enter model and load data in a specific way so they depend on certain variables.

Elements can be divided or attached to other objects graphically. SHAPE-THIN automatically divides the elements and provides for an uninterrupted shear flow by introducing dummy elements. In the case of dummy elements, you can define a specific thickness to control the shear transfer.

SHAPE-THIN | Calculation

SHAPE-THIN calculates all relevant cross‑section properties, including plastic limit internal forces. Overlapping areas are set close to reality. If cross-sections consist of different materials, SHAPE‑THIN determines the effective cross‑section properties with respect to the reference material.

In addition to the elastic stress analysis, you can perform the plastic design including interaction of internal forces for any cross‑section shape. The plastic interaction design is carried out according to the Simplex Method. You can select the yield hypothesis according to Tresca or von Mises.

SHAPE-THIN performs a cross-section classification according to EN 1993-1-1 and EN 1999-1-1. For steel cross-sections of cross-section class 4, the program determines effective widths for unstiffened or stiffened buckling panels according to EN 1993-1-1 and EN 1993-1-5. For aluminum cross-sections of cross-section class 4, the program calculates effective thicknesses according to EN 1999-1-1.

Optionally, SHAPE‑THIN checks the limit c/t-values in compliance with the design methods el‑el, el‑pl, or pl‑pl according to DIN 18800. The c/t-zones of elements connected in the same direction are recognized automatically.

SHAPE-THIN | Results

All results can be evaluated and visualized in an appealing numerical and graphical form. Selection functions facilitate the targeted evaluation.

The printout report corresponds to the high standards of RFEM 6 and RSTAB 9. Modifications are updated automatically.

Calculate Your Price

The price is valid for United States.

.png?mw=192&hash=f63e4a3f1836233005de32f60201d5392e507cf1)