Pinned Joints According to EN 1993-1-8

RF-/JOINTS Steel - Pinned | Features

General

- Beam to Column joint category: connection possible on the column flange as well as on the column web

- Beam to Beam joint category: optional arrangement of ribs on the opposite side

- Bolt sizes from M12 to M36 with the strength grades 4.6, 5.6, 8.8, and 10.9

- Arbitrary bolt hole spacing and edge distances

- Notching of the beam is possible

- Connection with pure shear loading, pure normal force load (tension joint), or possible combination of normal and shear forces

- Checking compliance with the requirements for pinned joints

- Check of the minimum and maximum bolt hole spacing and edge distances

Web cleat connections

- One or two vertical and up to 10 horizontal bolt rows possible at each leg

- Wide range of equal and unequal angles

- Possible to modify angle orientation

- Designs:

- Shear, bearing resistance, and tension design of bolts

- Shear, bending, and tension design of angles considering deduction of bolt hole

- Shear and tension design of girder web considering deduction of bolt hole

- Tension transmission into the column with the T-stub model

- Notching at the critical section

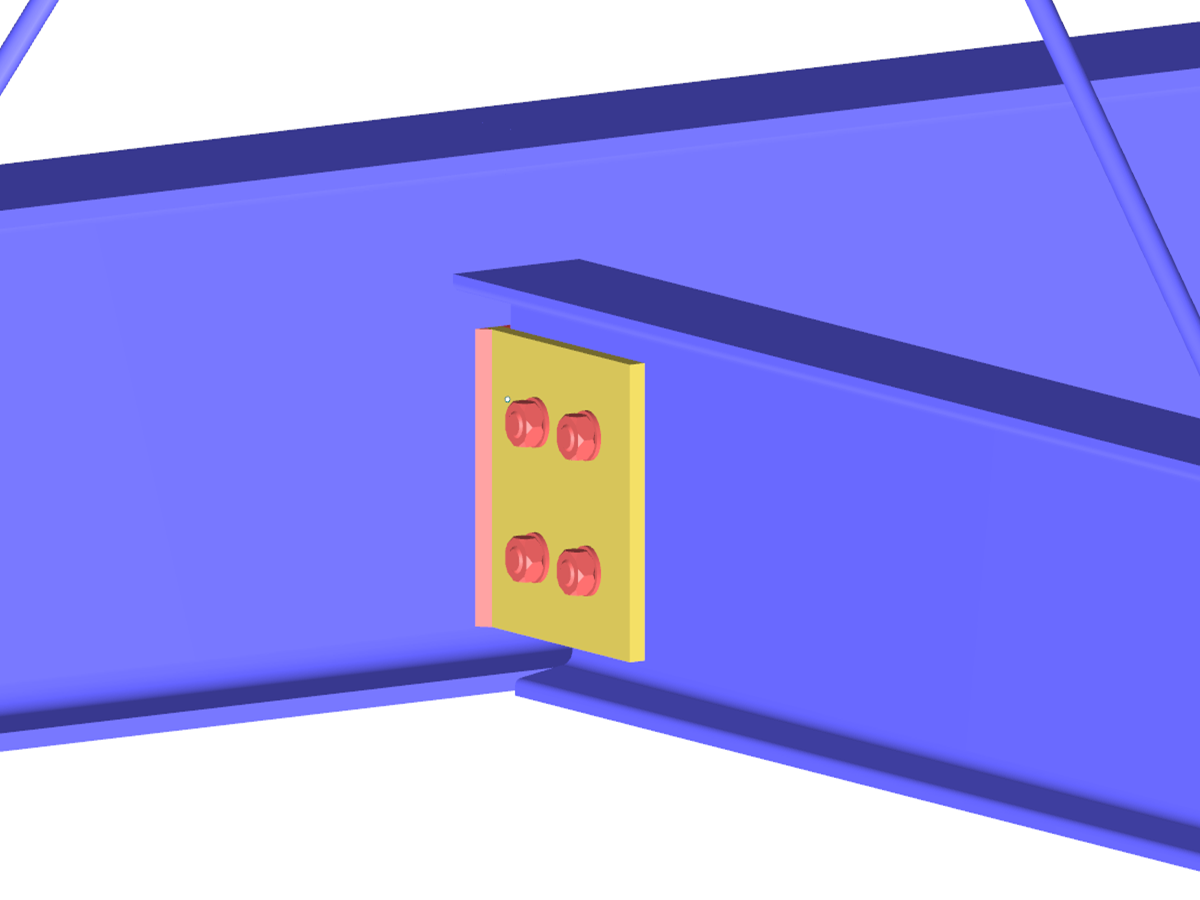

Fin plate connection

- One or two vertical and up to 10 horizontal bolt rows are possible

- Flexible size of the fin plate

- Location of the fin plate can be modified

- Designs:

- Shear and bearing resistance design of bolts

- Shear, bending, and tension design of fin plates considering deduction of bolt hole

- Stability analysis of long, slender fin plates

- Shear and tension design of girder web considering deduction of bolt hole

- Weld as fillet weld

- Notching at the critical section

End plate connection

- Two or four vertical and up to 10 horizontal bolt rows

- Flexible size of the end plate

- Location of the fin plate can be modified

- Designs:

- Shear, bearing resistance, and tension design of bolts

- Shear and bending design of end plates considering deduction of bolt hole

- Shear and tension design of girder web

- Tension transmission into the column with the T-stub model

- Weld as fillet weld

- Notching at the critical section

End plate connection with cleat

- Fixation of the beam by end plate with two bolts

- Flexible size of cleat and end plate

- Designs:

- Load introduction into the beam according to EN 1993-1-5, Chapter 6

- Support of the stabilizing moment by the bolts and welds at the end plate

- Cleat

- Cleat welds as fillet welds

- Tension transmission into the column with the T-stub model

RF-/JOINTS Steel - Pinned | Input

After opening the add-on module, it is necessary to select the joint group (Pinned Joints), then the joint category and joint type (web cleat, fin plate, short end plate, end plate with cleat). Then, you can select the nodes for design in the RFEM/RSTAB model. RF-/JOINTS Steel - Pinned automatically recognizes the joint members and determines from its location whether they are columns or beams.

It is possible to exclude particular members from the calculation, if required. Structurally similar connections can be designed for several nodes at the same time. Loads require selection of the governing load cases, load combinations, or result combinations. Alternatively, you can enter the cross‑section and load data manually. In the last input window, the connection is configured step by step.

RF-/JOINTS Steel - Pinned | Structural Analysis

All joint types are considered with the moment release at the column flange, or at the column web in the case of a rotated column. Therefore, the module determines the eccentric moment of a web cleat and fin plate connection, which additionally affects the bolt group at the girder flange.

Further eccentric moments may result from the locations of the angles and sheets. In the case of cleat connection, the forces are transferred separately. Shear forces act on the cleat; tension forces and stabilizing moment are assigned to the bolts. Before the calculation, the connection is checked for geometrical plausibility; for example, the bolt hole spacing and edge distance of the bolts.

RF-/JOINTS Steel - Pinned | Results

The result windows list all results of the calculation in detail. In addition, 3D graphics are created, where individual components as well as dimension lines and, for example, This allows you, for example, to display or hide the weld data. The summary shows if the individual designs have been fulfilled: The design ratio is additionally visualized with a green data bar, which turns red when the design is not fulfilled. Furthermore, the node number and the governing LC/CO/RC are displayed.

When selecting a design, the module shows the detailed intermediate results including the actions and the additional internal forces from the connection geometry. There is the option to display the results by load case and by node. The connections are represented in a realistic 3D rendering possible to scale. In addition to the main views, it is possible to show the graphics from any perspective.

You can add the graphics with dimensions and labels to the RFEM/RSTAB printout or export them as DXF. The printout report includes all input and result data prepared for test engineers. It is possible to export all tables to MS Excel or in a CSV file. A special transfer menu defines all specifications required for the export.

Webshop

Customize your individual program package and find out all the prices online!

Calculate Your Price

The price is valid for United States.

.png?mw=1024&hash=0d71358c0df4c164c1e58ae7aec0ac6978c9680d)

.png?mw=192&hash=f63e4a3f1836233005de32f60201d5392e507cf1)