W przeszłości podczas modelowania połączeń inżynierowie często ograniczali się do dwóch opcji: sztywne lub przegubowe. Te uproszczone założenia rzadko odzwierciedlają rzeczywiste zachowanie połączeń stalowych, które wykazują częściową elastyczność. Wraz z wprowadzeniem przegubów półsztywnych, program RFEM 6 oferuje teraz trzecią, bardziej zróżnicowaną opcję. Dzięki symulacji rzeczywistej sztywności połączeń, ta nowa funkcja umożliwia dokładniejszą analizę rozkładu sił i naprężeń w konstrukcji, co prowadzi do bardziej precyzyjnych i wiarygodnych wyników obliczeń.

Jak to działa: Przeguby półsztywne w RFEM 6

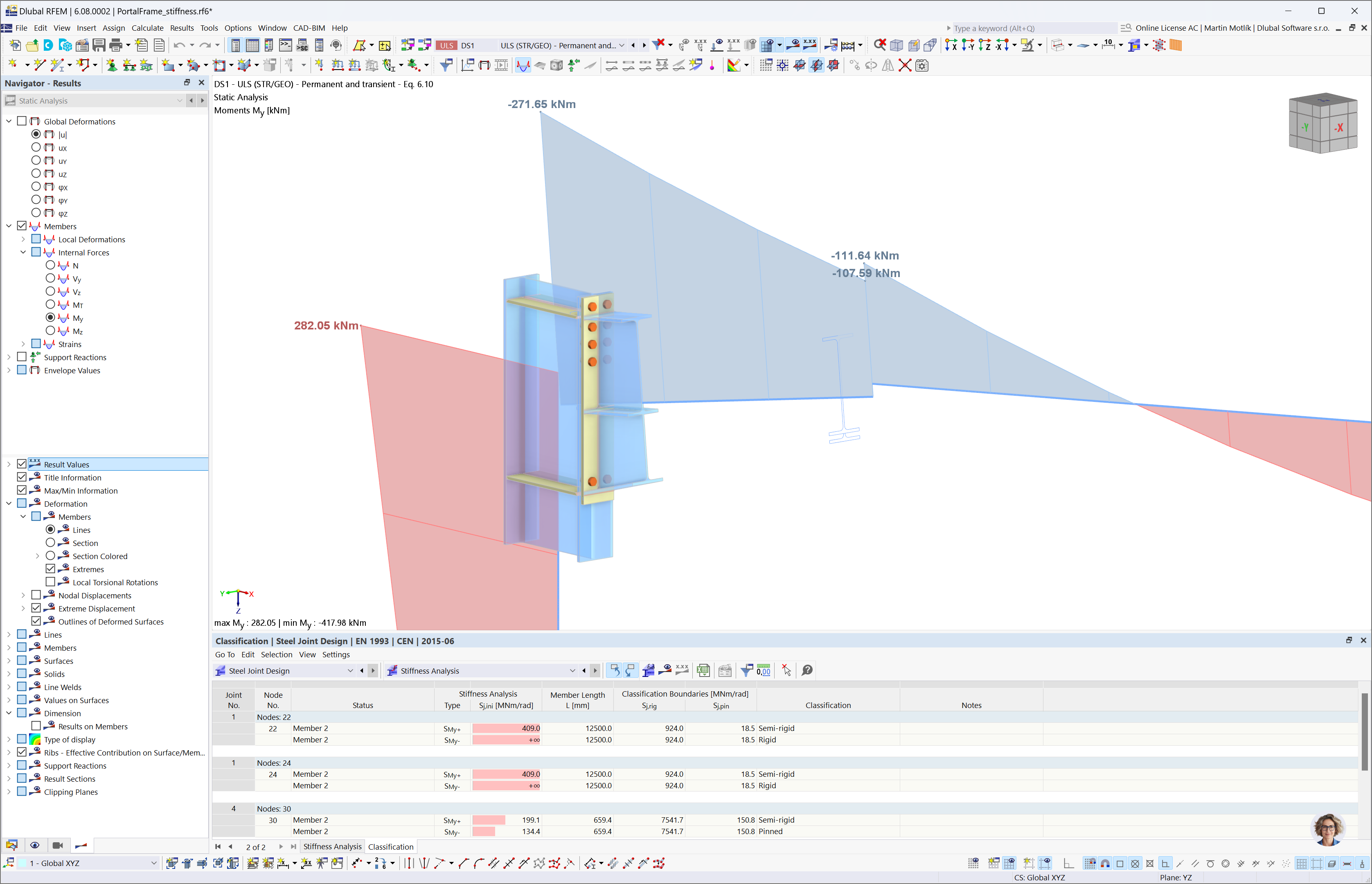

Funkcja przegubów podatnych opiera się na integracji przegubów z modelem globalnym przed obliczeniami sił wewnętrznych, w oparciu o początkową analizę sztywności. Proces rozpoczyna się od automatycznego wygenerowania przez rozszerzenie Połączenia stalowe, tych półsztywnych połączeń, odzwierciedlających rzeczywistą sztywność połączeń. Funkcja ta eliminuje potrzebę ręcznego, czasochłonnego wprowadzania sztywności i zamiast tego pozwala użytkownikom skoncentrować się na ogólnym projektowaniu konstrukcji, wiedząc, że zachowanie połączenia jest dokładnie uchwycone.

Symulacja przegubów półsztywnych wykracza daleko poza tradycyjne podejścia do modelowania połączeń. Dzięki dokładnemu uwzględnieniu częściowej sztywności połączeń stalowych funkcja ta zapewnia inżynierom bardziej realistyczny wgląd w to, jak ich konstrukcje będą zachowywać się pod wpływem różnych obciążeń. Skutkuje to bardziej wydajnym i precyzyjnym projektowaniem, umożliwiając inżynierom przewidywanie potencjalnych problemów i optymalizację wykorzystania materiałów.

Dlaczego przeguby półsztywne w Twoich projektach

Włączenie przegubów półsztywnych do programu RFEM 6 ma kilka kluczowych zalet w projektach konstrukcyjnych. Przede wszystkim zapewnia dokładniejsze modelowanie połączeń stalowych. W wielu projektach zachowanie połączeń odgrywa kluczową rolę w przenoszeniu obciążeń i reakcji konstrukcji pod wpływem naprężeń. Poprzez uwzględnienie częściowej podatności w modelach połączeń inżynierowie mogą lepiej zrozumieć rozkład sił w konstrukcji, zapewniając, że wszystkie elementy są zaprojektowane tak, aby przenosić rzeczywiste obciążenia, z jakimi będą się stykać.

Ten poziom dokładności jest szczególnie istotny w przypadku złożonych projektów lub projektów o dużej skali, w których zachowanie połączeń może bezpośrednio wpływać na bezpieczeństwo i działanie konstrukcji. W wielu uproszczonych obliczeniach często zakłada się, że połączenia są w pełni przegubowe, pomijając podatny charakter rzeczywistych połączeń. Przeoczenie może prowadzić do nieoczekiwanych sił związanych z momentem, które, jeśli nie zostaną odpowiednio uwzględnione, mogą skutkować problemami konstrukcyjnymi, a nawet uszkodzeniem. Dzięki zastosowaniu przegubów półsztywnych inżynierowie mogą dokładnie symulować te momenty, co znacznie poprawia bezpieczeństwo poprzez zapobieganie niebezpiecznemu niedoszacowaniu zachowania połączenia. To zaawansowane modelowanie ogranicza potrzebę stosowania zbyt konserwatywnych projektów i niepotrzebnego wykorzystania materiałów, dzięki czemu inżynierowie mogą podejmować bardziej świadome decyzje i tworzyć opłacalne rozwiązania bez utraty bezpieczeństwa.

Kolejną kluczową zaletą przegubów podatnych w programie RFEM 6 jest możliwość obliczenia początkowej sztywności wielu połączeń w całej konstrukcji, a nie tylko w jednym połączeniu. Podczas gdy inne programy często koncentrują się na pojedynczych połączeniach lub podstawowych schematach statycznych, RFEM 6 analizuje wpływ połączeń półsztywnych, w pełni sztywnych lub przegubowych na cały model. To kompleksowe podejście pozwala na lepszą optymalizację wykorzystania materiałów, rozkładu obciążenia i spełnianie norm bezpieczeństwa, dzięki czemu inżynierowie mogą być coraz bardziej zmuszeni do opracowywania projektów z większą dokładnością.

Duży krok naprzód w projektowaniu konstrukcji

Integracja przegubów półsztywnych z programem RFEM 6 to coś więcej niż nowa funkcja - oznacza zmianę w podejściu inżynierów do modelowania konstrukcji stalowych. Zapewniając bardziej szczegółowy i realistyczny obraz zachowania połączenia, funkcja przegubów półsztywnych pomaga inżynierom tworzyć obliczenia, które są nie tylko dokładniejsze, ale także bardziej wydajne i oszczędne.

Jest to szczególnie ważne w dzisiejszym krajobrazie inżynierskim, w którym istnieje coraz większa presja na optymalizację zasobów przy jednoczesnym zachowaniu wysokich standardów bezpieczeństwa i wydajności. Możliwość symulowania przegubów półsztywnych oznacza, że inżynierowie mogą uniknąć nadmiernej inżynierii w swoich projektach i zamiast tego skupić się na tworzeniu bardziej inteligentnych i efektywnych rozwiązań.

Innowacja, która zwiększa możliwości Twoich projektów

W Dlubal Software naszym celem jest ciągłe zwiększanie możliwości programu RFEM 6, poprzez dostarczanie inżynierom najnowocześniejszych narzędzi, które pozwolą im sprostać nawet najbardziej wymagającym projektom. Dodanie półsztywnych przegubów w rozszerzeniu Połączenia stalowe jest odzwierciedleniem naszego zaangażowania w innowacje, zapewniające naszym użytkownikom dostęp do najnowszych osiągnięć w technologii analizy statyczno-wytrzymałościowej.

Dzięki przegubom półsztywnym można teraz symulować połączenia stalowe z większą precyzją, dzięki czemu obliczenia są lepiej dostosowane do rzeczywistego zachowania. Ta nowa funkcja umożliwia inżynierom przenoszenie projektów na wyższy poziom, oferując elastyczność, dokładność i niezawodność niezbędną do odniesienia sukcesu w dzisiejszym wymagającym środowisku budowlanym.

Włączenie przegubów półsztywnych do projektów konstrukcyjnych gwarantuje, że projekty będą nie tylko solidne konstrukcyjnie, ale także zoptymalizowane pod kątem wydajności i opłacalności. Dzięki możliwości obliczania sztywności wielu połączeń w całej konstrukcji program RFEM 6 jest rozwiązaniem typu "wszystko w jednym". Korzystając z tej funkcji, można stawiać czoła złożonym wyzwaniom z większą precyzją i projektować bezpieczniejsze i bardziej wydajne konstrukcje, w pełni wykorzystując innowacyjne narzędzia oferowane przez program RFEM 6.

.png?mw=760&hash=533386949b33be7701eab5961d3eda50616ffec8)