I collegamenti analizzati nel componente aggiuntivo Connessioni in acciaio utilizzano un modello FE di connessione in acciaio sostitutivo ("sottomodello") per la progettazione. Questo modello viene creato sulla base della topologia del collegamento. I singoli componenti di progettazione, come lastre, saldature o bulloni, vengono rappresentati in questo modello tramite oggetti FE di base – superfici o aste –, che vengono integrati con oggetti speciali come contatti superficiali o accoppiamenti rigidi. Questo approccio consente di confrontare il comportamento dei componenti di base con le formule analitiche delle norme di progettazione. Usando questo "sottomodello" è possibile analizzare la capacità portante e la stabilità a instabilità, nonché la rigidezza e la capacità di deformazione del collegamento.

Le dimensioni del sottomodello vengono determinate proporzionalmente alla dimensione della sezione trasversale delle aste connesse. Le aste modellate con superfici 2D vengono estese assialmente di un multiplo della dimensione massima della sezione trasversale oltre i componenti del collegamento. Questo fattore è impostato di default a 1,5, ma può essere adattato nella Configurazione della capacità portante. Come riferimento per la distanza si utilizza il componente più lontano del collegamento.

Nel sottomodello, l'estremità di un'asta connessa viene installata rigidamente o caricata con un carico sostitutivo calcolato nel modello globale, a seconda delle impostazioni dell'utente. I carichi alle estremità delle aste si basano sui carichi interni del modello complessivo e si adattano in modo che il loro effetto corrisponda ai carichi interni sul componente particolare nel nodo a cui il collegamento è assegnato. Le estremità dell'asta vengono irrigidite con una superficie rigida per prevenire la distorsione della sezione trasversale ed evitare concentrazioni di tensione nel nodo caricato o sostenuto.

Di default, il modello FE di connessione in acciaio sostitutivo utilizza l'analisi geometrico-lineare in combinazione con un modello di materiale non lineare per il calcolo della capacità portante. Per analizzare le non linearità del modello, viene applicato il metodo iterativo di Newton-Raphson. L'analisi non lineare del secondo ordine (P-Δ) viene utilizzata come impostazione predefinita per l'analisi strutturale nella valutazione dell'instabilità, mentre per l'analisi di stabilità viene utilizzato il metodo degli autovalori lineari. Ulteriori informazioni si trovano nel capitolo Impostazioni per l'analisi statica del manuale RFEM.

Quando nella analisi statica del modello principale si considera la teoria del secondo o terzo ordine, ciò può portare a incoerenze tra il modello principale (l'equilibrio viene stabilito sul sistema deformato) e il sottomodello (le forze vengono esercitate sul sottomodello non deformato). Tuttavia, per i tipici sistemi strutturali, questo effetto dovrebbe essere trascurabile.

Modello del materiale

Le superfici che rappresentano le piastre dell'asta e le lastre integrate nel sottomodello hanno uno spessore uniforme e sono soggette a un modello di materiale isotropo-plastico. L'ipotesi di rottura della tensione è basata sul criterio di snervamento di von Mises. Viene utilizzato un diagramma bilineare, dopo il quale il materiale si deforma elasticamente fino al limite di snervamento sotto il modulo di elasticità dell'acciaio. Nella successiva fase plastica, il modulo plastico corrisponde a 1/1000 del modulo di elasticità.

Il criterio per determinare la resistenza limite corrisponde a una deformazione plastica equivalente di von Mises del 5%. Questo valore è raccomandato ma può essere adattato nella Configurazione della capacità portante. Questo permette di sfruttare il comportamento plastico dell'acciaio e le ridistribuzioni delle tensioni nel collegamento. Questo corrisponde al comportamento reale di un collegamento in acciaio con una buona approssimazione.

Aste e lastre

Per la modellazione di piastre dell'asta piane e piastre integrate, vengono utilizzati il tipo di geometria Piano e il tipo di rigidità Standard. Le superfici hanno uno spessore uniforme e sono dotate di un modello di materiale isotropo-plastico descritto nella sezione Modello del materiale. Le superfici sono oggetti 2D che si trovano nei piani mediani delle lastre. Se le singole lastre che rappresentano l'asta non possono essere connesse direttamente tramite le loro linee di delimitazione, si utilizza una connessione con accoppiamenti rigidi. Il tipo di accoppiamento "Linea a linea" collega la linea di delimitazione della lastra connessa con la linea integrata creata nella lastra a cui è connessa. Questa connessione viene utilizzata ad esempio per i profili a I.

Aste o parti di esse da superfici non piane, come profili cavi circolari o profili cavi rettangolari arrotondati, vengono modellate segmentando la sezione curva come superfici piane più piccole. Queste superfici hanno le stesse proprietà delle superfici utilizzate per lastre piane. Il grado di segmentazione può essere adattato dall'utente nella Configurazione della capacità portante.

Rete

Le impostazioni delle mesh per tutte le superfici consentono elementi finiti triangolari e quadrangolari con l'opzione "Genera quadrati uguali, dove possibile".

Le lastre di ciascuna asta hanno la stessa dimensione degli elementi della mesh. Le dimensioni minime e massime degli elementi sono impostate di default. La dimensione di un elemento viene derivata dalla dimensione della sezione trasversale dell'asta. Di default, il bordo più lungo della sezione viene suddiviso in otto parti. L'impostazione della mesh delle lastre integrate viene trattata separatamente: la dimensione dell'elemento della mesh viene derivata dal bordo più lungo della lastra. Per una lastra senza bulloni vengono creati di default otto elementi sul bordo più lungo, per una lastra imbullonata vengono creati di default 16 elementi.

Nell'area dei bulloni viene applicata una rete nodale circolare alle superfici delle lastre imbullonate. Per questa rete nodale circolare, è possibile impostare il raggio come multiplo del raggio del foro del bullone e definire il numero di elementi sul bordo del foro.

Per la superficie sostitutiva della saldatura a cordone, è possibile definire il numero massimo di elementi lungo la lunghezza della saldatura e le dimensioni minime e massime degli elementi.

I nodi della mesh sono collegati tramite Accoppiamenti rigidi e Contatti superficiali con linee o superfici connesse. Questo influenza la mesh della superficie connessa, quindi la sua discrezione non è completamente indipendente.

Bulloni

Il modello del bullone consiste in un sistema di aste, superfici e contatti superficiali che rappresentano le singole parti del bullone, lo stelo, la testa e il dado. Per ciascun bullone viene generato automaticamente un foro nelle lastre imbullonate.

Il foro viene riempito con aste disposte radialmente, chiamate "raggi". Queste aste del tipo "Trave" servono a trasferire la forza di taglio tra lo stelo del bullone e la lastra. Il numero di queste aste è influenzato dalle impostazioni della mesh e corrisponde al numero di elementi sul bordo del foro. La sezione trasversale di queste aste è un "rettangolo massiccio", le cui dimensioni sono influenzate dal numero delle aste e dalle dimensioni delle lastre imbullonate. Esse corrispondono all'area dello stelo del bullone nel lager.

Un giunto dell'asta viene assegnato ai nodi in cui i raggi sono collegati alla lastra. Il giunto è impostato per ciascun nodo in modo tale che le aste non rafforzino il foro nella lastra e trasferiscano solo la forza di taglio tra la lastra e il bullone.

Gli elementi dei raggi mostrano una non linearità del tipo "Guasto a trazione" in modo tale che solo la parte compressa del bullone abbia effetto. A esse viene assegnato un materiale isotropo lineare-elastico che corrisponde all'acciaio nello stato elastico.

Il modello della testa del bullone e del dado utilizza anch'esso una serie di aste radiali ("raggi"), poiché si riferisce al foro della lastra imbullonata. Tuttavia, questi raggi differiscono per le loro dimensioni della sezione trasversale, in modo che rappresentino l'altezza della testa della vite o del dado. Inoltre, non vengono assegnati giunti agli estremi delle aste né una non linearità di guasto. Questo set di raggi viene esteso da una superficie anulare collegata ai raggi radialmente disposti. Per la superficie vengono utilizzati il tipo di geometria "Piano" e il tipo di rigidità "Standard", con uno spessore uniforme che corrisponde all'altezza della testa del bullone o del dado.

I punti centrali del sistema radiale di aste, che rappresentano la testa del bullone, lo stelo del bullone nel foro e il dado del bullone, sono collegati da un'asta che rappresenta la testa del bullone e la filettatura. A essa viene assegnato il tipo di asta "Trave", ed è denominato "Shaft". Lo shaft ha una sezione trasversale circolare, la cui area corrisponde alla sezione resistente del bullone. Il materiale della sezione trasversale è isotropo lineare elastico.

Il tipo di asta "Rigidità" viene utilizzato nella sezione tra le lastre imbullonate. La matrice di rigidità corrisponde all'asta utilizzata tra la testa del bullone (o il dado) e la lastra imbullonata; la sola differenza risiede nella rigidità alla flessione, che è notevolmente aumentata. Se la rigidezza non fosse regolata, si verificherebbe una flessione fisicamente irrealistica del bullone nella posizione in cui le forze sono effettivamente trasferite esclusivamente attraverso la frizione. Il comportamento plastico di questa parte dello shaft del bullone è rappresentato da un giunto dell'asta di tipo "Diagramma" alla connessione delle lastre imbullonate.

Le forze di compressione che si generano nel contatto delle lastre imbullonate e tra queste lastre e la testa del bullone o il dado, vengono trasferite tramite Contatti superficiali. Vengono stabiliti tra la superficie dell'anello della testa del bullone e la superficie che rappresenta la prima lastra imbullonata, tra le singole lastre imbullonate che si toccano e tra la superficie che rappresenta l'ultima lastra imbullonata e l'anello del dado. Il tipo di contatto superficiale viene impostato in direzione perpendicolare alle superfici su "Guasto a trazione" e al contatto parallelo alle superfici su "Attrito rigido". Qui il coefficiente di attrito viene impostato su un valore vicino a zero. Questi contatti consentono di generare la giusta forza assiale sullo shaft del bullone. La forza di trazione di progetto e la forza di taglio di progetto come risultato delle forze di taglio interne in direzione y e z, utilizzate per le verifiche di progetto, si generano sullo shaft tra le lastre imbullonate.

I numeri nella figura sopra indicano i seguenti componenti:

| 1 | Shaft del bullone – asta di tipo "Rigidità" |

| 2 | Foro del bullone – raggi |

| 3 | Dado – anello superficiale |

| 4 | Dado – raggi |

| 5 | Stelo del bullone |

| 6 | Dado – contatto superficiale |

| 7 | Testa del bullone – contatto superficiale |

| 8 |

|

| 9 | Testa del bullone – anello superficiale |

Bulloni pre-tesi

Il pretensionamento del bullone viene applicato nel contesto di un proprio caso di carico nel sottomodello. Questo caso di carico Pretensionamento del bullone viene poi considerato come stato iniziale per il caso di carico di progetto effettivo. In base al fattore di pre-tensionamento, che è indicato nella Configurazione della capacità portante (e che di default è pari a 0,7 secondo EN 1993-1-8), il pretensionamento viene applicato come carico dell'asta sullo shaft del bullone in funzione del carico assiale.

Saldature

Il modello delle saldature di testa completamente penetrate utilizza una connessione diretta tra le lastre saldate. Viene implementato tramite accoppiamenti rigidi di tipo "Linea a linea". La connessione è simile alla connessione tra le parti della sezione trasversale di un'asta (piastre dell'asta). Questo tipo di accoppiamento rigido utilizza le opzioni "Distribuzione personalizzata" e "Ignora influenza della distanza".

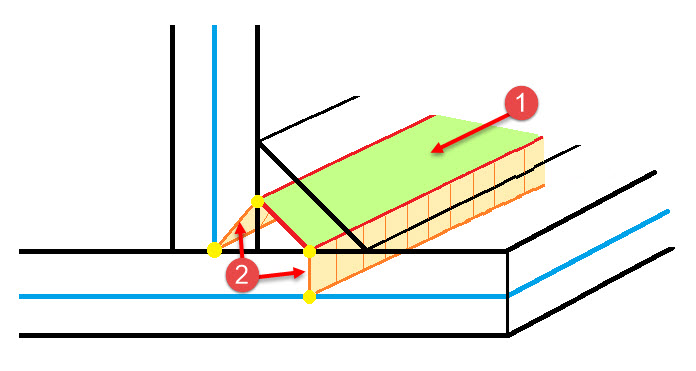

Il modello delle saldature a cordone utilizza anch'esso un sistema di accoppiamenti rigidi (vedi ➁ nella figura seguente) e superfici sostitutive (vedi ➀ nella figura seguente) per la connessione della saldatura.

Il tipo di accoppiamento rigido è "Linea a linea" con le opzioni "Distribuzione personalizzata" e "Ignora influenza della distanza", dove il bordo della lastra saldata viene collegato con il bordo della superficie della saldatura sostitutiva e il secondo bordo di questo con la lastra di riferimento. La superficie sostitutiva si trova a metà altezza della sezione trasversale triangolare della saldatura a cordone. Questa altezza viene chiamata "spessore del colletto" della saldatura a cordone. La superficie sostitutiva della saldatura a cordone ha il tipo di rigidità "Standard" e uno spessore uniforme con dimensioni corrispondenti allo spessore del colletto della saldatura. Viene applicato un modello di materiale ortotrotropo-plastico appositamente adattato ai criteri di rottura.

Il Modello di materiale della saldatura è impostato per corrispondere al comportamento della saldatura considerato nelle norme. Ciò significa che sulla superficie sostitutiva si verificano solo tensioni che corrispondono ai componenti di tensione della saldatura σ⊥, τ⊥ e τ||. Nelle restanti direzioni di tensione, la rigidità della superficie sostitutiva è quasi nulla.

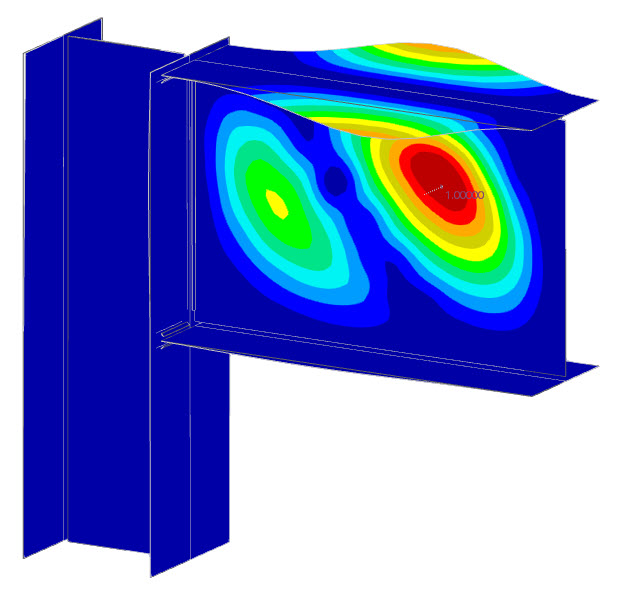

Analisi di stabilità

L'approccio del "modello FE di connessione in acciaio sostitutivo" è adatto anche per la valutazione delle instabilità delle piastre in acciaio utilizzando un'analisi FE del modello a guscio. A tal fine, il modello utilizzato per l'analisi statica viene adattato in un certo modo, in modo da utilizzare infine il "modello FE della stabilità del collegamento in acciaio sostitutivo" ("sottomodello di stabilità").

Le impostazioni modificate del "sottomodello di stabilità" sono le seguenti:

- Tutti i materiali utilizzati vengono considerati elastici (materiale di aste e lastre, tutte le parti del modello del bullone, superficie sostitutiva della saldatura).

Il modello è caricato alle estremità tramite deformazioni imposte dei nodi anziché dalle forze dal modello strutturale globale. Queste deformazioni corrispondono ai carichi dei nodi, ma il loro utilizzo garantisce che le aste libere non influenzino negativamente i risultati dell'analisi di stabilità.

- Di default, il sottomodello di stabilità utilizza il tipo di analisi "Secondo ordine (P-Δ)" per l'analisi statica e il "Metodo degli autovalori (lineare)" con i quattro autovalori più bassi per l'analisi della stabilità.

Dopo il calcolo, il modello fornisce il numero richiesto di autovalori con il rispettivo fattore di carico critico. Spetta all'utente valutare se la stabilità del collegamento in acciaio sia sufficiente.

Analisi della rigidità

Per determinare la rigidità del collegamento vengono utilizzati due sottomodelli. Si tratta del modello principale FE di rigidità sostitutivo (Sottomodello di rigidità) – un modello a guscio dettagliato che, eccetto per i carichi e i supporti, è identico al sottomodello utilizzato per l'analisi statica – e il Modello FE di rigidità ausiliario (Sottomodello ausiliario di rigidità), utilizzato per considerare gli effetti delle deformazioni delle aste connesse.

I parametri di progettazione del "sottomodello di rigidità" vengono gestiti nella Configurazione dell'analisi della rigidità. Con questa impostazione, è possibile selezionare il "Tipo di analisi" (geometrico lineare o P-Δ di secondo ordine) e definire il "Numero massimo di iterazioni" e il "Numero di passi di carico". Inoltre, è possibile controllare la dimensione del modello e le impostazioni della mesh, in modo simile alle impostazioni della configurazione della capacità portante che si applicano all'analisi tensione-deformazione del collegamento. Anche ulteriori parametri del modello vengono ereditati dalla configurazione della capacità portante.

Le componenti di carico applicate a entrambi i sottomodelli (Sottomodello di rigidità e Sottomodello ausiliario di rigidità) corrispondono alle rigidità del giunto da analizzare. La rigidità viene analizzata per ciascun'asta nel giunto separatamente. L'asta analizzata viene caricata all'estremità con un carico di piccola entità, che corrisponde al tipo e alla direzione della rigidità analizzata S (SN+, SN-, SMy+, SMy-, SMz+, SMz-). Le altre aste nel collegamento vengono sostenute rigidamente alle loro estremità. La dimensione del carico per determinare la "rigidità iniziale" dipende dalle dimensioni di ciascuna asta connessa.

Dopo aver eseguito il calcolo, viene utilizzato il sottomodello di rigidità per determinare la deformazione (rotazione o spostamento) all'estremità di ciascuna asta analizzata. La deformazione ottenuta dal sottomodello ausiliario di rigidità viene sottratta da questa deformazione per considerare la rigidità delle aste connesse. Il risultato è la rigidità del collegamento calcolata dalla forza e dalla deformazione. In base a questa rigidità, le connessioni possono essere classificate come "cerniere", "cedevoli" o "rigide a flessione".